During boiler operation, blowdown is mandatory to remove sludge, scale, and suspended solids from the water. If not properly handled, hot blowdown water can:

-

Kill microorganisms in wastewater treatment systems, severely impacting the environment.

-

Cause serious danger to operators due to high temperature and pressure.

The safe solution is to use a Blowdown System.

Currently, there are two common types:

-

Blowdown Separator (with cold water injection)

-

Blowdown Tank (self-cooling, for high pressure)

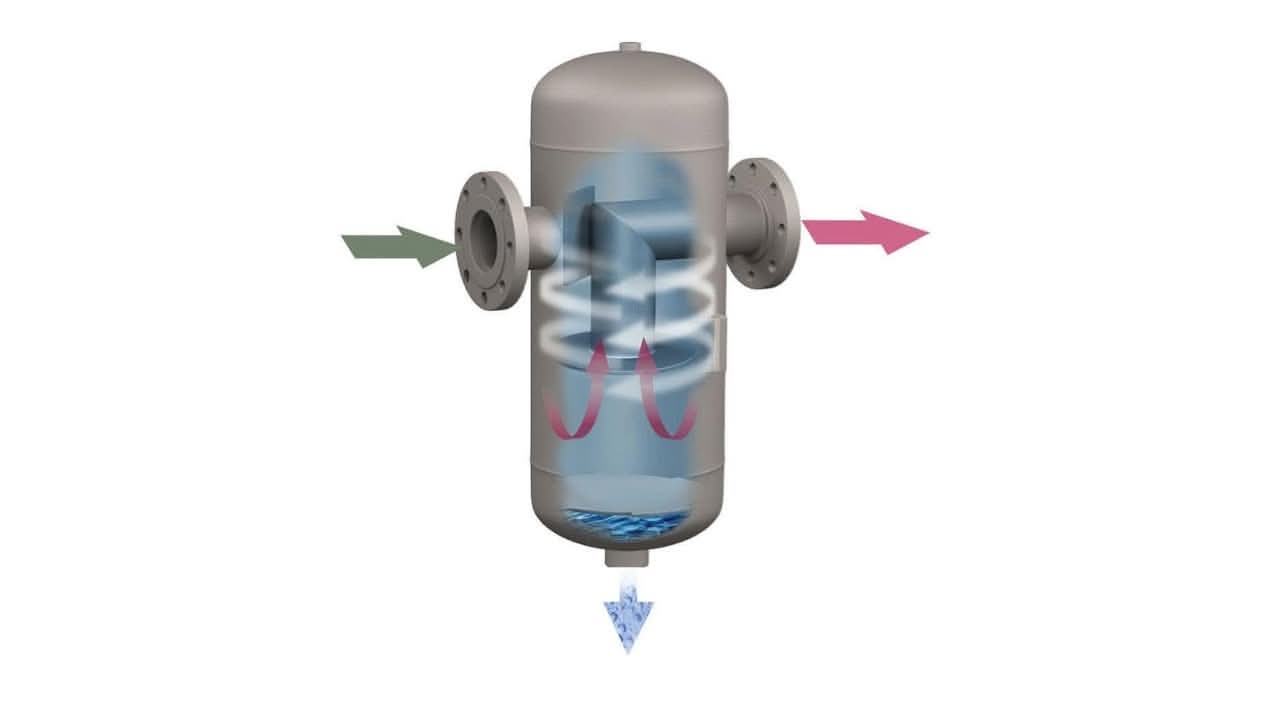

1. Blowdown Separator (Low-Pressure Type with Cold Water Injection)

Working Principle

-

Flash steam is released through a steam outlet pipe.

-

Remaining hot water is cooled by injecting cold water.

Advantages

-

Compact size.

-

Low initial investment cost.

-

Easy installation for low-pressure systems.

Disadvantages

-

Depends on a stable cold water supply.

-

Requires temperature control valves to maintain discharge water below 60°C.

-

Not suitable for high-pressure boilers or multi-boiler systems.

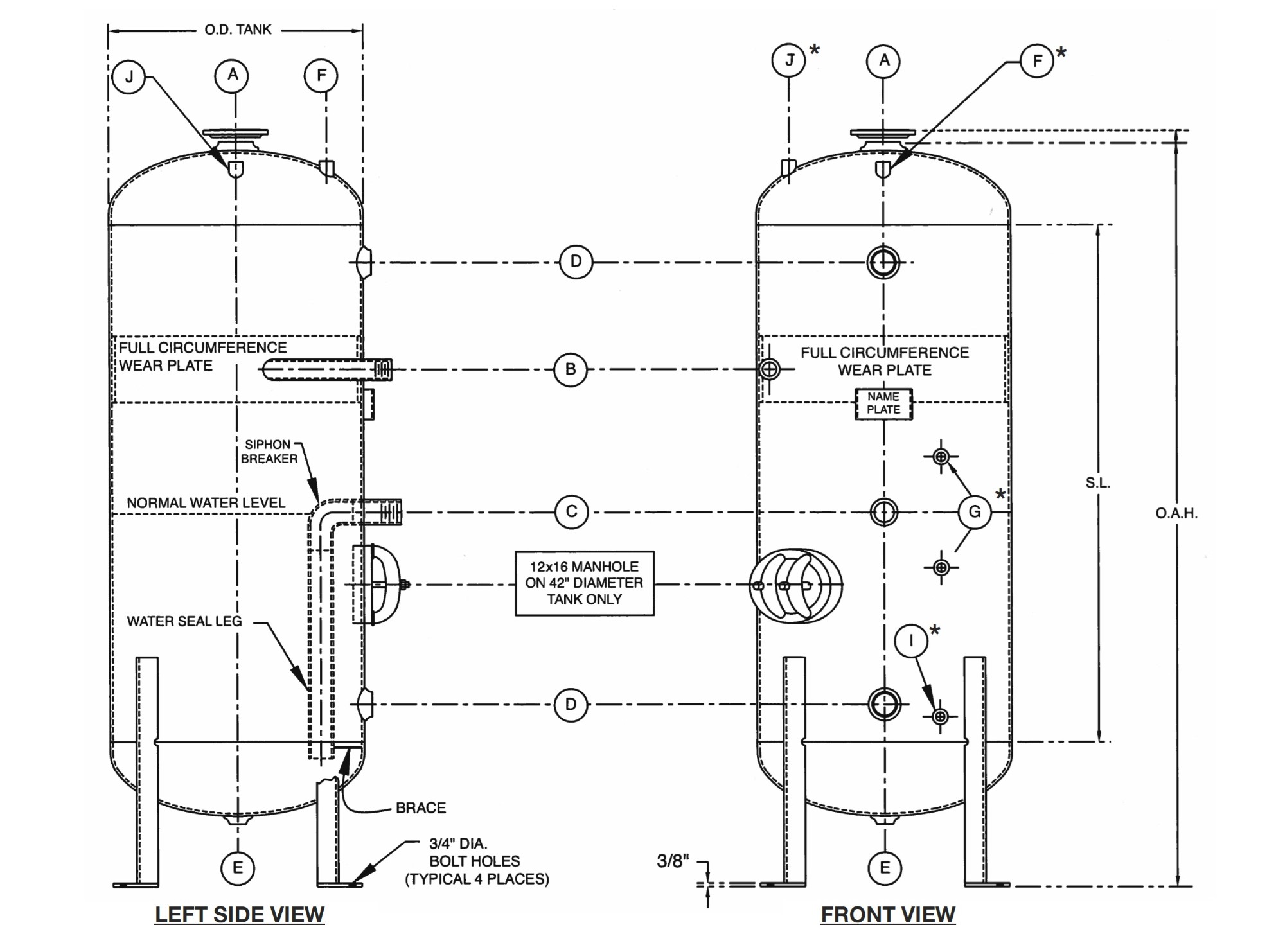

2. Blowdown Tank (High-Pressure Type)

Working Principle

-

Designed as a sealed tank with large volume.

-

Remaining water from the previous blowdown cools down and is used to cool the next discharge.

-

No continuous cold water supply is required.

Advantages

-

Safe for high-pressure operation (designed according to ASME Section VIII).

-

Independent from external cooling water.

-

Long service life and suitable for multiple boilers.

Disadvantages

-

Larger size and heavier weight.

-

Higher investment cost.

3. Comparison Between Blowdown Separator & Blowdown Tank

| Criteria | Blowdown Separator (Low Pressure) | Blowdown Tank (High Pressure) |

|---|---|---|

| Cooling method | Cold water injection | Self-cooling from stored water |

| Volume | Small | Large |

| Applicable pressure | Low – Medium | High |

| Safety level | Depends on cold water | High & stable |

| Cost | Lower | Higher |

| Application | Small plants, low discharge | Large plants, multiple boilers |

4. High-Pressure Blowdown Tank Specifications

| Model | Outside Diameter (DN) | Shell Length (mm) | Overall Height (mm) | Blowdown Volume (L) | Operating Weight (kg) | Weight with Water (kg) | Shipping Weight (kg) | Maximum Allowable Pressure (bar) |

| BDT1648 | DN400 | 1220 | 1910 | 79 | 277 | 435 | 197 | 10,3 |

| BDT1860 | DN450 | 1530 | 2240 | 136 | 404 | 540 | 268 | 10,3 |

| BDT1872 | DN450 | 1830 | 2440 | 151 | 450 | 602 | 299 | 10,3 |

| BDT2448 | DN600 | 1220 | 1980 | 204 | 528 | 733 | 324 | 10,3 |

| BDT2460 | DN600 | 1530 | 2290 | 246 | 612 | 859 | 367 | 10,3 |

| BDT2472 | DN600 | 1830 | 2490 | 288 | 699 | 983 | 411 | 10,3 |

| BDT3060 | DN750 | 1530 | 2340 | 401 | 900 | 1300 | 522 | 10,3 |

| BDT3072 | DN750 | 1830 | 2640 | 469 | 1022 | 1419 | 612 | 10,3 |

| BDT3672 | DN900 | 1830 | 2720 | 693 | 1379 | 2071 | 721 | 10,3 |

| BDT4260 | DN1050 | 1530 | 2490 | 840 | 1579 | 2419 | 748 | 10,3 |

5. Conclusion

-

For low-pressure boilers, Blowdown Separator is a cost-effective choice.

-

For high-pressure boilers, multiple boilers or maximum safety requirements, Blowdown Tank is strongly recommended.

DIVI Group, with more than 15 years of experience in manufacturing and operating industrial boilers, commits to:

-

Design compliant with ASME & TCVN standards

-

5-year warranty

-

Safe – cost-effective – environmentally compliant solutions

Hotline/Zalo: +84 942 488 818 (Mr. Hieu)

PRINCIPLE DIAGRAM

blowdown tank

blowdown tankOther Product

PCHR Steam Saving System | Save 20% Boiler Fuel Cost

While most factories are losing hundreds of thousands of dollars every year due to steam and heat loss, the PCHR Steam Saving System by DIVI delivers a breakthrough solution, helping reduce up to 20% of boiler fuel cost and achieve fast payback within 3–6 months.

EN

EN