COMPARISON OF STEAM TRAPS: PRINCIPLES – EXPERIMENTS – OPTIMAL SELECTION FOR STEAM SYSTEMS

Have you ever seen a steam trap discharging “white steam everywhere” and wondered whether it is operating normally or malfunctioning? In this article, we compare steam trap types based on real tests performed at DIVI’s workshop, where a 1-ton/hour boiler was operated to directly test the three most common steam traps. This helps you clearly understand the mechanism, discharge capacity, and proper application of each type.

I. Overview of the Real-world Experiment at DIVI

DIVI conducted experiments simulating actual factory operating conditions, where steam is used continuously and condensate varies according to load. By operating a 1-ton/hour boiler and routing steam through a heat exchanger system to generate real condensate, engineers observed the discharge cycle, flow rate, and response of each steam trap under industrial-equivalent conditions. This data-driven approach provides accurate, objective, and highly reliable evaluations—far superior to the typical theoretical explanations found on the market.

Steam trap experiment

Steam trap experiment1. System Description

In this test, DIVI used:

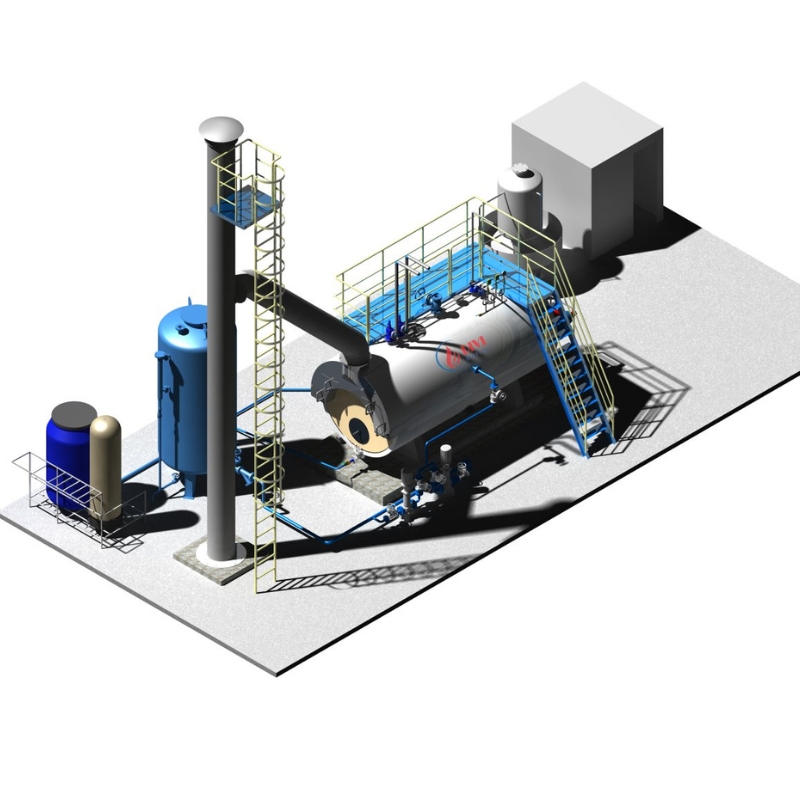

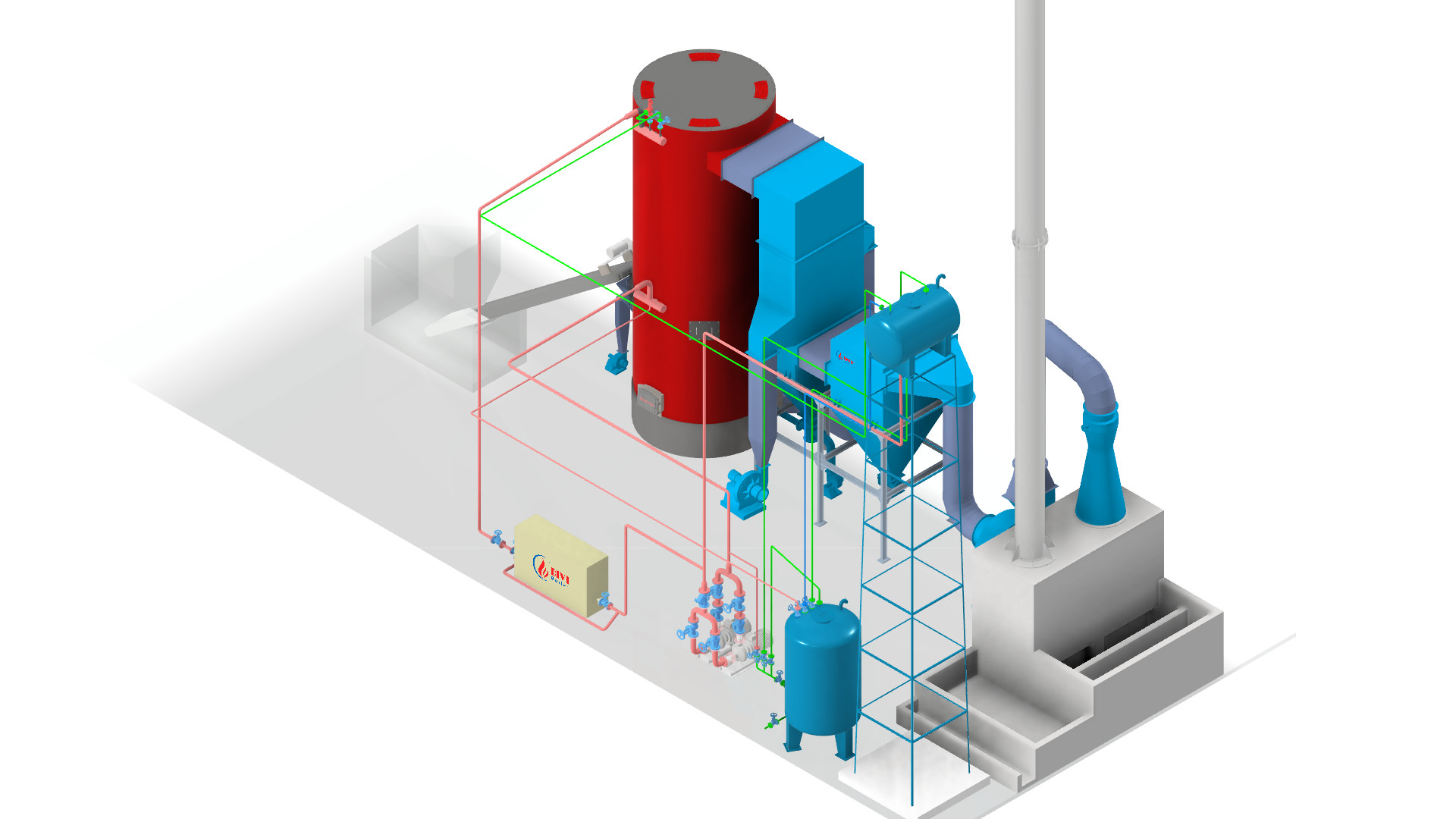

- Compact pellet-fired boiler

- Capacity: 1 ton steam/hour

- Design pressure: 12 bar

- Actual operating pressure: 10 bar

- Compact size, space optimized

- Equipped with full national safety standards

Steam from the boiler passes through:

- Heat exchanger system

- Generates real condensate

- Discharged through 3 steam trap types: Float trap, Thermodynamic (disc) trap and Inverted bucket trap

Throughout the process, DIVI also provided hands-on training for engineers and students to understand steam operation visually.

2. Purpose of the Experiment

During the test, DIVI recorded the discharge cycle of each trap to evaluate differences in flow rate, response time, and stability under varying loads. The engineers also analyzed a common issue: “Why is the trap discharging all white steam?”, determining whether it is flash steam or live steam. The results form the basis for DIVI to recommend appropriate trap selection for each load, equipment type, and condensate level, and propose solutions to reduce steam loss, improve efficiency, and save fuel.

II. Comparison of Steam Trap Types Based on DIVI Experimental Data

This is the most important section: real-world data, not textbook theory.

1. So sánh các loại bẫy hơi theo chu kỳ xả

1. Comparison by Discharge Cycle

Float Trap

- Always partially open

- Continuous, strong discharge

Disc (Thermodynamic) Trap

- Discharges in strong bursts

- Closes immediately afterward

Inverted Bucket Trap

- Discharges in cycles

- Cycles are clear and stable

2. Comparison by Condensate Flow Rate

| Steam Trap Type | Discharge Flow Rate | Suitable Application |

|---|---|---|

| Float Trap | Highest | Points with high condensate load |

| Inverted Bucket Trap | Medium | Stable load, not too high |

| Disc Trap | Lowest | Small discharge points, low load |

3. Stability Under Load Variation

- Strong load fluctuation: Float trap

- Stable, continuous load: Inverted bucket trap

- Low load / small drain points: Disc trap

4. Summary Comparison Table

| Criteria | Float Trap | Disc Trap | Inverted Bucket Trap |

|---|---|---|---|

| Discharge Cycle | Continuous | Intermittent bursts | Cyclic |

| Discharge Flow | Very high | Low | Medium |

| Stability | Very stable | Strongly affected by ambient heat | Very stable |

| Durability | Medium | High | Very high |

| Suitable Load | Large | Small | Medium – Large |

| Drawbacks | Easily damaged by dirty water | Heat-sensitive, cycle may fluctuate | Not suitable for very large flows |

III. Why Do You See Steam Traps Discharging All White Steam?

White steam discharge phenomenon of steam traps

White steam discharge phenomenon of steam traps

This is the question 90% of factory technicians misunderstand. In DIVI’s real tests, all three traps discharged white steam.

1. White steam = flash steam, not live steam

Condensate at 3 bar has a temperature of 143.6°C. When released to the atmosphere at 1 bar:

- Pressure drops instantly

- Part of the hot condensate flashes into steam

- Creates “flash steam”

→ It looks like the trap is blowing steam, but the trap is working correctly.

2. When is this phenomenon normal?

In cases where the steam trap is operating normally, you will observe that the discharge cycle follows the designed characteristics without being prolonged or disrupted. The internal mechanism responds quickly and sensitively to the incoming condensate, opening and closing smoothly and consistently. At the same time, the inlet and outlet temperatures remain within the proper range for each trap type, with no abnormal deviations. Lastly, the trap shows no signs of vibration, hammering, or loud noise, indicating that the system is functioning correctly and in accordance with proper technical operation.

3. When is it abnormal?

When a steam trap encounters a problem, you will notice clear signs such as continuous 100% discharge without following its normal cycle, indicating that live steam is being lost. Inside the trap, there is no condensate passing through or the amount is too low, preventing the valve from closing as designed. In addition, the trap often produces loud, prolonged noise, signaling that high-velocity steam is escaping directly to the atmosphere. As a result, downstream equipment receives insufficient heat, heating time becomes longer, and fuel consumption increases significantly.

IV. Ứng dụng phù hợp cho từng loại bẫy hơi

1. Float Trap – Best for:

The float trap is especially suitable for locations with a high condensate load, where continuous and stable discharge is required. This type of trap operates effectively on high-capacity dryers, heating equipment that uses modulating control valves, or any point where condensate is generated continuously according to the load. Thanks to its water-level-based opening mechanism, the float trap ensures condensate is discharged at the right moment, preventing backup and maintaining optimal heat-transfer efficiency.

Applications of Each Steam Trap Type

Applications of Each Steam Trap Type2. Disc Trap – Best for:

The thermodynamic (disc) trap is most suitable for small and scattered drain points, where condensate volume is low but requires quick and decisive discharge. This type of trap is also commonly used on long steam pipelines to remove small amounts of condensate that accumulate along the line. For small drying equipment or systems that generate minimal condensate, the disc trap performs effectively thanks to its fast open–close action, high pressure tolerance, and compact, easy-to-install construction.

3. Inverted Bucket Trap – Best for:

The inverted bucket trap is particularly suitable for systems with stable loads, where the condensate flow does not fluctuate significantly. This type of trap operates efficiently on equipment that runs 24/7, especially heat exchangers that require consistent, uninterrupted discharge cycles. With its durable mechanical construction and strong resistance to dirty steam, the inverted bucket trap becomes an ideal choice for applications requiring high durability and low maintenance frequency, helping reduce long-term operating costs.

V. Common Mistakes When Selecting Steam Traps

During the operation of a steam system, many failures and energy losses originate from improper selection or incorrect installation of steam traps. Below are the most common mistakes factories encounter, which directly affect heating efficiency, fuel costs, and equipment lifespan:

- Choosing the wrong discharge capacity

- Not accounting for startup load (sudden surge of condensate)

- Forgetting to install a Y-strainer before the trap

- Incorrect installation direction (especially for disc traps)

- Using a single trap type for the entire system

- Not checking the discharge cycle regularly

- Incorrect condensate return line elevation

Avoiding these mistakes helps the steam system operate stably, reduces energy loss, and significantly minimizes live steam leakage. By selecting the correct steam trap, installing it properly, and performing regular inspections, businesses not only ensure equipment safety but also optimize long-term operating costs.

VI. Conclusion

Real-world testing shows each trap has its own strengths and weaknesses.

Summary:

- Disc trap: Fast discharge – fast closing – low flow → small drain points

- Inverted bucket trap: Cyclic discharge → stable loads

- Float trap: Strong – continuous – high flow → equipment generating heavy condensate

This comparison helps you choose the correct steam trap for each location, optimize your steam system, and save fuel.

???? Contact DIVI now if you need steam system assessment or accurate steam trap selection for your factory.

Related Articles:

Additional Reference Videos:

[DIVI] Reveal interesting things from steam boilers from the steam room for newcomerse

[DIVI] Boiler safety and practices for safe operation

DIVI Group's Boiler Products:

Other news

-

Steam Separator – An Effective Solution for Dry Steam

29/12/2025, -

Treating High CO Emissions in Fixed-Grate Boilers – Is Boiler Replacement Necessary? Practical Solutions from DIVI

18/12/2025, -

What Is a Steam Trap? Principles, Types, and How to Select the Right Steam Trap for Your Steam System

07/12/2025, -

Compact Biomass-Fired Boiler DVG-VN – The Optimal Fossil-Fuel Replacement Solution for Factories

23/11/2025, -

Which Boiler Should You Choose: Fixed Grate or Fluidized Bed? Detailed Efficiency, Cost & Environmental Comparison

24/06/2025, -

5 Common Mistakes in Industrial Steam Distribution Systems

11/06/2025, -

Mr. Boiler Speaks: Wake-Up Call from an Industrial Icon

09/06/2025, -

What is a Thermal Oil Heater? Structure, Benefits & Safety Tips

27/05/2025, -

3 Danger Signs of Boiler Operation You Should Never Ignore

24/05/2025, -

7 Common Causes of Boiler Flue Gas Issues – Effective Treatment Solutions

08/05/2025,

EN

EN