Compact Biomass-Fired Boiler DVG-VN – The Optimal Fossil-Fuel Replacement Solution for Factories

If your business needs to transition from fossil fuels to biomass, the compact biomass-fired boiler DVG-VN is the optimal choice thanks to its compact design, fuel savings, and compliance with new emission standards. The article below analyzes the technology, applications, and suitable fuel selections in detail.

I. Overview of Compact Biomass Combustion Technology DVG-VN

The compact biomass-fired boiler DVG-VN (pellet-fired boiler) is a new-generation product line by DIVI Group, specifically designed for small and medium enterprises requiring clean, stable steam, fuel-saving operation, and a compact system that is easy to install and maintain.

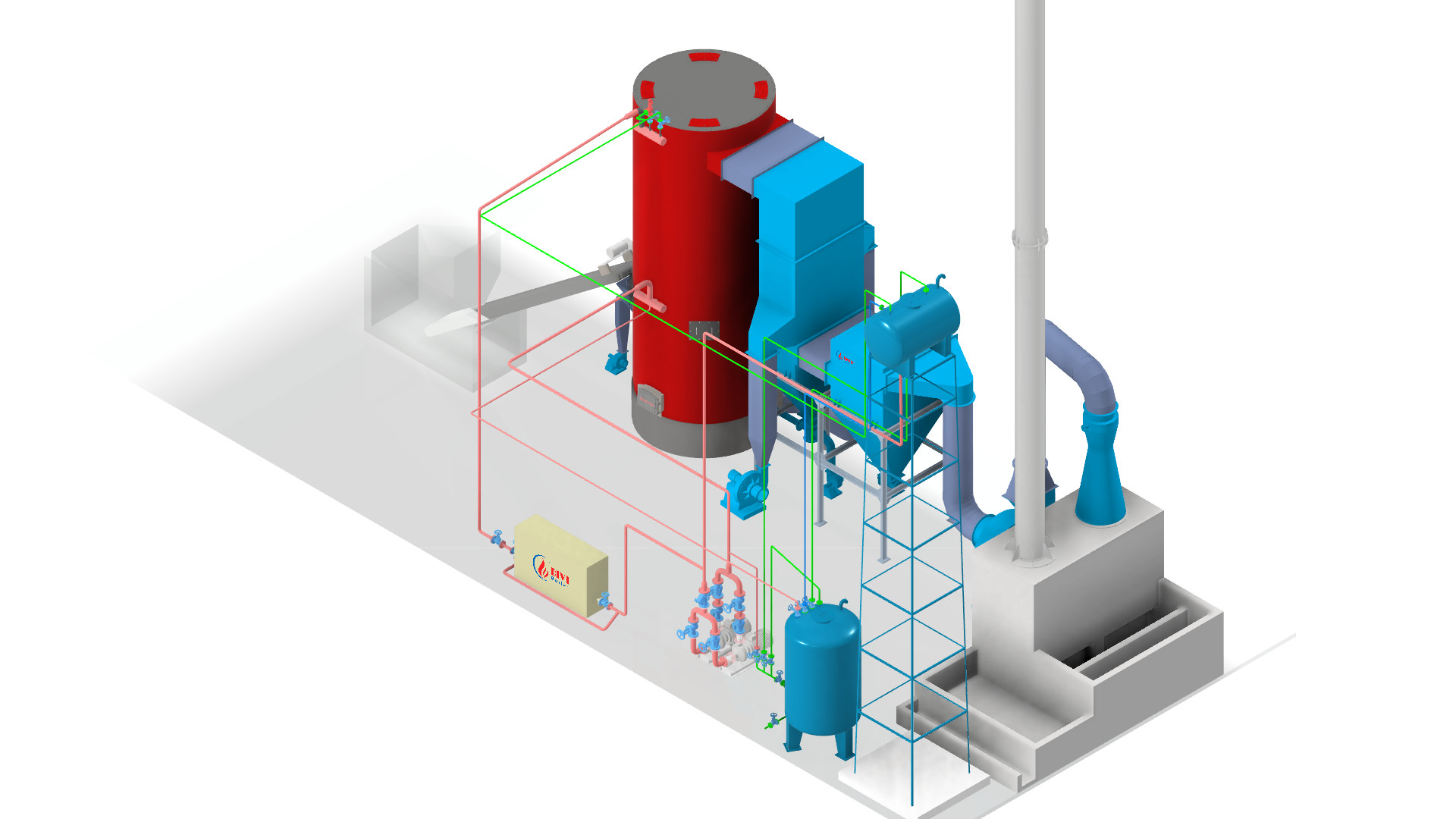

Unlike large-scale fluidized bed biomass boilers, the Compact DVG-VN version is optimized for space and integrates:

- Automatic fuel feeding system

- Flue gas treatment system

- Automated control system

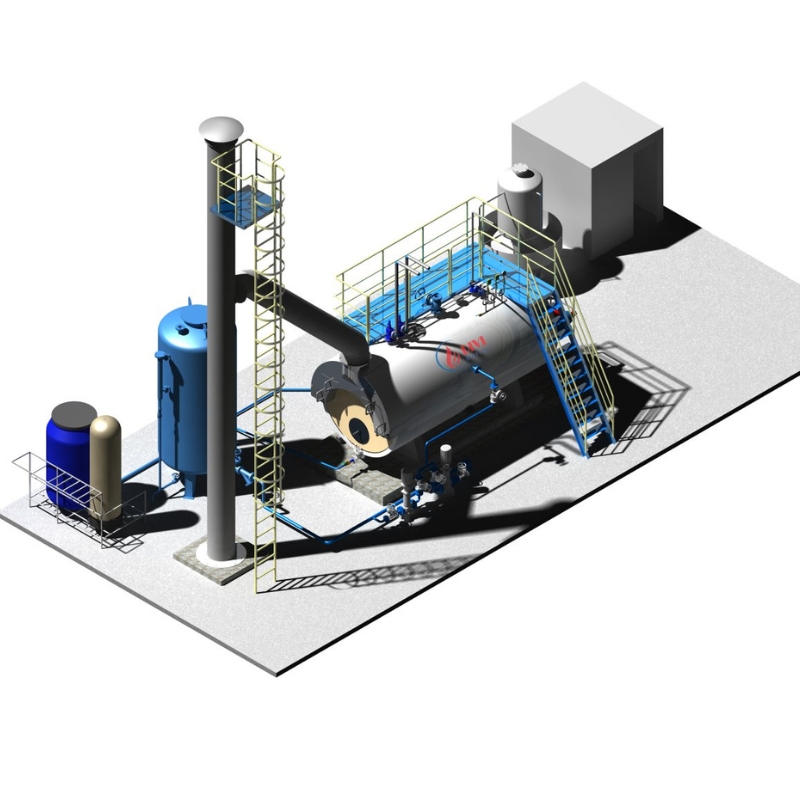

Compact Biomass-Fired Boiler

Compact Biomass-Fired BoilerII. Technical Specifications

1. Typical key specifications:

- Steam capacity: 1.0 – 5.0 tons/hour

- Efficiency: ≥ 89%

- Design pressure: 1.25 MPa

- Maximum working pressure: 1.0 MPa

- Saturated steam temperature: ≈ 184°C

2. Technical Specification Table – Compact Biomass Boiler DVG-VN

| Model | Công suất hơi (kg/h) | Hiệu suất (%) | Áp suất thiết kế (MPa) | Áp suất làm việc max (MPa) | Nhiệt độ hơi bão hòa (°C) | Tiêu hao nhiên liệu (kg/h) | Dung tích silo (kg) | Trọng lượng (kg) | Kích thước tổng thể (mm) |

|---|---|---|---|---|---|---|---|---|---|

| DVG-VN-1.0 | 1,000 | ≥ 89 | 1.25 | 1.0 | 184 | 160 | 300 | 5,300 | 3500×1800×2800 |

| DVG-VN-2.0 | 2,000 | ≥ 89 | 1.25 | 1.0 | 184 | 360 | 335 | 6,195 | 4844×1983×3082 |

| DVG-VN-3.0 | 3,000 | ≥ 89 | 1.25 | 1.0 | 184 | 480 | 400 | 9,078 | 5660×2320×3290 |

| DVG-VN-4.0 | 4,000 | ≥ 89 | 1.25 | 1.0 | 184 | 680 | 735 | 11,530 | 6220×2550×3100 |

| DVG-VN-5.0 | 5,000 | ≥ 89 | 1.25 | 1.0 | 184 | 800 | 900 | 15,800 | 6550×2260×3200 |

*Compatible With 4 Common Biomass Fuels*

To ensure operational flexibility and avoid dependence on a single fuel source, the boiler system is optimized for compatibility with multiple biomass types. This allows factories to proactively secure supply, optimize costs, and adapt to regional fuel availability.

The four most common and suitable fuels include:

- Wood pellets

- Cashew nut shell (CNS)

Palm kernel shell (PKS) - Peat briquettes

Supporting all four fuel types offers major advantages in cost, supply stability, and consistent performance. Factories can flexibly switch between biomass types depending on regional availability and fuel pricing — without modifying the boiler’s structure.

III. Benefits of Switching from Fossil Fuels to Biomass

Transitioning from coal or FO oil to biomass is becoming a clear economic and environmental solution for many factories. Thanks to abundant supply, stable pricing, and compatibility with new emission standards, biomass — especially when paired with the Compact DVG-VN boiler — offers significant advantages:

● Reduce fuel cost by 10–30%: Biomass fuels (wood pellets, cashew shells, PKS) are cheaper and more stable than coal or FO oil.

● Long-term stable supply: Vietnam has abundant agricultural and forestry by-products → continuous, proactive biomass sourcing.

● Lower emissions – compliant with new QCVN standards: Biomass reduces CO₂, NOx, SOx, and fine dust → aligned with green manufacturing trends.

● High automation – reduced labor: DVG-VN integrates automatic feeding and real-time pressure–temperature monitoring.

● Improved operational efficiency: Low moisture – complete combustion – minimal ash → efficiency ≥ 89%.

Switching to biomass not only lowers cost but also enhances clean and safe operation standards. When combined with the DVG-VN compact boiler, efficiency is maximized, manpower is reduced, and steam quality becomes more stable. This is a strategic shift for long-term profitability and environmental compliance.

IV. Industry Applications – Operator’s Perspective

- Wood & Paper Processing Industry: Factories producing timber, MDF, plywood, and paper require large, stable steam volumes. Pellet-fired boilers are preferred for their high calorific value, low moisture, and clean combustion, reducing fouling and minimizing maintenance. This ensures continuous production and consistent product quality.

- Food & Beverage Industry: In food production (noodles, seafood, beverages, noodles, bakery, etc.), steam is used for drying, steaming, cooking, sterilizing, and pasteurizing. Biomass boilers offer stable heat, long-term operation, and lower fuel costs compared to FO oil or coal. They also produce less smoke/dust, supporting hygiene and food safety requirements.

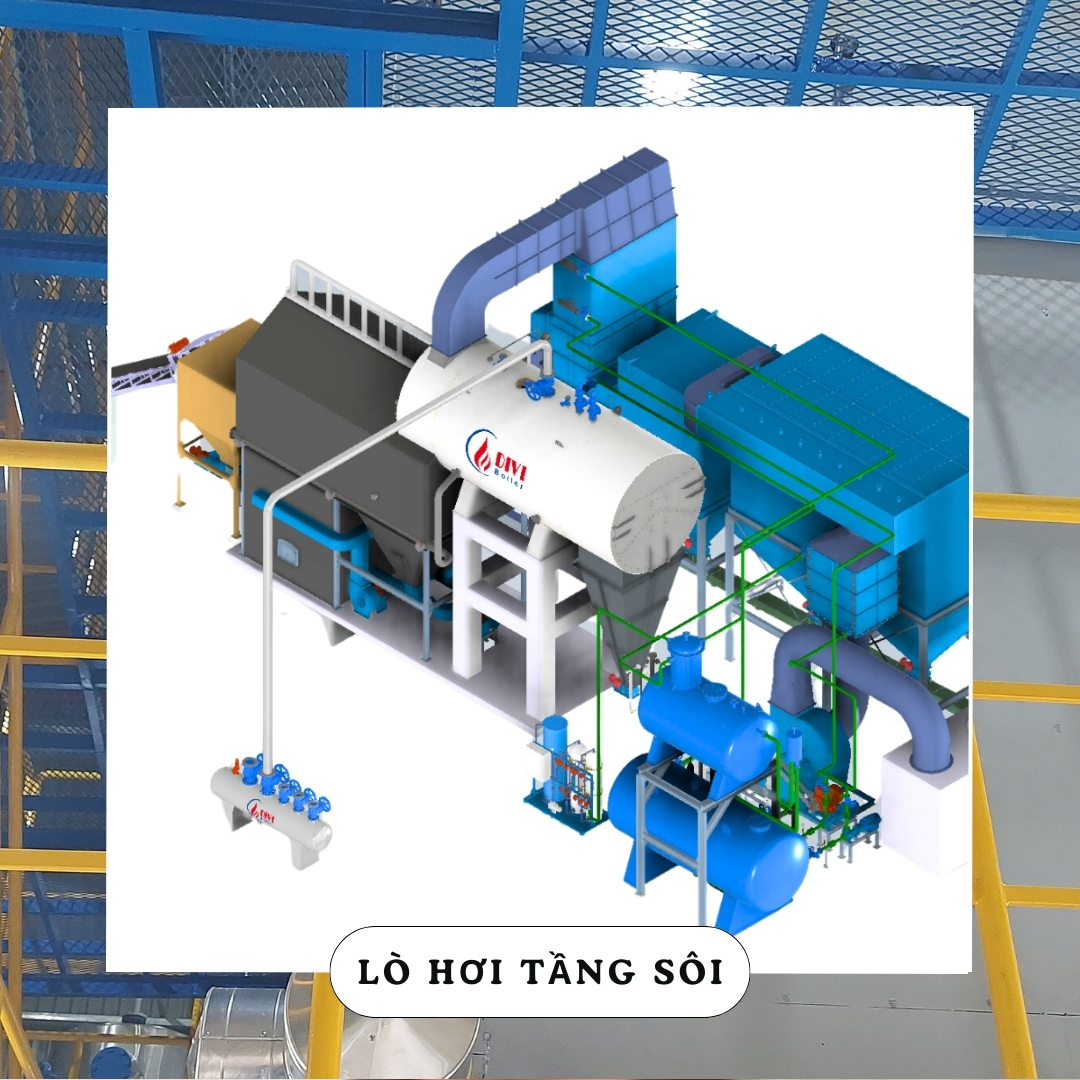

- Biomass Power Plants: Many power plants across Vietnam and Southeast Asia use CFBC biomass boilers to burn biomass for electricity. CFBC technology supports multiple fuels (sawdust, rice husk, cashew shell), offers high combustion efficiency, and meets emission control requirements.

- Factories With Agricultural By-products: Cashew processors, agricultural factories, and animal-feed producers generate large volumes of cashew shells, rice husk, sawdust, and bagasse — ideal biomass fuels. Using internal by-products cuts steam cost and reduces waste disposal requirements.

V. Biomass Fuel Comparison: Wood Pellet – PKS – CNS – Peat Briquette

| Fuel Type | Heating Value | Moisture | Ash | Key Advantages | Suitable For |

|---|---|---|---|---|---|

| Wood Pellet | High & stable | 6–10% | Very low | Clean burning, high efficiency | All industries |

| PKS | High | 12–18% | Low | Low cost | Areas with PKS supply |

| CNS | Medium | 8–14% | Low | Abundant in Vietnam | Cashew & wood factories |

| Peat Briquette | Medium | 10–20% | Medium | Easy to pelletize | Central Highlands |

Biomass fuel comparison for pellet fired boilers

Biomass fuel comparison for pellet fired boilers

Fuel selection summary:

- Wood pellet → best for efficiency

- PKS / CNS → best for cost optimization

- Peat briquette → best for regions with local supply

VI. Conclusion

The compact biomass-fired boiler DVG-VN is the ideal choice for businesses transitioning away from fossil fuels toward a cleaner, more stable operating model. Its compact design, high automation, and ability to burn multiple biomass types — wood pellets, PKS, CNS, peat briquettes — help optimize cost and meet environmental standards.

The system delivers safe operation, clean steam, low ash, and minimal maintenance, becoming a sustainable solution for factories aiming for long-term green and efficient production.

Contact DIVI Group today to receive tailored configuration advice and a detailed quotation for your biomass boiler system.

Related Articles:

Additional Reference Videos:

[DIVI] Reveal interesting things from steam boilers from the steam room for newcomerse

[DIVI] Boiler safety and practices for safe operation

DIVI Group's Boiler Products:

Other news

-

Steam Separator – An Effective Solution for Dry Steam

29/12/2025, -

Treating High CO Emissions in Fixed-Grate Boilers – Is Boiler Replacement Necessary? Practical Solutions from DIVI

18/12/2025, -

What Is a Steam Trap? Principles, Types, and How to Select the Right Steam Trap for Your Steam System

07/12/2025, -

COMPARISON OF STEAM TRAPS: PRINCIPLES – EXPERIMENTS – OPTIMAL SELECTION FOR STEAM SYSTEMS

29/11/2025, -

Which Boiler Should You Choose: Fixed Grate or Fluidized Bed? Detailed Efficiency, Cost & Environmental Comparison

24/06/2025, -

5 Common Mistakes in Industrial Steam Distribution Systems

11/06/2025, -

Mr. Boiler Speaks: Wake-Up Call from an Industrial Icon

09/06/2025, -

What is a Thermal Oil Heater? Structure, Benefits & Safety Tips

27/05/2025, -

3 Danger Signs of Boiler Operation You Should Never Ignore

24/05/2025, -

7 Common Causes of Boiler Flue Gas Issues – Effective Treatment Solutions

08/05/2025,

EN

EN