3 Danger Signs of Boiler Operation You Should Never Ignore

Did you know that most industrial boiler explosions could have been prevented with just 3 simple checks per shift? In this article, we’ll walk you through the most critical danger signs of industrial boiler operation — and how to identify and fix them before it’s too late.

Includes: practical tips, checklist, technical images, and a video demo from DIVI Group

Why You Should Pay Attention to Danger Signs of Industrial Boiler Operation

Serious consequences when boiler safety warning signs are ignored during operation.

Serious consequences when boiler safety warning signs are ignored during operation. Industrial boilers are among the most high-pressure systems in any manufacturing facility and pose serious risks if not properly controlled. However, due to the routine nature of daily tasks, many boiler operators tend to overlook early warning signs, which can lead to avoidable incidents.

According to statistics from various occupational safety inspection agencies, over 60% of boiler explosion incidents are caused by the failure to detect critical danger signs of industrial boiler operation — such as jammed safety valves, faulty water level sensors, or excessive sludge buildup.

Being proactive in identifying abnormal signs not only helps prevent potential boiler explosions but also ensures operator safety, extends equipment lifespan, and reduces production losses.

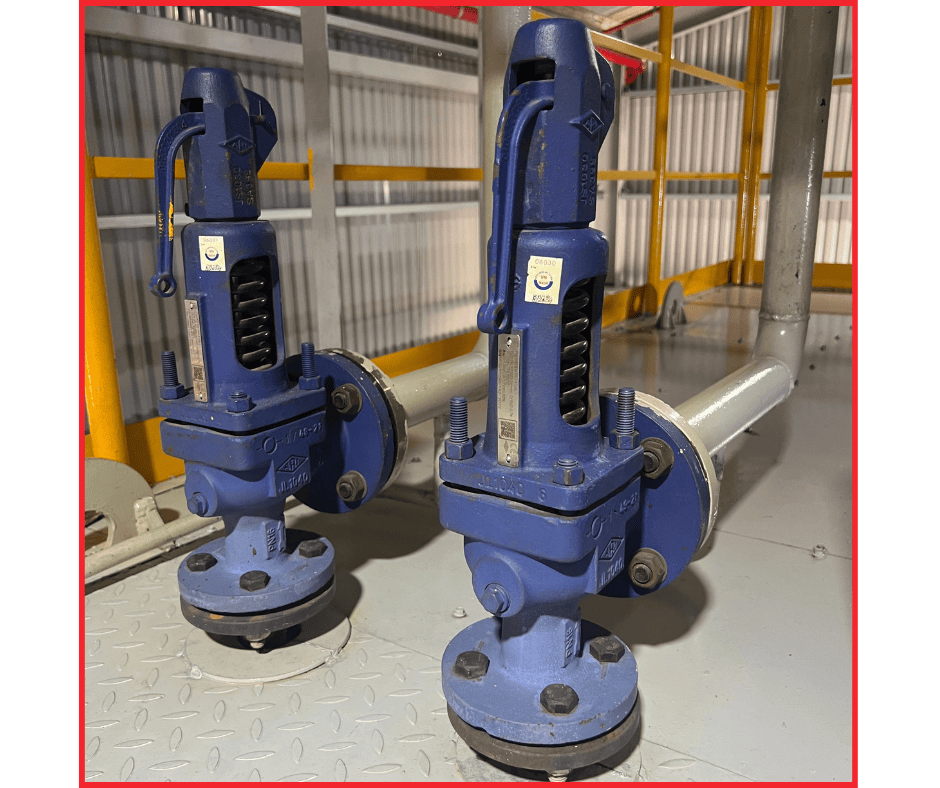

Sign 1: Safety Valve Malfunction – A Critical Risk Often Overlooked

Safety valves are essential protection devices in every industrial boiler system.

Safety valves are essential protection devices in every industrial boiler system. In every industrial boiler system, the safety valve is a mandatory protection component that acts as the last line of defense when internal pressure exceeds the design limit.

When the valve gets stuck, fails to release, or continuously leaks steam without stopping, it becomes one of the most serious yet commonly ignored danger signs of industrial boiler operation.

How to quickly identify this issue:

-

When boiler pressure exceeds 80% of the setpoint, perform a manual lift test by pulling the valve lever.

- If there’s no steam discharge, or the valve keeps discharging even after release, it indicates a failure of the pressure relief function.

Potential hazards:

-

Uncontrolled pressure rise can lead to localized overpressure, causing pipe ruptures, boiler shell cracking, or vessel explosions.

- In severe cases, the boiler completely loses its built-in protective function and becomes a high-risk device that threatens both operational safety and human life.

Important Note: Safety valves must be inspected at the beginning of each shift following proper technical guidelines. Never operate the boiler if there is any doubt about the functionality of this component.

Sign 2: Lack of a Water-Level Alarm System

Water loss inside a boiler is one of the most common and dangerous causes of sudden boiler explosions. When a boiler operates without sufficient water, the sudden temperature rise causes the pressure-bearing tubes to overheat, become brittle, and crack. Reintroducing water into these overheated areas can result in violent tube ruptures due to thermal shock.

This is a critical danger sign of industrial boiler operation that many operators overlook — especially if the boiler water level alarm system fails to function properly.

Recommended water alarm system configuration includes:- Water gauge glass for visual monitoring of the boiler water level.

- Electrode probes or float sensors to detect actual water levels.

- Blowdown valve for testing the accuracy of the signal readings.

- Alarm buzzer, signal lights, and auto feedwater pump that activate when the water level drops below the safety threshold.

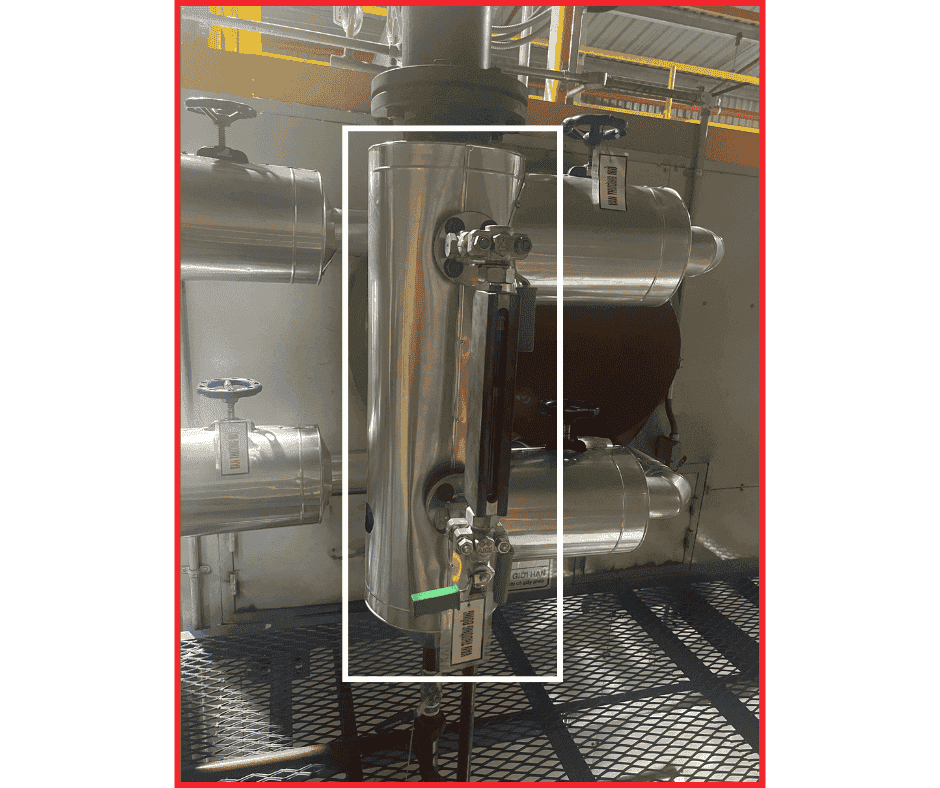

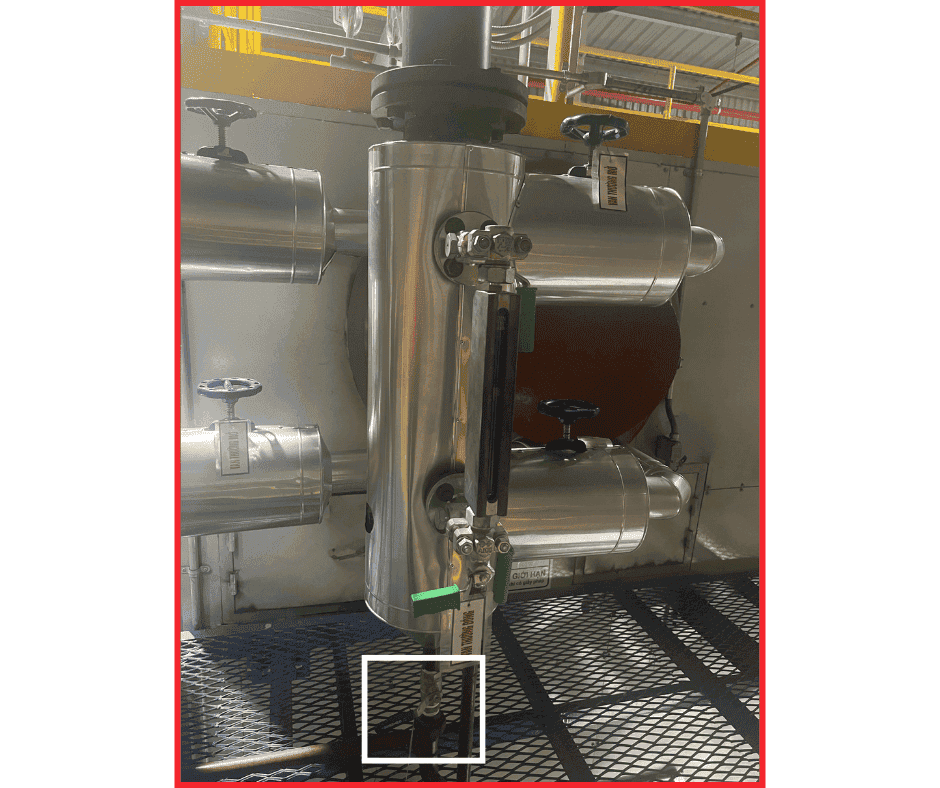

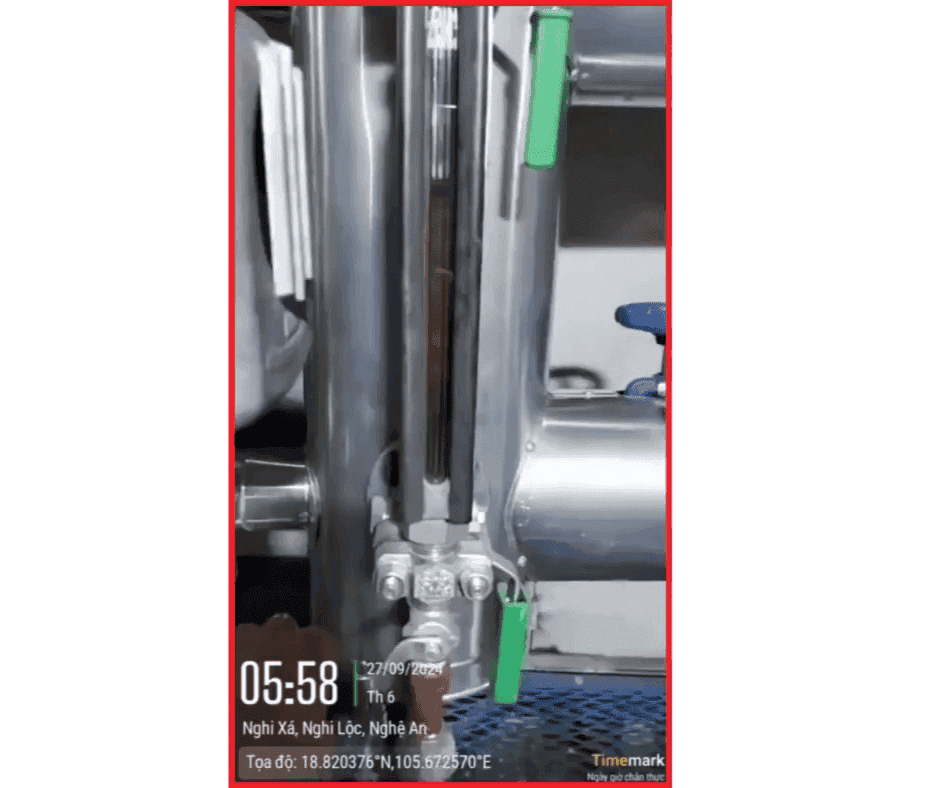

The sight glass is an essential device for monitoring water levels in industrial boilers.

The sight glass is an essential device for monitoring water levels in industrial boilers.  The float sensor detects low water levels and triggers alarms and feedwater pumps accordingly.

The float sensor detects low water levels and triggers alarms and feedwater pumps accordingly.  The blowdown valve should be opened every shift to verify that the sight glass shows accurate water levels.

The blowdown valve should be opened every shift to verify that the sight glass shows accurate water levels.  The audible and visual alarm system helps detect low water levels early in boiler operation.

The audible and visual alarm system helps detect low water levels early in boiler operation.  The automatic feedwater pump must operate promptly to prevent sudden boiler dry-out incidents.

The automatic feedwater pump must operate promptly to prevent sudden boiler dry-out incidents. Important note: If even one of these four components is missing or malfunctioning, the risk of uncontrolled water loss becomes extremely high — making it one of the leading causes of boiler explosions.

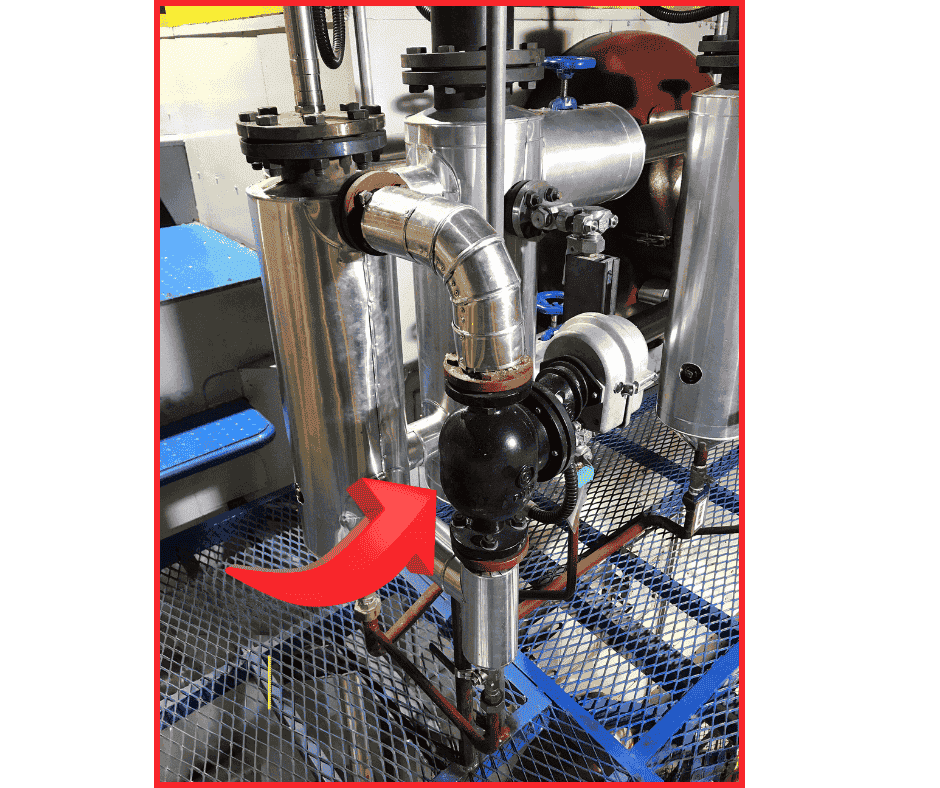

Sign 3: Skipping Daily Blowdown – A Hidden Operational Hazard

During operation, boiler feedwater often contains dissolved solids such as calcium and magnesium ions—even after pretreatment. As temperature rises, these impurities settle and form sludge and scale at the bottom of the boiler.

Failing to perform blowdown regularly is a critical danger sign of industrial boiler operation that can lead to serious consequences over time.

Risks of skipping blowdown:- Reduced heat transfer efficiency, resulting in thermal pressure imbalance.

- Increased fuel consumption and significantly higher operating costs.

- Sludge accumulation may cause boiler base bulging or cracking in high-pressure zones.

- Blow down the boiler 1–2 times per shift, opening the valve for 10–30 seconds each time.

- If no water is discharged or only weak flow is observed, the blowdown valve may be clogged and should be checked immediately.

Important Note: Sludge and scale don’t just waste fuel—they can create false internal pressure readings. If actual pressure is not accurately detected, the system may fail to respond in time. This is one of the leading causes of boiler explosions that many operators still underestimate.

Quick Boiler Safety Checklist (Per Shift)

| Component | How to Check | Frequency |

|---|---|---|

| Safety Valve | Manually lift when pressure > 80% | Every shift |

| Water Level | Open blowdown valve and check signal | Every shift |

| Blowdown | Open valve for 10–30 seconds | 1–2 times/shift |

Don’t Ignore the Warning Signs — Take Action Before It’s Too Late

After handling hundreds of real-life incidents, DIVI has found that most boiler-related accidents can be completely avoided — if operators pay attention to danger signs of industrial boiler operation from the very beginning.

We’ve witnessed factories suffer major losses simply because they skipped safety valve checks, neglected daily blowdown, or lacked a proper low-water alarm system.

Don’t wait until your boiler explodes, causes equipment damage, property loss, or worse — injuries or fatalities.

DIVI is committed to partnering with your business in establishing safe, standardized, and effective boiler operation practices.

Contact our technical team now to:

- Receive expert advice on standardized boiler operation procedures

- Get training on how to properly inspect and maintain all critical boiler safety components

- Update your plant with preventive solutions to eliminate root causes of boiler failure

Act now — for a safer, more efficient, and sustainable industrial boiler system for your facility.

Final Thoughts:

If your boiler is currently operating and you:

- Do not check the safety valve every shift,

- Do not have a reliable low-water alarm system installed,

- And do not perform daily blowdown...

Then you're working with a system that’s essentially a ticking time bomb.

DIVI has personally handled numerous cases of boiler explosions, fire hazards, and high-pressure leaks caused by basic oversights. That’s why we strongly urge you:

Never underestimate small routine checks — they are your greatest line of defense for plant and personnel safety.

If you found this article helpful, please share it with your boiler operators or anyone managing industrial steam systems, so we can together build a safer, more cost-efficient, and reliable boiler operation environment.

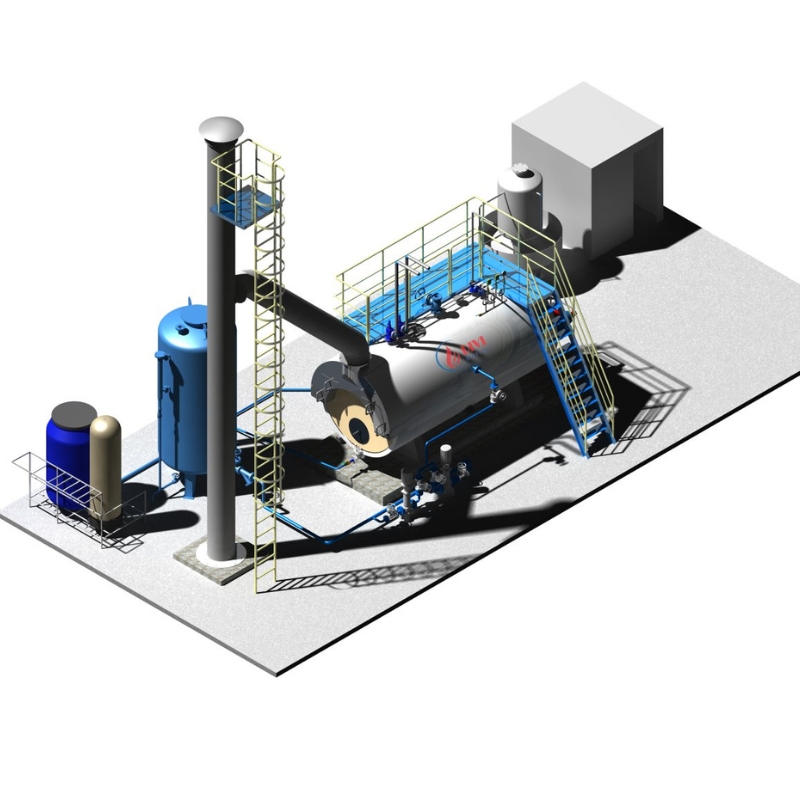

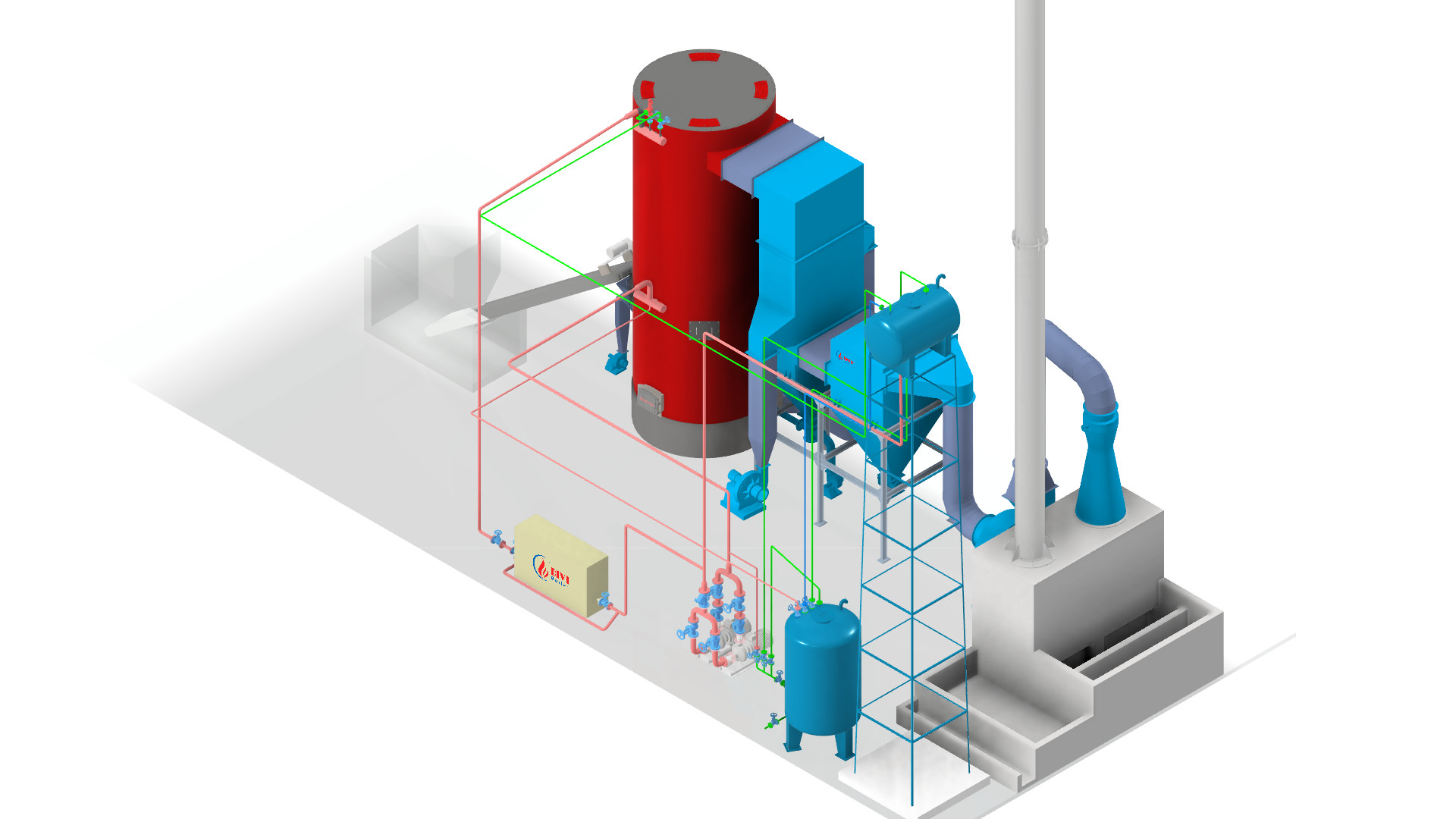

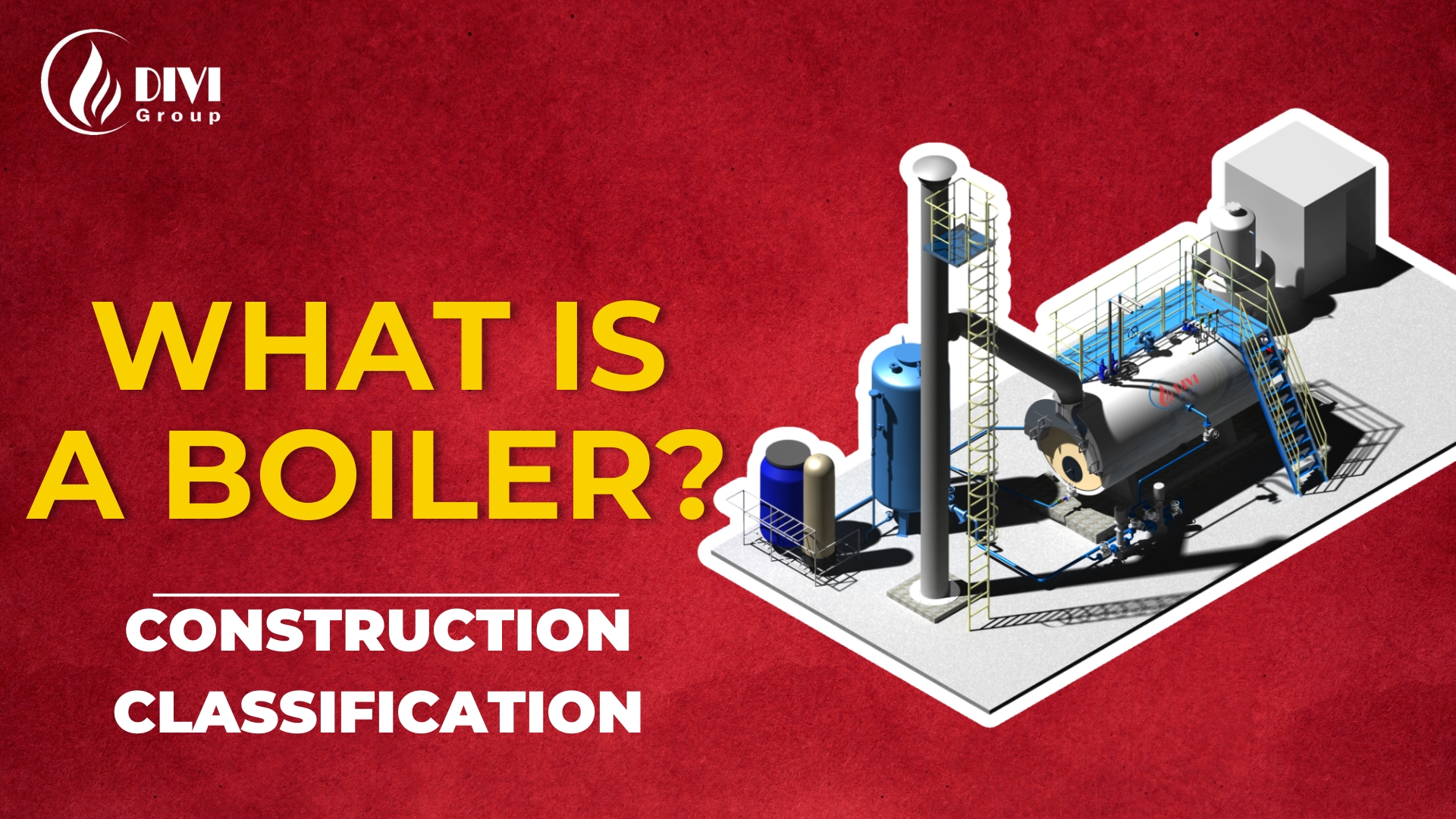

DIVI Group's Boiler Products:

Other news

-

Steam Separator – An Effective Solution for Dry Steam

29/12/2025, -

Treating High CO Emissions in Fixed-Grate Boilers – Is Boiler Replacement Necessary? Practical Solutions from DIVI

18/12/2025, -

What Is a Steam Trap? Principles, Types, and How to Select the Right Steam Trap for Your Steam System

07/12/2025, -

COMPARISON OF STEAM TRAPS: PRINCIPLES – EXPERIMENTS – OPTIMAL SELECTION FOR STEAM SYSTEMS

29/11/2025, -

Compact Biomass-Fired Boiler DVG-VN – The Optimal Fossil-Fuel Replacement Solution for Factories

23/11/2025, -

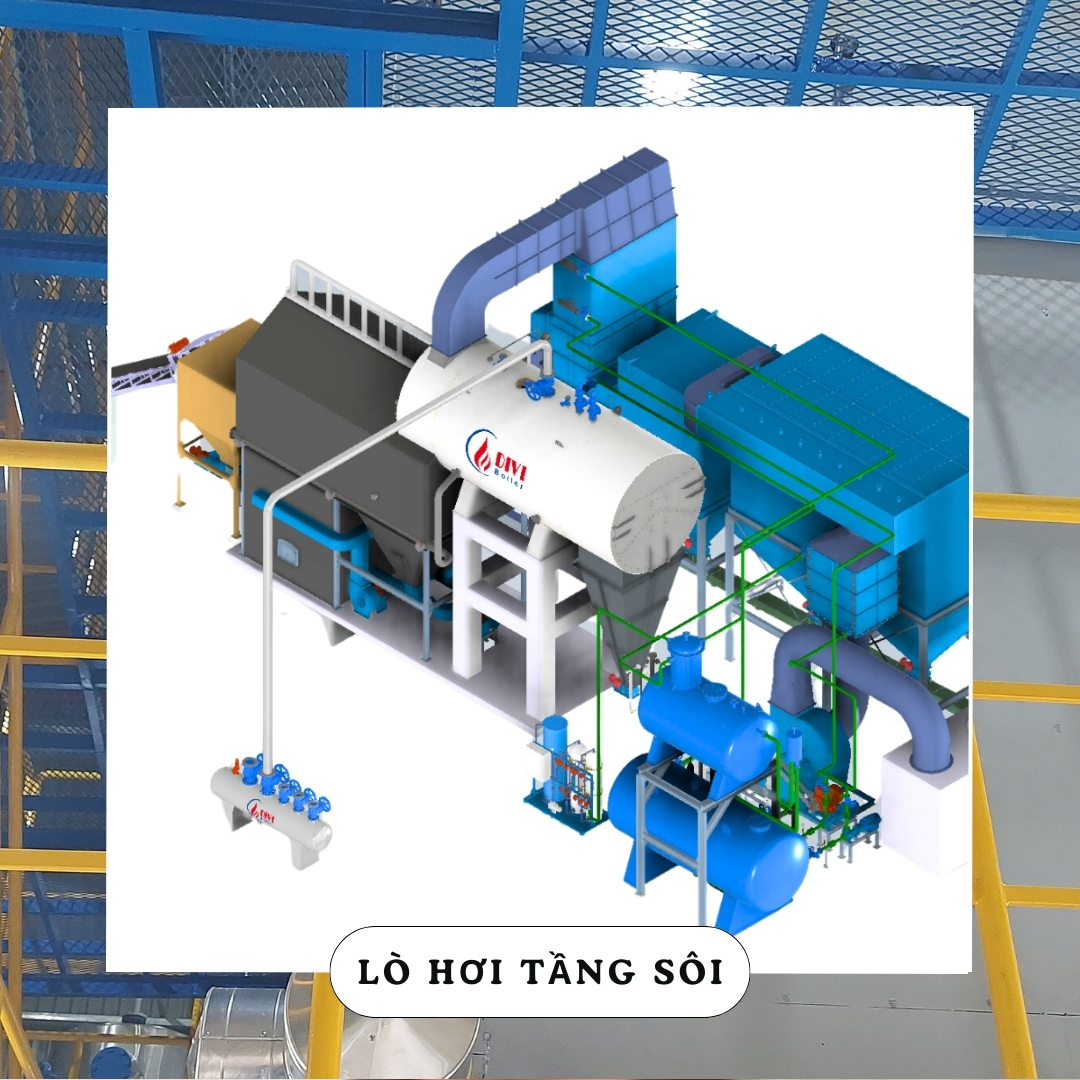

Which Boiler Should You Choose: Fixed Grate or Fluidized Bed? Detailed Efficiency, Cost & Environmental Comparison

24/06/2025, -

5 Common Mistakes in Industrial Steam Distribution Systems

11/06/2025, -

Mr. Boiler Speaks: Wake-Up Call from an Industrial Icon

09/06/2025, -

What is a Thermal Oil Heater? Structure, Benefits & Safety Tips

27/05/2025, -

7 Common Causes of Boiler Flue Gas Issues – Effective Treatment Solutions

08/05/2025,

EN

EN