Have You Ever Wondered: How Can Your Business Both Save Costs and Contribute to the Environment?

I used to wonder the same thing—until I discovered biomass-fired thermal oil heaters. This is one of the most advanced technologies that helps businesses optimize fuel costs and maximize operational efficiency.

The most fascinating aspect is that it utilizes biomass fuel derived from agricultural by-products—materials we often consider worthless—such as rice husks, sawdust, and coffee husks. Yet, these seemingly discarded materials have become a sustainable and economical solution for the industrial sector.

Why Biomass-Fired Thermal Oil Heaters Are the Optimal Choice

1. Outstanding Efficiency at Low Cost

Biomass-fired thermal oil heaters offer an efficiency rate of up to 85%. Thanks to advanced biomass combustion technology, the system consumes less fuel while still meeting the high thermal demands in industries such as textile dyeing, wood processing, and food manufacturing.

2. Fast and Stable Heat Generation

DIVI Group’s thermal oil heaters are capable of rapid heat generation and maintaining stable temperature output. This is especially important in industries requiring continuous heating. The system is designed with multiple levels of heat recovery, minimizing thermal losses to the greatest extent.

3. Advanced Automated Control Technology

Equipped with a PLC-SCADA automatic control system, users can easily monitor and adjust operations remotely while minimizing the number of operators. Only 2 workers per shift are needed, significantly reducing labor costs and increasing precision in the production process.

Biomass Combustion Technology vs. Traditional Methods

1. What Is Biomass Fuel?

Biomass fuel includes agricultural residues like rice husks, sawdust, and coffee husks—renewable resources that are abundant and readily available in Vietnam. By using these instead of oil or coal, businesses not only reduce costs but also lower emissions into the environment.

2. Key Differences Between Thermal Oil Heaters and Boilers

Unlike boilers that use water to generate steam, thermal oil heaters use heat transfer oil, ensuring more stable thermal transmission. This increases safety, lowers maintenance costs, and allows for more precise temperature control throughout the production process.

3. Applications of Biomass-Fired Thermal Oil Heaters

-

Textile and Dyeing Industry: Requires stable temperatures to maintain product quality.

-

Wood Processing Industry: Especially crucial in drying and heating processes.

-

Food and Beverage Industry: Ensures hygiene and safety standards during production.

-

Rubber Industry: Requires high heat energy for processing and manufacturing rubber products.

Economic and Environmental Impact

1. Fuel Savings and Reduced Operating Costs

Using biomass fuel significantly cuts operating costs since it is much cheaper than oil or coal. Especially in Vietnam, businesses can take advantage of locally available agricultural residues, reducing dependency on imported fuels and stabilizing production costs.

2. Emissions Reduction and Environmental Protection

Biomass-fired thermal oil heaters help reduce CO₂ emissions, contributing to environmental protection and meeting strict environmental standards.

DIVI Group – Commitment to Quality and Support

DIVI Group is committed to delivering the most advanced thermal oil heater solutions to Vietnam’s industrial sector. With a warranty of up to 36 months for the main body of the heater, along with continuous technical support and monitoring for 3 years, we ensure complete satisfaction for our clients.

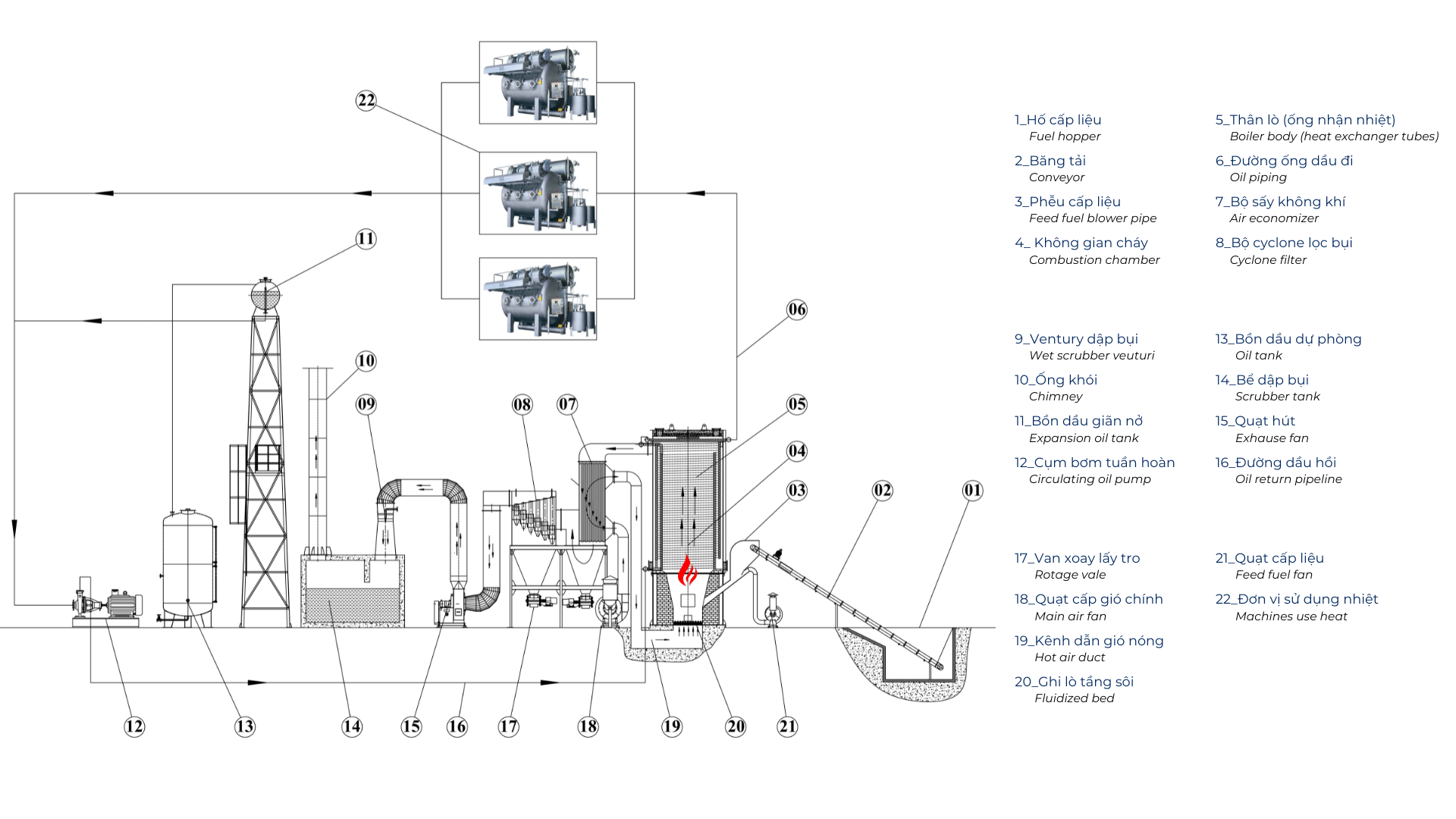

PRINCIPLE DIAGRAM

-

Basic specifications:

| Categories | Unit | Parameter | ||||||

| Design pressure | bar | 10 | ||||||

| Saturated steam temperature | °C | 300 | ||||||

| Boiler efficiency | % | 85 ± 2 | ||||||

| Fuel types | Rice husk, wood chips, cashew nut shells, sawdust, coffee husk and other types of biomass | |||||||

| Fuel consumption | kg/million kCal | Wood chips | : 450 - 675 | |||||

| kg/million kCal | Rice husk | : 255 - 375 | ||||||

| kg/million kCal | Cashew nut shells | : 255 - 338 | ||||||

| Control system | Fully automatic control using PLC – SCADA | |||||||

| Environmental standards | Ensure complete compliance with QCVN 19:2009/BTNMT | |||||||

| Boiler capacity | million kCal/hour | 1 | 2 | 3 | 4 | 6 | 8 | 10 |

| kWh | 1.163 | 2.326 | 3.489 | 4.652 | 6.978 | 9.304 | 11.630 | |

| Boiler house area | m² | 250 | 250 | 420 | 500 | 600 | 720 | 8500 |

| Labor | person/shift | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| Power capacity | kW | 60 | 100 | 120 | 160 | 240 | 300 | 350 |

product video

Other Product

Electric Resistance Steam Boiler DIVI DVG-LD

Compact Biomass Boiler DIVI DVG-VN

The DVG-VN Compact Biomass Steam Boiler – a space-efficient industrial steam solution delivering up to 92% thermal efficiency.

Engineered for versatile fuel compatibility, it operates effectively with wood pellets, cashew shell pellets, palm kernel shells, and peat briquettes.

Designed for economical operation, safety, and environmental sustainability, the DVG-VN series is manufactured by DIVI Group Vietnam to meet modern industrial steam demands with reliability and outstanding energy performance.

Biomass-fired fluidized bed boiler

In countries with a variety of agricultural and forestry waste products like rice husk, sawdust, cashew nut shell, chopped wood, coffee husk... with large and stable outputs like Vietnam, the choice of "Biomass-fired Fluidized Bed Boilers" is the most optimal solution, offering the highest economic efficiency among all current boiler investment options.

Oil-Fired & Gas-Fired Steam Boiler

Are you looking for an oil-fired or gas-fired steam boiler that helps save fuel while ensuring high performance? With advanced combustion technology, this is an ideal solution for various industries — optimizing operating costs while meeting strict production demands.

EN

EN