What Is an Industrial Boiler?

Have you ever wondered what an industrial boiler is and why it plays such a critical role in factories and plants? In this article, we’ll demystify industrial boilers, explaining their structure, how they work, and their importance in various industries. Let’s dive in!

What Is an Industrial Boiler?

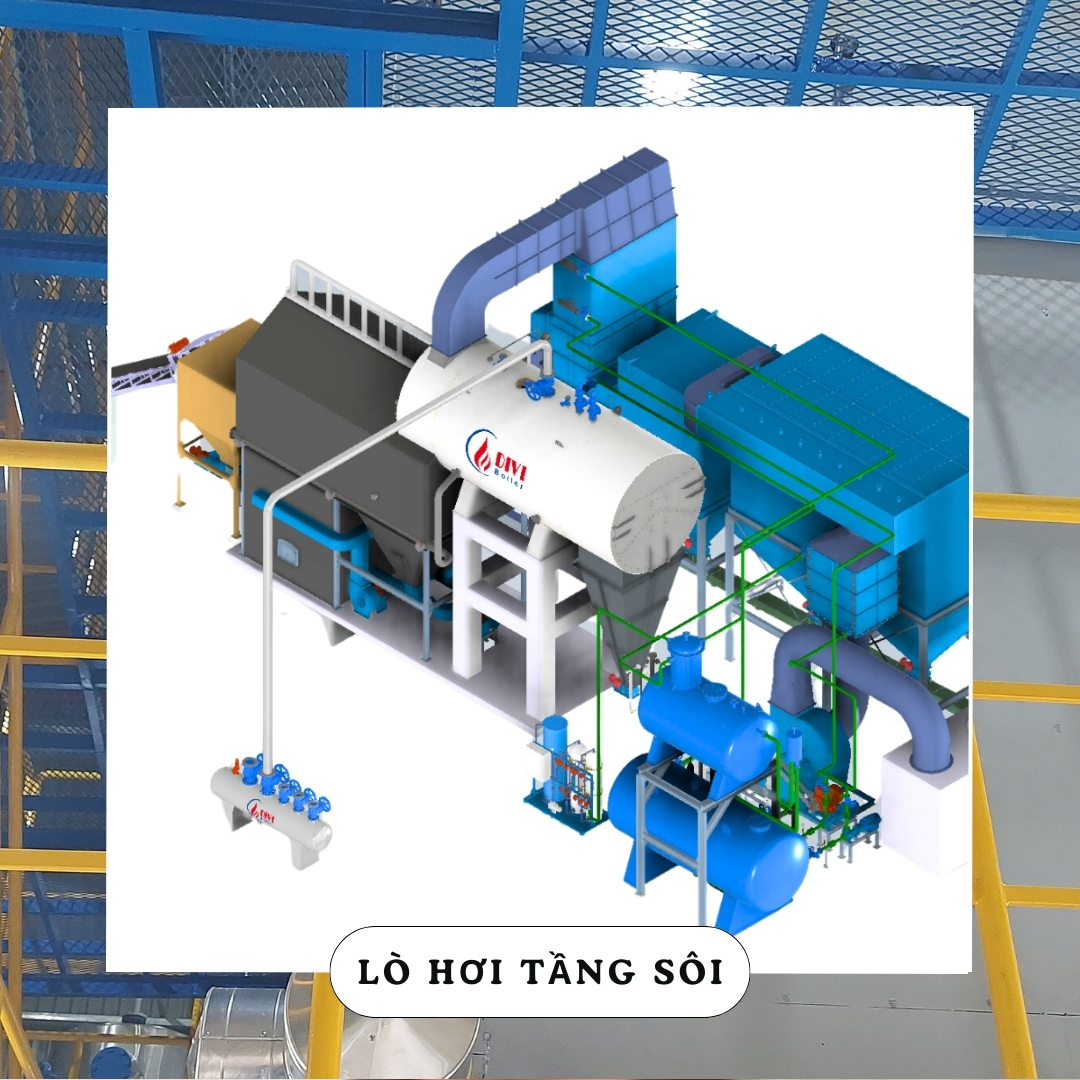

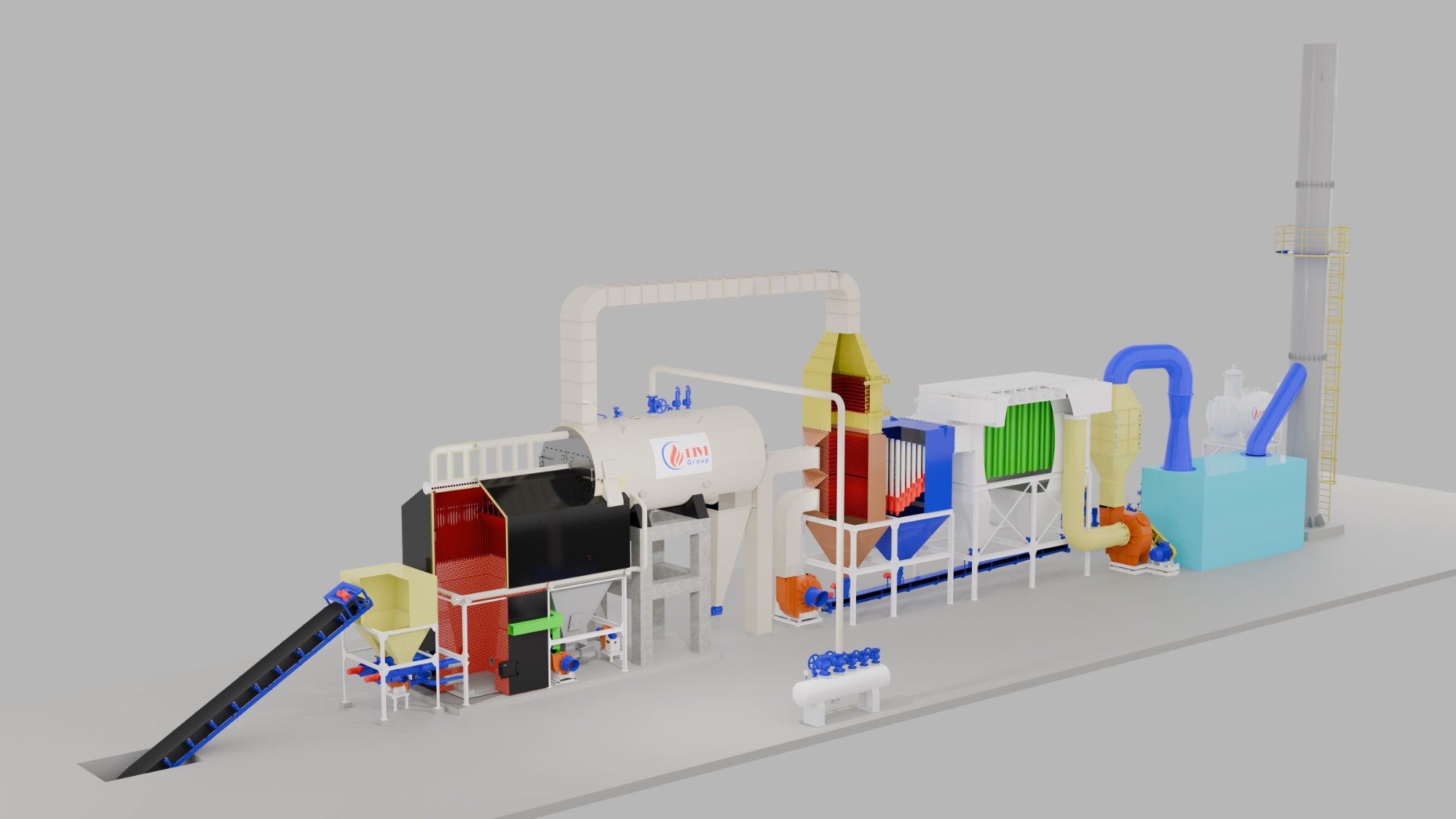

Fluidized Bed Industrial Boiler by DIVI GROUP

Fluidized Bed Industrial Boiler by DIVI GROUPAn industrial boiler is a specialized boiler system designed to heat water and convert it into steam or hot water for use in industrial processes. A typical steam boiler operates under high pressure to meet the demands of sectors such as manufacturing, food processing, textiles, and pharmaceuticals. This type of boiler is crucial for maintaining continuous production and optimizing energy use.

Core functions of an industrial boiler include:

-

Generating high-pressure steam or hot water for industrial applications

-

Supporting stable, round-the-clock production lines

-

Boosting operational efficiency and energy savings

By integrating a high-quality industrial boiler, businesses can ensure reliability, safety, and compliance with modern industry standards.

II. How Does an Industrial Boiler Work?

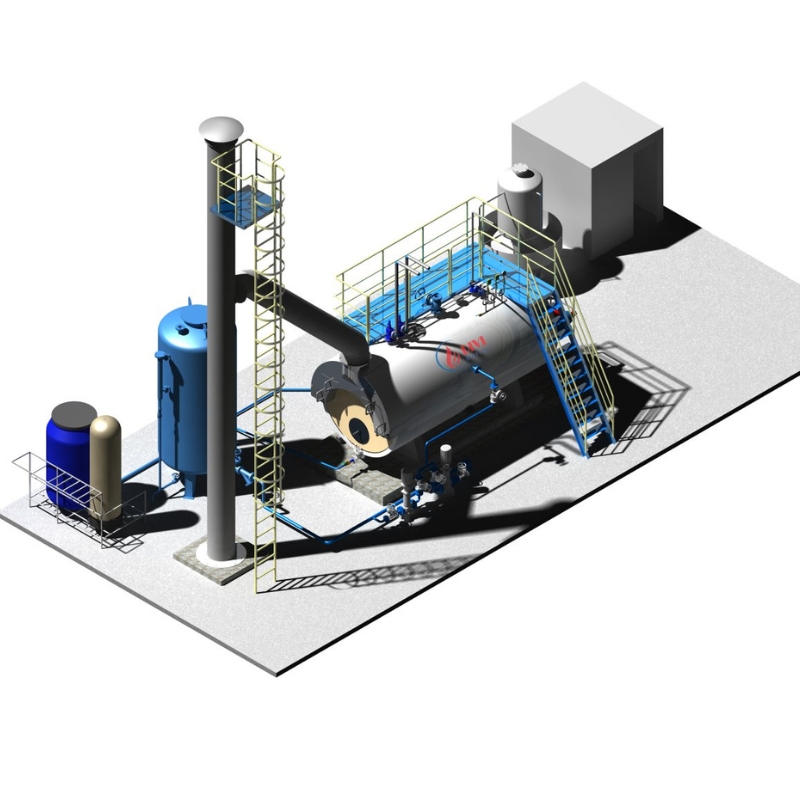

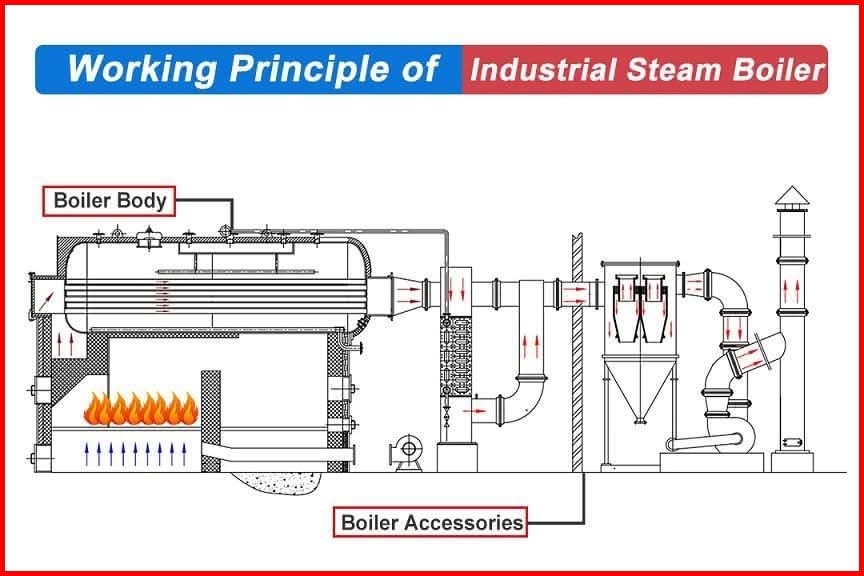

How an Industrial Boiler Operates with High Steam Efficiency

How an Industrial Boiler Operates with High Steam EfficiencyThe working principle of an industrial boiler revolves around converting energy from fuel combustion into usable steam or hot water. This process is fundamental to industries where a steam boiler is needed for continuous production.

A typical industrial boiler system follows these key steps:

Fuel Combustion:

The boiler burns fuel such as coal, oil, natural gas, or biomass in the combustion chamber (also called the furnace). This is where the primary heat source is generated.

Heat Transfer:

The intense heat passes through heat exchanger tubes, transferring thermal energy to the surrounding water within the boiler shell. In a steam boiler, the water absorbs this heat until it reaches boiling point.

- Steam Generation: As the water boils, it transforms into high-pressure steam. This steam collects in the steam drum, where it's ready for use.

- Distribution: The generated steam travels through a network of pipelines, supplying energy to various industrial processes, such as heating, sterilization, or mechanical work.

1. Main Components of an Industrial Boiler:

-

Furnace (Combustion Chamber): Where fuel is burned to produce heat.

-

Heat Exchanger Tubes: Transfer heat from combustion gases to water.

-

Steam Drum: Collects and stores produced steam.

-

Water Feed System: Maintains optimal water levels inside the boiler.

-

Safety Valves & Controls: Ensure pressure and temperature remain within safe limits.

2. Why the Process Matters:

The efficiency of a steam boiler directly impacts production output and operational costs. A well-designed industrial boiler ensures:

-

Maximum heat transfer efficiency

-

Minimal fuel consumption

-

Stable and safe steam supply

By understanding the principle of operation, industries can optimize boiler performance and reduce downtime, ensuring smooth, uninterrupted production.

III. Quick Overview of Boiler Types

Industrial operations require different boiler systems depending on their production needs. Here’s a quick overview of common industrial boiler types, each with unique benefits:

Fire-tube Boilers

In this type of industrial boiler, hot gases pass through tubes surrounded by water. Suitable for low to medium pressure steam applications.

Water-tube Boilers

The opposite of fire-tube, these boilers circulate water through tubes heated externally by combustion gases. Ideal for high-pressure steam boiler applications in power plants and large factories.

Electric Boilers

A clean, emission-free option. These boilers use electric energy to heat water, making them perfect for environments requiring minimal pollution.

Biomass Boilers

These industrial boilers burn organic materials like wood chips, rice husks, or pellets. A sustainable option aligned with green energy goals.

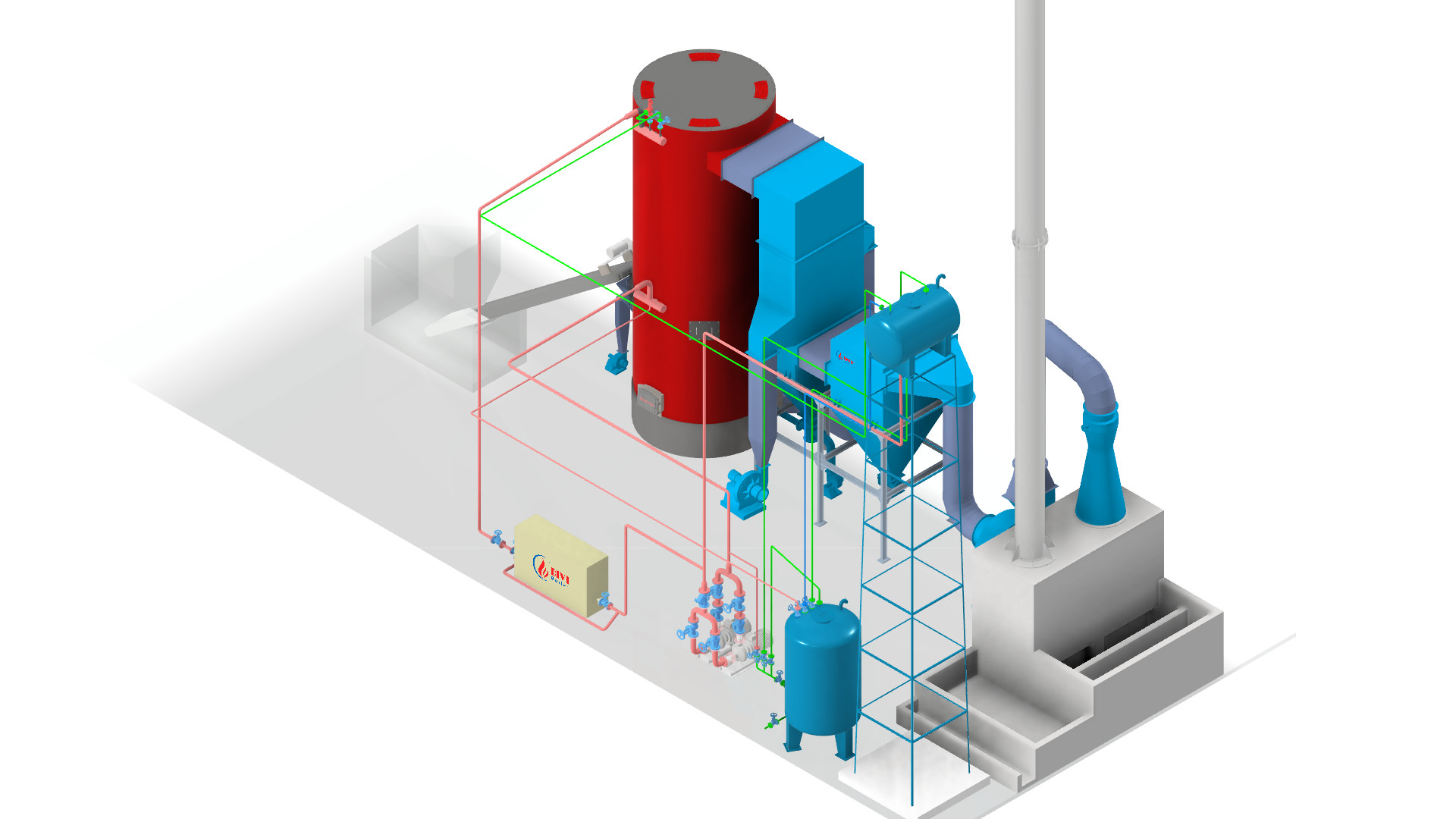

Fluidized Bed Combustion (FBC) Boilers

Advanced steam boiler technology that burns fuel in a bed of sand or ash, suspended by air. Known for high combustion efficiency and low emissions, making it ideal for industries seeking eco-friendly solutions.

Each boiler type is designed to meet specific operational demands—choosing the right industrial boiler ensures optimal performance, energy savings, and compliance with environmental standards.

IV. Applications of Industrial Boilers

Industrial boilers play a critical role in many industries by providing reliable steam and hot water for core production processes. Here’s how different sectors rely on boiler systems:

1. Food & Beverage Industry

Use of steam boilers for sterilization, cooking, pasteurization, and cleaning. These processes demand consistent, high-quality steam to maintain hygiene and safety standards.

Food & Beverage Industrial

Food & Beverage Industrial2. Textile Industry

Textile Industry

Textile IndustryIndustrial boilers supply steam for dyeing, drying, and fabric processing. The uniform heat distribution ensures color consistency and fabric strength.

3. Pharmaceutical Industry

Sterile steam generation is vital for sterilization of equipment and production environments. Boilers also support controlled heating in manufacturing and laboratory setups.

4. Power Generation

High-capacity industrial boilers produce steam that drives turbines for electricity generation, especially in thermal power plants.

5. Chemical Industry

Boilers provide essential process heating for reactors, distillation columns, and mixing vessels. A well-designed steam boiler system supports chemical reactions and maintains precise temperatures.

Chemical Industry

Chemical IndustryV. Advantages of Using Industrial Boilers

Key Advantages of Using Industrial Boilers

Key Advantages of Using Industrial BoilersInvesting in a high-quality industrial boiler brings significant advantages for businesses across sectors. Here’s why a well-designed boiler system is essential:

1. High Efficiency

Modern steam boilers offer superior thermal transfer, ensuring fast steam production. This boosts productivity and reduces energy waste.

2. Scalability

Whether your factory is small or large, an industrial boiler can be customized to fit your exact operational needs. This scalability supports long-term growth.

3. Energy Flexibility

Today’s boiler systems are compatible with a wide range of fuel types—coal, biomass, gas, and oil. This allows businesses to switch fuels easily based on cost and sustainability goals.

4. Compliance & Safety

A modern industrial boiler is designed to meet international safety and emissions standards. Built-in safety controls and automatic monitoring reduce risks and ensure legal compliance.

By choosing the right steam boiler, you ensure efficient, safe, and sustainable operations that meet both production and environmental targets.

Why Choose DIVI GROUP ?

Looking for a trusted partner for your industrial boiler needs? Here’s why DIVI GROUP stands out as the top choice in Southern Vietnam.

Founded in 2011, DIVI GROUP specializes in the design, manufacturing, installation, and technology transfer of industrial boilers and steam boiler systems. Our in-house team delivers end-to-end solutions—from concept to commissioning—ensuring maximum efficiency and cost savings for your business.

We focus on producing high-efficiency boiler systems tailored to each client's requirements. Our advanced designs support renewable fuel sources like rice husks, sawdust, and coffee shells, helping you cut operational costs while reducing environmental impact.

DIVI GROUP Industrial Boiler Company

DIVI GROUP Industrial Boiler CompanyOur full-service portfolio includes:

-

Industrial Boilers & Steam Boilers

-

Thermal Oil Heaters (Heat Transfer Boilers)

-

Steam Supply Services (Industrial Steam Sales)

-

Boiler Rental Services

-

Boiler Maintenance & Repair

-

Boiler & Thermal Oil System Upgrades

Choosing DIVI GROUP means partnering with a boiler manufacturer that prioritizes safety, efficiency, and environmental compliance. We are committed to helping your business optimize performance, lower energy costs, and meet strict safety standards.

Maintenance & Safety Guidelines

Proper maintenance of an industrial boiler is essential to ensure safe, efficient, and long-lasting operation. A well-maintained boiler system reduces the risk of failures, minimizes downtime, and ensures compliance with safety standards.

Key maintenance tasks include:

-

Routine Inspections and Cleaning

Regularly inspect your steam boiler for signs of wear, leaks, and residue buildup. Cleaning the internal components helps maintain optimal heat transfer. -

Pressure and Temperature Monitoring

Continuously check the boiler’s pressure and temperature to ensure it operates within safe limits. Abnormal readings can indicate potential issues. -

Safety Valve Testing

Test safety valves periodically to confirm they function correctly. These valves are crucial for preventing dangerous overpressure situations. -

Automation and Control System Checks

Update and test the boiler’s automation systems to maintain precise control over fuel supply, water levels, and steam output.

By following these guidelines, your industrial boiler will deliver reliable steam production, enhance workplace safety, and extend equipment lifespan.

FAQs

1. What is the typical lifespan of an industrial boiler?

A well-maintained industrial boiler typically lasts 15 to 25 years, providing consistent steam and hot water output for industrial processes.

2. Can biomass fuel be used in a steam boiler?

Yes, most modern steam boilers and industrial boilers are compatible with biomass fuels like rice husks, wood pellets, and sawdust, making them eco-friendly and cost-effective.

3. How often should a boiler be serviced?

To ensure safety and efficiency, every boiler system should undergo professional maintenance at least once a year, with routine checks on pressure, valves, and automation systems.

4. What’s the difference between a fire-tube and a water-tube boiler?

A fire-tube boiler circulates hot gases through tubes, while a water-tube boiler circulates water inside tubes. Water-tube designs handle higher pressure steam, ideal for large industrial setups.

5. How do I choose the right industrial boiler?

Evaluate your steam/hot water demand, fuel options, and installation space. Consult a trusted boiler expert to select an efficient and compliant boiler system tailored to your needs.

Conclusion

In conclusion, an industrial boiler is a vital component of modern industrial operations, providing essential steam and hot water for critical processes. By understanding how a boiler system works and selecting the right type, your business can achieve maximum efficiency, cost savings, and environmental compliance.

Contact DIVI GROUP today for expert consultation and discover how our high-performance industrial boilers can transform your operations. Don’t miss the opportunity to boost your productivity with safe, reliable, and eco-friendly steam boiler solutions!

Related Articles:

Additional Reference Videos:

All About Steam Boilers – A Beginner’s Guide to Boiler Types

[DIVI] Boiler safety and practices for safe operation

DIVI Group's Boiler Products:

Other news

-

Steam Separator – An Effective Solution for Dry Steam

29/12/2025, -

Treating High CO Emissions in Fixed-Grate Boilers – Is Boiler Replacement Necessary? Practical Solutions from DIVI

18/12/2025, -

What Is a Steam Trap? Principles, Types, and How to Select the Right Steam Trap for Your Steam System

07/12/2025, -

COMPARISON OF STEAM TRAPS: PRINCIPLES – EXPERIMENTS – OPTIMAL SELECTION FOR STEAM SYSTEMS

29/11/2025, -

Compact Biomass-Fired Boiler DVG-VN – The Optimal Fossil-Fuel Replacement Solution for Factories

23/11/2025, -

Which Boiler Should You Choose: Fixed Grate or Fluidized Bed? Detailed Efficiency, Cost & Environmental Comparison

24/06/2025, -

5 Common Mistakes in Industrial Steam Distribution Systems

11/06/2025, -

Mr. Boiler Speaks: Wake-Up Call from an Industrial Icon

09/06/2025, -

What is a Thermal Oil Heater? Structure, Benefits & Safety Tips

27/05/2025, -

3 Danger Signs of Boiler Operation You Should Never Ignore

24/05/2025,

EN

EN