Why Choose Oil & Gas-Fired Steam Boilers?

1. High Efficiency – Lower Fuel Consumption

With advanced combustion design, these boilers achieve up to 90% thermal efficiency. Heat exchange systems are optimized to minimize energy loss, helping businesses cut fuel costs significantly.

2. Wide Range of Industrial Applications

-

Food, textiles, chemicals: Provides steam for production processes

-

Hospitals, hotels: Supplies hot water and steam for sterilization

-

Power plants, wood factories: Uses high-pressure steam to run machinery

3. Smart Control System – High Automation

Equipped with PLC–SCADA control systems, these boilers offer full remote monitoring and automatic adjustments to pressure and temperature. Stable operation with minimal manual input.

4. Durability & Easy Maintenance

Made with high-quality, heat-resistant materials, the boilers have long service life. The self-cleaning system reduces scale build-up, making maintenance simpler.

Economic Benefits of Oil & Gas-Fired Boilers

- Lower fuel costs: Gas and oil are often cheaper to operate than coal or electricity

- Improved productivity: Quick steam generation meets production demand promptly

- Reduced labor costs: Automation reduces staffing needs

- Environmentally friendly: Clean combustion process minimizes harmful emissions

Which Boiler Should You Choose?

-

Oil-fired boilers: Best for businesses with high-capacity needs and continuous operation

-

Gas-fired boilers: Ideal for fuel savings and eco-friendly operations

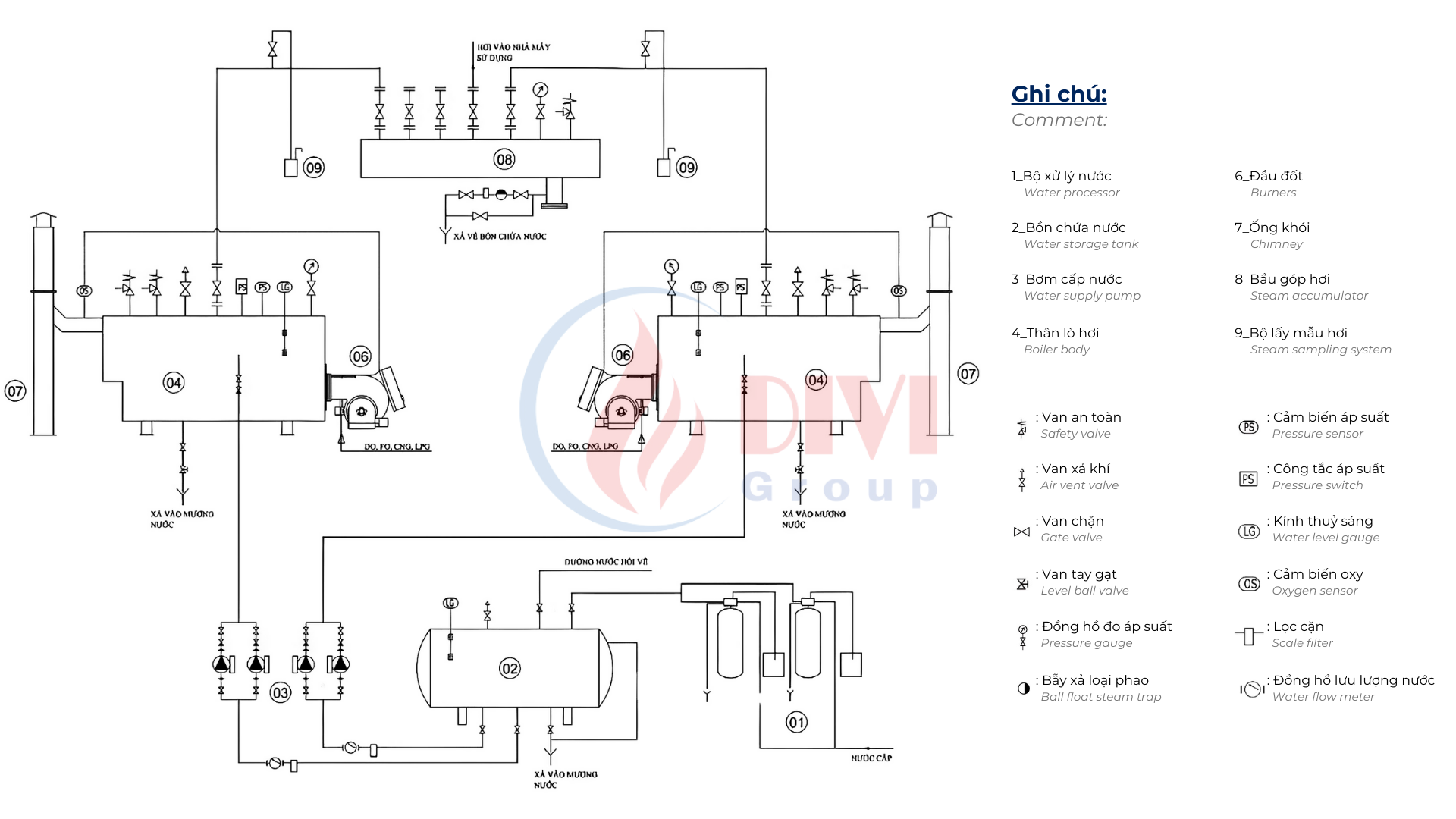

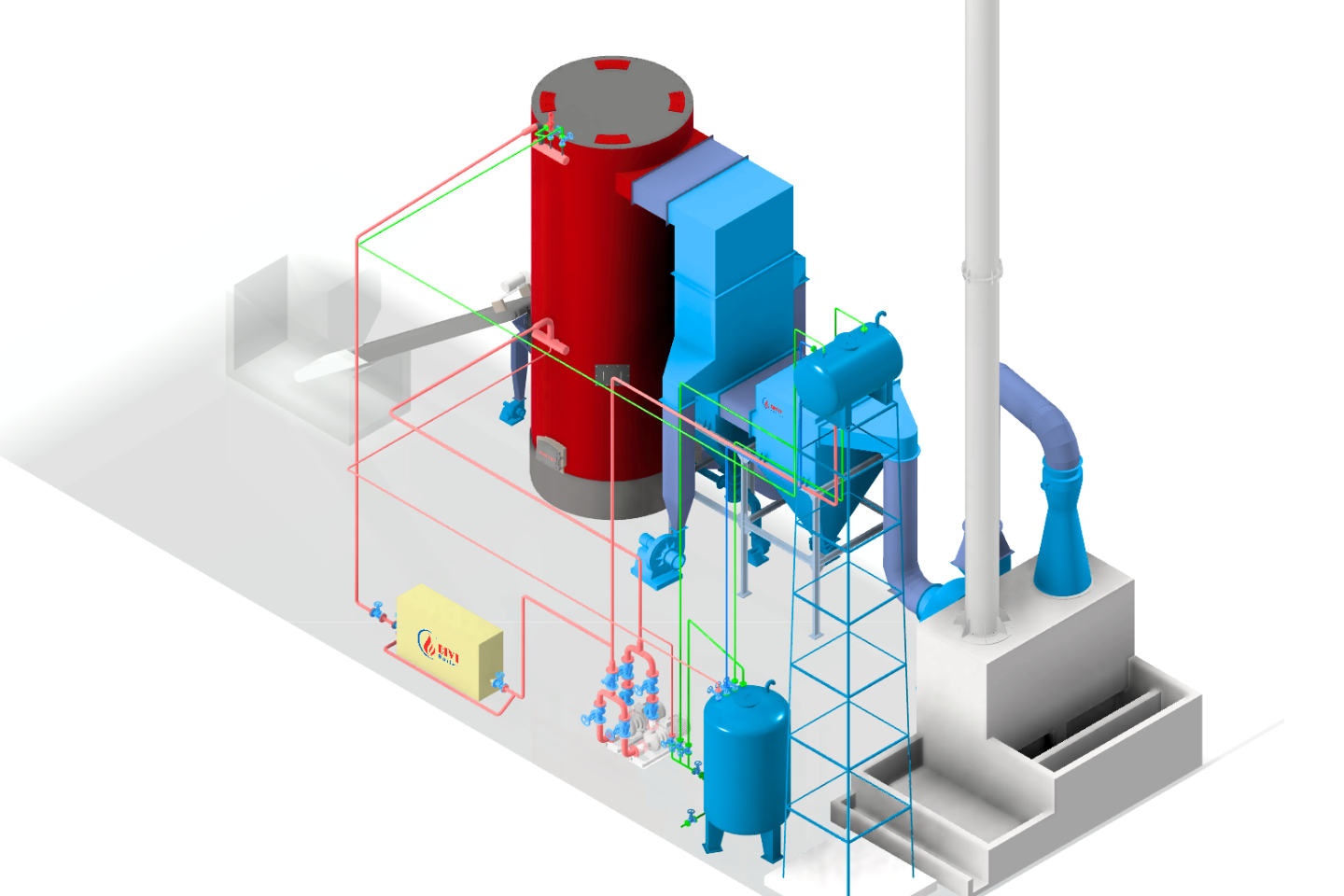

PRINCIPLE DIAGRAM

-

Basic specifications:

| Categories | Unit | Parameter | ||||||

| Design pressure | bar | 8 đến 20 | ||||||

| Saturated steam temperature | °C | 165 đến 215 | ||||||

| Boiler efficiency | % | 93 ± 2 | ||||||

| Fuel types | Diesel, Mazut, LPG, CNG | |||||||

| Fuel consumption | liter/ton of steam | Diesel | : 60 - 70 | |||||

| kg/ton of steam | LPG | : 55 - 65 | ||||||

| Sm³/ton of steam | CNG | : 65 - 79 | ||||||

| Control system | Fully automatic control using PLC – SCADA | |||||||

| Environmental standards | Ensure complete compliance with QCVN 19:2009/BTNMT | |||||||

| Boiler capacity | ton of steam/hour | 1 | 2 | 3 | 4 | 6 | 8 | 10 |

| Boiler house area | m² | 50 | 50 | 70 | 80 | 100 | 150 | 180 |

| Labor | person/shift | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Power capacity | kW | 7,5 | 13 | 18,5 | 24 | 29,5 | 35 | 40,5 |

product video

Other Product

Electric Resistance Steam Boiler DIVI DVG-LD

Compact Biomass Boiler DIVI DVG-VN

The DVG-VN Compact Biomass Steam Boiler – a space-efficient industrial steam solution delivering up to 92% thermal efficiency.

Engineered for versatile fuel compatibility, it operates effectively with wood pellets, cashew shell pellets, palm kernel shells, and peat briquettes.

Designed for economical operation, safety, and environmental sustainability, the DVG-VN series is manufactured by DIVI Group Vietnam to meet modern industrial steam demands with reliability and outstanding energy performance.

Biomass-fired fluidized bed boiler

In countries with a variety of agricultural and forestry waste products like rice husk, sawdust, cashew nut shell, chopped wood, coffee husk... with large and stable outputs like Vietnam, the choice of "Biomass-fired Fluidized Bed Boilers" is the most optimal solution, offering the highest economic efficiency among all current boiler investment options.

Biomass-fired Thermal Oil Boiler

Biomass-fired Thermal Oil Boilers" manufactured by DIVI Group have the same advantages as the "Fluidized Bed Biomass Boilers" technology. The only difference is the medium used by the Thermal Oil Boiler is heat transfer oil, whereas the Fluidized Bed Boiler uses water vapor.

EN

EN