Mr. Boiler Speaks: Wake-Up Call from an Industrial Icon

When an industrial equipment speaks, will you listen?

In the video “If Boilers Could Speak,” Mr. Boiler — a 200-year-old symbol of factory operations — breaks his long silence to reveal the hidden dangers, explosions, and critical mistakes that have been overlooked for decades. This is a powerful new perspective on the role of industrial equipment in the modern manufacturing era.

Who Is Mr. Boiler?

Mr. Boiler – The Core Industrial Equipment in Modern Manufacturing Plants

Mr. Boiler – The Core Industrial Equipment in Modern Manufacturing PlantsHe is not an engineer, nor a technical expert. But for over 200 years, he has operated silently in millions of factories worldwide — in the form of high-pressure, high-temperature industrial equipment known as a boiler.

Since the earliest days of the mechanization revolution, Mr. Boiler has been the driving force behind key industries such as food processing, rubber, paper, textiles, and even renewable energy — where steam remains the core energy medium in production lines.

"I was once treated like a precious asset in modern power plants — every pressure valve monitored with sensors. But I’ve also been neglected in small workshops, where I’m seen as nothing more than an oversized kettle — no need to understand me, no need for maintenance."

Today, as industry enters the era of Industry 4.0, industrial equipment like Mr. Boiler is no longer just about being connected, automated, or IoT-integrated. It must be managed like a living entity — playing a central role in the production ecosystem.

Industrial Equipment Deserves to Be Properly Understood

1. Even Industrial Equipment Needs Understanding

Boiler blowdown must be performed regularly

Boiler blowdown must be performed regularlyMany businesses — especially small and medium-sized enterprises — still underestimate the importance of foundational industrial equipment. But as Mr. Boiler has shown, even a minor mistake in operation or maintenance can lead to serious consequences:

-

Untreated feedwater causes internal corrosion and reduces equipment lifespan.

-

Failure to perform scheduled blowdown allows scale and sludge buildup, decreasing heat transfer efficiency.

-

Lack of routine maintenance leads to equipment degradation, increasing the risk of unexpected breakdowns.

-

Improper operation significantly raises the chances of industrial equipment explosions and production downtime.

2. Industrial Equipment Is Often Overlooked in Operational Strategy

The problem isn’t just untrained operators — it lies in fragmented thinking around system design, management, and training.

Most industrial equipment operates under extreme conditions: high pressure, elevated temperatures, and nonstop production intensity. Yet many businesses fail to integrate proper safety and maintenance into their operational strategies, including:

-

No dedicated equipment maintenance team

-

No structured training program for boiler engineers

-

No formal incident response procedures

As a result, steam systems and pressure equipment become silent risks — increasing the chances of production downtime, equipment failure, or even catastrophic accidents.

3. The Consequences of Ignoring Industrial Equipment

Some places gave me untreated pond water to ‘drink’ for years. When I got weaker, they blamed the fuel. When I finally exploded, they asked: Why didn’t you warn us earlier?

A forgotten industrial equipment is not a broken machine. It is a ticking time bomb — a hidden industrial hazard quietly building up. Without routine inspection, preventive maintenance, and clear management protocols, it will eventually lead to system breakdowns, financial losses, or human tragedy.

Industrial Equipment Deserves Strategic Attention

1. Don’t Treat Industrial Equipment as Secondary

In manufacturing systems, many businesses focus solely on machines like presses, packaging lines, or conveyors — while ignoring foundational industrial equipment, especially steam-generating systems. Yet without this equipment, the entire production line grinds to a halt.

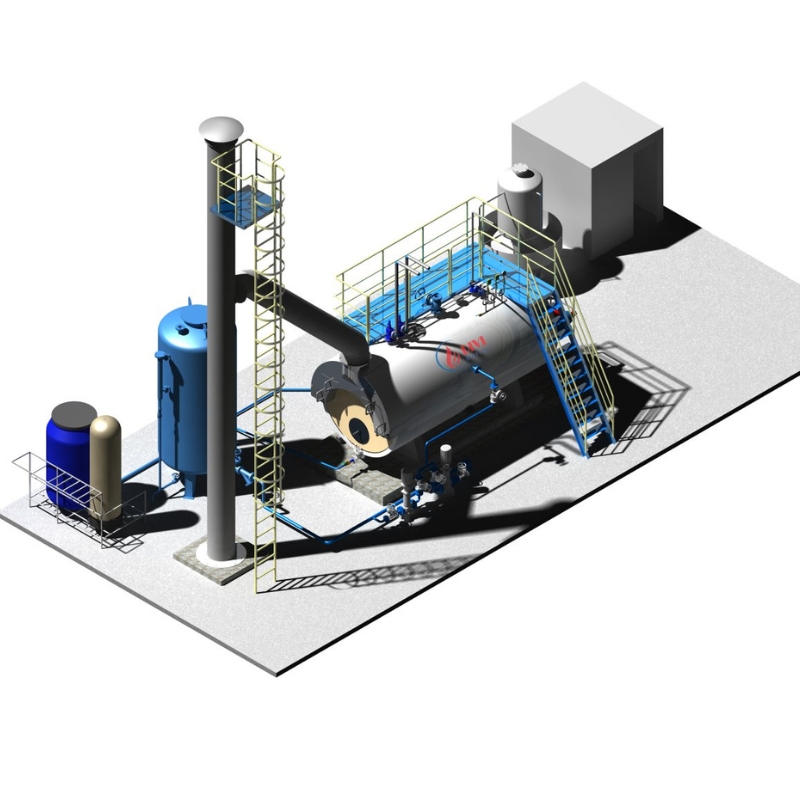

2. Water Treatment – Blowdown – Scheduled Maintenance

Boiler water treatment system for industrial equipment

Boiler water treatment system for industrial equipment

In steam-based industrial equipment like boilers, heat exchangers, and thermal pipelines, three core factors determine longevity and operational stability:

-

Proper feedwater treatment prevents internal corrosion and scale buildup.

-

Routine blowdown eliminates sludge and sediments, extending equipment life.

-

Scheduled maintenance detects early failures and avoids costly repairs.

Though often overlooked, these three actions are the foundation for safe and efficient boiler operation. They help optimize fuel usage, minimize downtime, and maintain stable production output over the long term.

3. Hire the Right People – or Train Them Properly

DIVI doesn’t just manufacture equipment — we provide operational solutions. Don’t hesitate to hire someone who knows me better than you.

If your business lacks an in-house technical team with sufficient expertise, outsourcing to a professional operation partner like DIVI is a smart move.

This approach not only boosts system efficiency but also reduces operational risks, maintenance costs, and allows your team to focus on core product development.

Rethinking Industrial Equipment – Operate Smarter, Not Just Harder

The video “If Boilers Could Speak” is not merely a technical conversation — it’s a wake-up call about misconceptions in modern plant operations.

-

Industrial equipment deserves the same respect as your workforce or materials.

-

Proper operation begins with strategic thinking, not just technical instructions.

-

View equipment as a true member of your production team — with roles, limitations, and the need for regular care.

Conclusion – Don’t Let Equipment “Speak” Through Failure

Mr. Boiler is not just a symbolic figure for steam boilers. He represents all the overlooked industrial equipment quietly working behind the scenes in today’s factories.

These machines are silent, consistent, and reliable. But when ignored, they won’t speak with words — they’ll speak through failures: downtime, explosions, injuries, and lost assets.

Act before it’s too late.

Contact DIVI today for expert guidance on safe, efficient, and cost-effective industrial equipment operation.

Related Articles:

Additional Reference Videos:

3 Signs Your Boiler Is Underperforming – And You Don’t Even Know It!

5 Easy Ways to Reduce Fuel Consumption in Your Boiler System

DIVI Group's Boiler Products:

Other news

-

Steam Separator – An Effective Solution for Dry Steam

29/12/2025, -

Treating High CO Emissions in Fixed-Grate Boilers – Is Boiler Replacement Necessary? Practical Solutions from DIVI

18/12/2025, -

What Is a Steam Trap? Principles, Types, and How to Select the Right Steam Trap for Your Steam System

07/12/2025, -

COMPARISON OF STEAM TRAPS: PRINCIPLES – EXPERIMENTS – OPTIMAL SELECTION FOR STEAM SYSTEMS

29/11/2025, -

Compact Biomass-Fired Boiler DVG-VN – The Optimal Fossil-Fuel Replacement Solution for Factories

23/11/2025, -

Which Boiler Should You Choose: Fixed Grate or Fluidized Bed? Detailed Efficiency, Cost & Environmental Comparison

24/06/2025, -

5 Common Mistakes in Industrial Steam Distribution Systems

11/06/2025, -

What is a Thermal Oil Heater? Structure, Benefits & Safety Tips

27/05/2025, -

3 Danger Signs of Boiler Operation You Should Never Ignore

24/05/2025, -

7 Common Causes of Boiler Flue Gas Issues – Effective Treatment Solutions

08/05/2025,

EN

EN