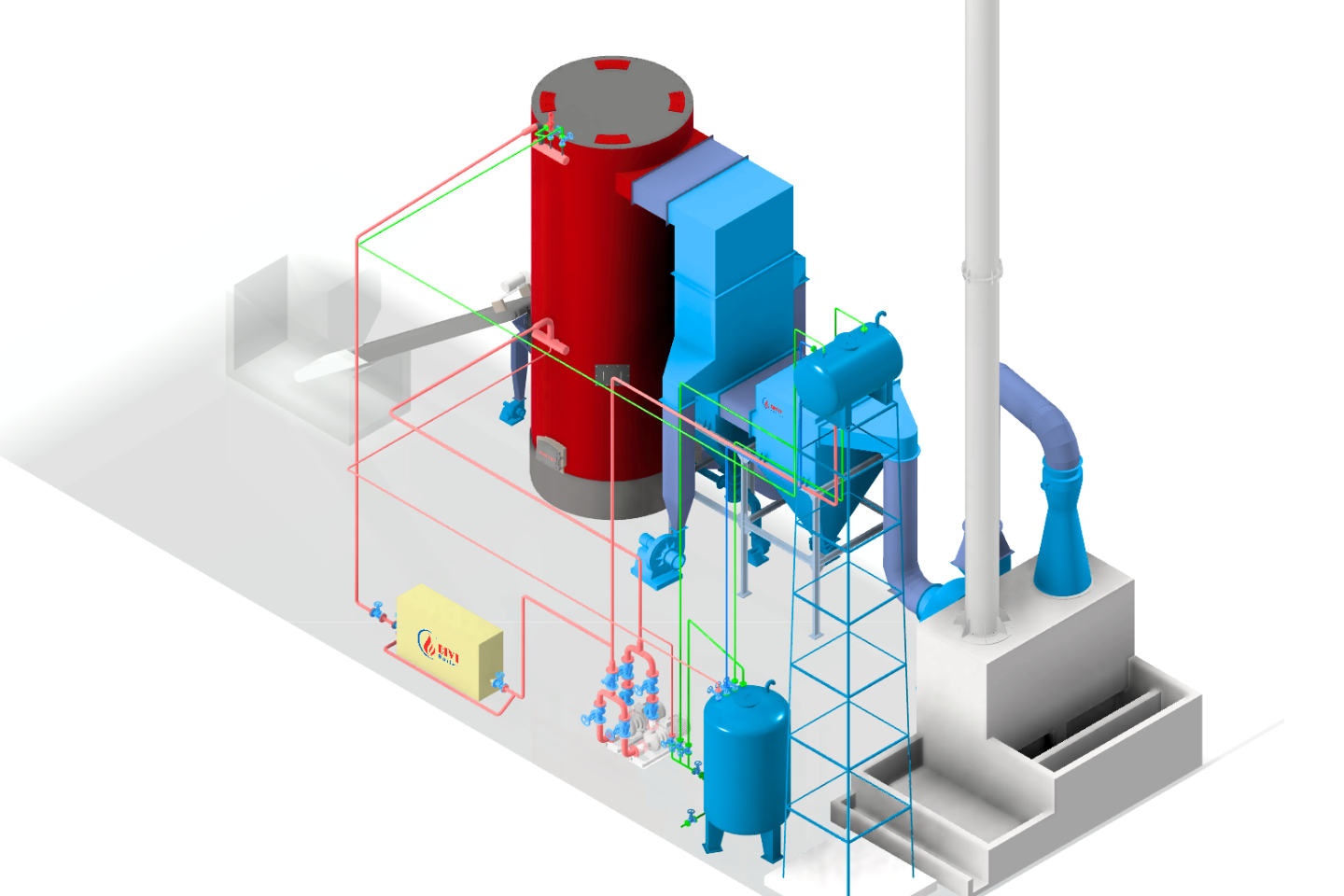

- DIVI Group's Liquid fuel-fried Boiler offer a perfect solution for businesses with strict environmental and space optimization requirements. This product is especially suitable for industries like pharmaceuticals and food, where hygiene is a top priority, as well as for businesses looking for a reliable solution without much concern for the cost of steam production.

- This technology, with its compactness and cleanliness, not only minimizes the impact on the working environment but also ensures a stable and efficient production process. DIVI Group's boilers use liquid fuel, completely eliminating dust issues, an unacceptable factor in many industries with high safety and hygiene standards.

- The complete automation system combined with the capability for remote monitoring and adjustment through advanced technology helps save on labor costs and optimize operation. The ability to quickly generate steam and maintain stability excellently meets the needs of businesses with fluctuating loads, bringing high economic efficiency in production management.

- Although it has a drawback of higher steam production costs compared to other solutions, for businesses that prioritize hygiene and operational stability, this product remains an undeniable choice. Especially with DIVI Group's commitment to quality and after-sales service, customers can be fully confident in their long-term investment without worrying about maintenance or repair costs.

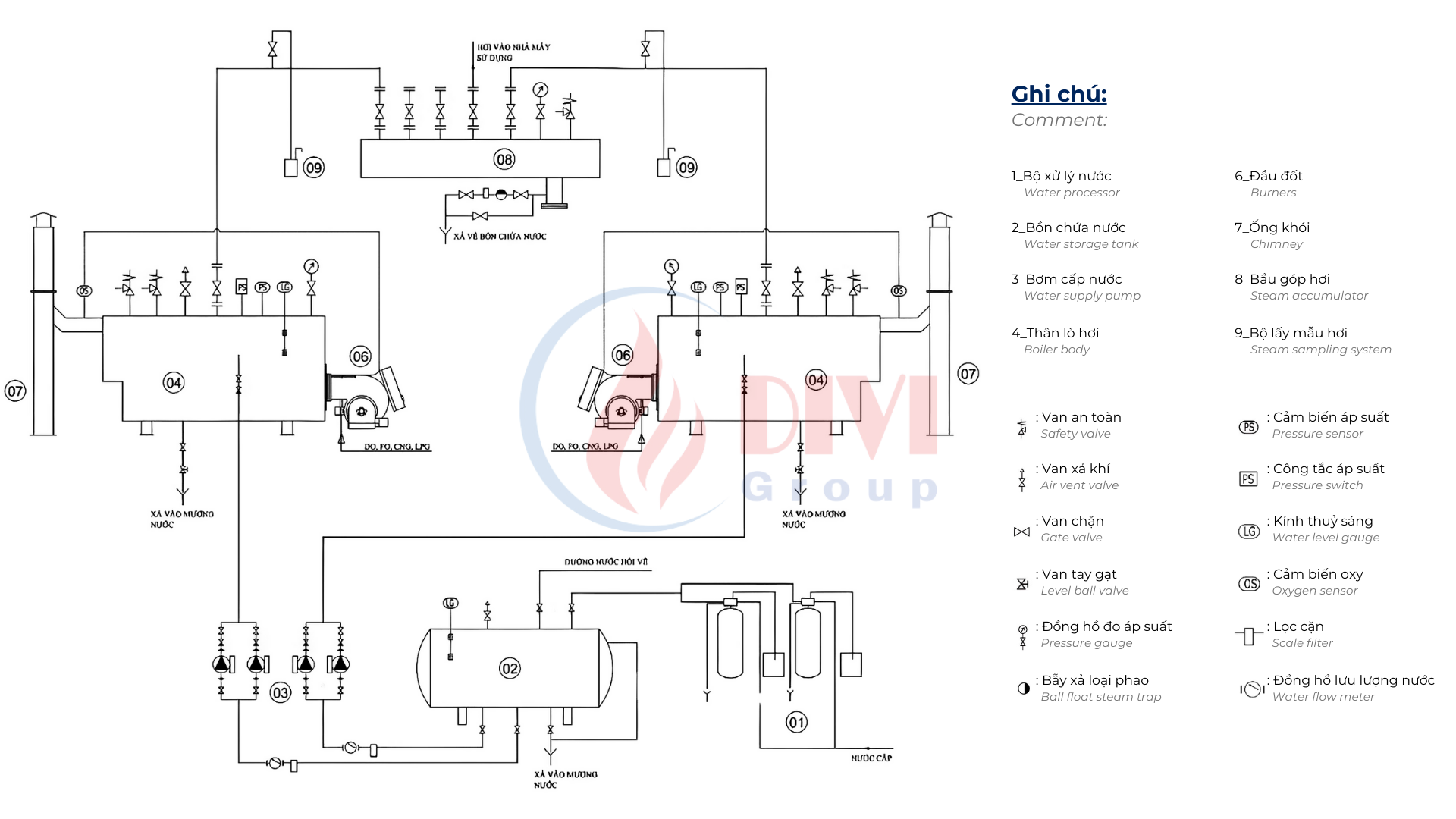

PRINCIPLE DIAGRAM

-

Basic specifications:

| Categories | Unit | Parameter | ||||||

| Design pressure | bar | 8 đến 20 | ||||||

| Saturated steam temperature | °C | 165 đến 215 | ||||||

| Boiler efficiency | % | 93 ± 2 | ||||||

| Fuel types | Diesel, Mazut, LPG, CNG | |||||||

| Fuel consumption | liter/ton of steam | Diesel | : 60 - 70 | |||||

| kg/ton of steam | LPG | : 55 - 65 | ||||||

| Sm³/ton of steam | CNG | : 65 - 79 | ||||||

| Control system | Fully automatic control using PLC – SCADA | |||||||

| Environmental standards | Ensure complete compliance with QCVN 19:2009/BTNMT | |||||||

| Boiler capacity | ton of steam/hour | 1 | 2 | 3 | 4 | 6 | 8 | 10 |

| Boiler house area | m² | 50 | 50 | 70 | 80 | 100 | 150 | 180 |

| Labor | person/shift | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Power capacity | kW | 7,5 | 13 | 18,5 | 24 | 29,5 | 35 | 40,5 |

product video

Other Product

Nồi hơi điện trở DIVI – DVG-LD

Nồi hơi đốt sinh khối compact DVG-VN

Biomass-fired fluidized bed boiler

In countries with a variety of agricultural and forestry waste products like rice husk, sawdust, cashew nut shell, chopped wood, coffee husk... with large and stable outputs like Vietnam, the choice of "Biomass-fired Fluidized Bed Boilers" is the most optimal solution, offering the highest economic efficiency among all current boiler investment options.

Biomass-fired Thermal Oil Boiler

"Biomass-fired Thermal Oil Boilers" manufactured by DIVI Group have the same advantages as the "Fluidized Bed Biomass Boilers" technology. The only difference is the medium used by the Thermal Oil Boiler is heat transfer oil, whereas the Fluidized Bed Boiler uses water vapor.

EN

EN