What Is a Fluidized Bed Boiler? Principles, Benefits, and Industrial Applications

What makes a fluidized bed boiler a smarter choice over conventional steam generation systems? If you are in search of an energy-efficient, low-emission, and fuel-flexible solution, understanding the principles and advantages of fluidized bed combustion boilers is critical. In this article, we’ll explore everything you need to know about this innovative technology.

Fluidized bed boilers represent an advanced combustion technology that maximizes fuel efficiency, reduces environmental impact, and optimizes overall energy performance. By leveraging the principles of fluidized bed combustion, these systems ensure complete fuel burn, helping businesses cut operating costs and enhance long-term sustainability.

What is a fluidized bed boiler?

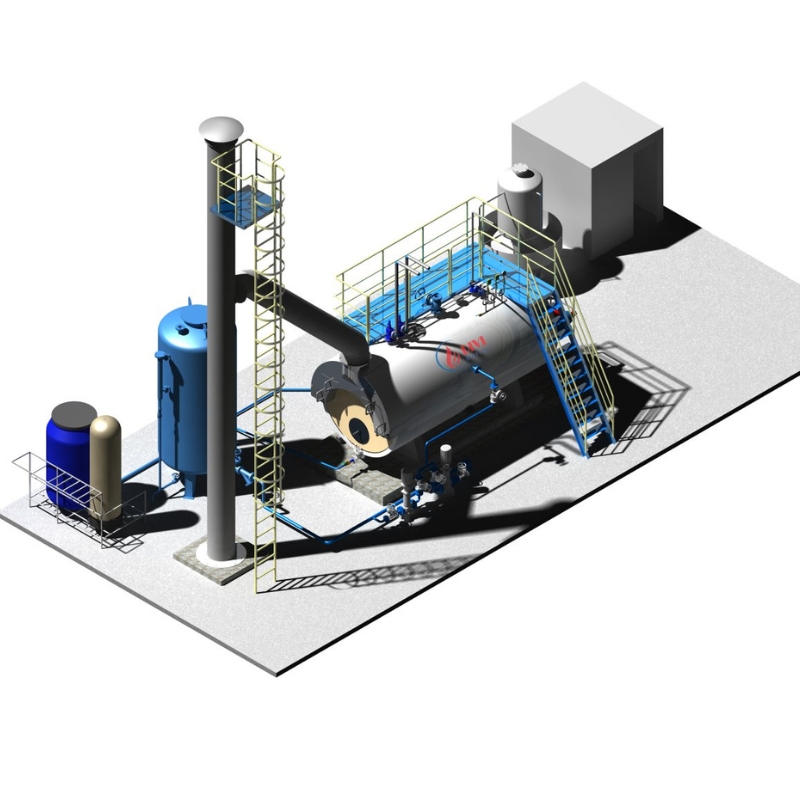

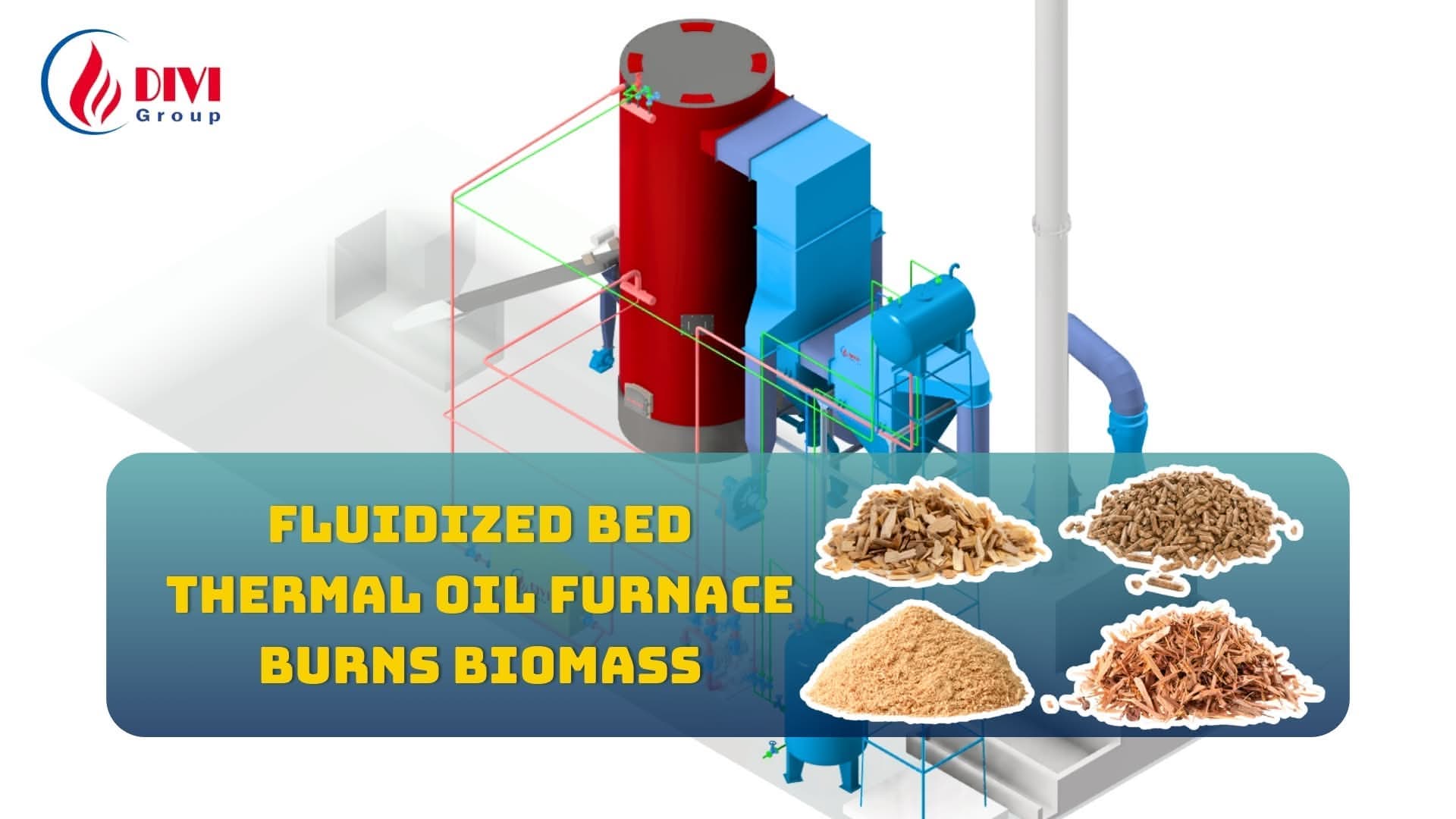

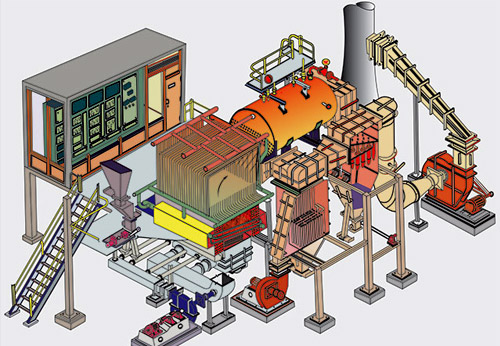

Fluidized bed boiler of DIVI GROUP

Fluidized bed boiler of DIVI GROUPA fluidized bed boiler is an advanced type of industrial steam generator that utilizes a fluidized bed combustion process. In this system, solid fuel particles are suspended in a turbulent, bubbling bed of inert materials such as sand, ash, or limestone. This phenomenon, called fluidization, significantly enhances the fuel-air mixing process, resulting in more complete combustion, higher efficiency, and lower emissions.

Key Characteristics:

-

Utilizes fluidized bed combustion (FBC) technology, where fuel burns while suspended in a fluid-like medium.

-

Compatible with various fuels, including coal, biomass, waste materials, and refuse-derived fuels.

-

Operates at relatively low combustion temperatures (~850°C), minimizing the formation of nitrogen oxides (NOx).

-

Typically categorized into two types: bubbling fluidized bed (BFB) and circulating fluidized bed boiler (CFB) systems.

This unique design allows the fluidized bed combustion boiler to offer exceptional thermal efficiency, flexible fuel handling, and compliance with modern environmental standards.

Origin and evolution of fluidized bed boiler technology

The technology behind fluidized bed boilers was initially developed in the late 1960s in industrialized nations such as Germany, Sweden, and the United Kingdom. The original goal was to build a combustion system capable of utilizing low-grade, inexpensive solid fuels like lignite, peat, and agricultural waste, while significantly reducing toxic emissions like NOx and SOx—major pollutants in conventional boilers.

By the 1980s and 1990s, this breakthrough evolved into widespread adoption across high-energy-demand sectors, such as:

-

Power Generation — leveraging circulating fluidized bed boiler (CFB) designs for high efficiency and emission control.

-

Pulp and Paper — using fluidized bed combustion boilers for consistent steam in cooking and drying processes.

-

Chemical and Pharmaceutical — where precise, stable heat is essential.

-

Food and Beverage — requiring clean, contaminant-free steam.

Over the past five decades, fluidized bed combustion technology has progressed from basic atmospheric fluidized bed combustion (AFBC) to advanced circulating fluidized bed boilers (CFBC) and even pressurized fluidized bed combustion (PFBC), now common in modern power plants.

In Vietnam, the adoption of fluidized bed boiler systems started in the early 2000s, driven by the shift from fossil fuels to biomass and renewable fuels. Divi Group emerged as a pioneer, localizing and customizing fluidized bed combustion boiler designs to suit a wide range of fuels, including:

-

Biomass: coffee husks, sawdust, bagasse

-

Agricultural waste: rice husks, cashew shells, corn cobs

-

Industrial byproducts: peat, oil sand, dried sludge

By integrating operational experience, optimizing engineering for Vietnam’s fuel characteristics, and investing in automated control systems, Divi Group has enabled numerous enterprises to adopt sustainable, cost-saving, and eco-friendly steam solutions.

Common types of fluidized bed boilers

Modern fluidized bed boiler technology has evolved into multiple configurations to meet diverse industrial requirements. Below are the three most widely used types:

Bubbling Fluidized Bed Boiler (BFB / AFBC)

Bubbling fluidized bed boiler (BFB)

Bubbling fluidized bed boiler (BFB)Also known as atmospheric fluidized bed combustion boilers, BFB systems are the most widely adopted subtype of fluidized bed boiler technology. Their popularity stems from a cost-effective design, operational simplicity, and reliability in handling diverse fuel types, including biomass, low-grade coal, and various industrial residues.

These fluidized bed combustion boilers operate under atmospheric pressure, with gas velocities typically ranging from 1.5 to 2.5 m/s—a range that ensures stable fluidization without excessive erosion or mechanical wear. The combustion process primarily occurs in a bubbling fluidized bed layer situated near the furnace base, where solid fuel particles and inert materials such as sand or ash create a dynamic medium for continuous and efficient combustion.

One of the defining features of this configuration is the localized combustion zone concentrated in the lower chamber. The fluidization process keeps fuel particles in suspension, enabling excellent mixing with combustion air and maintaining an ideal reaction temperature around 850°C. This thermal environment helps minimize the formation of nitrogen oxides (NOx) while still ensuring complete fuel burnout.

As an entry-level fluidized bed boiler, BFB systems are especially suitable for medium-scale industries that prioritize fuel flexibility, low emissions, and manageable capital investment.

| Advantages | Disadvantages |

|---|---|

| Lower initial investment | Lower combustion efficiency compared to CFB |

| Simple design, easy to maintain | Not suitable for large-scale or high-temperature operations. |

| Suitable for a wide range of fuels including biomass and low-grade coal |

Circulating Fluidized Bed Boiler (CFB)

The circulating fluidized bed boiler (CFB) represents an advanced and highly efficient evolution of fluidized bed boiler technology. It is a significant upgrade from traditional bubbling bed systems, offering improved thermal performance and reduced emissions. Unlike bubbling fluidized bed boilers, CFB boilers operate with higher fluidization velocities—typically between 4 to 6 meters per second—which effectively suspend and transport both fuel particles and inert materials throughout the furnace.

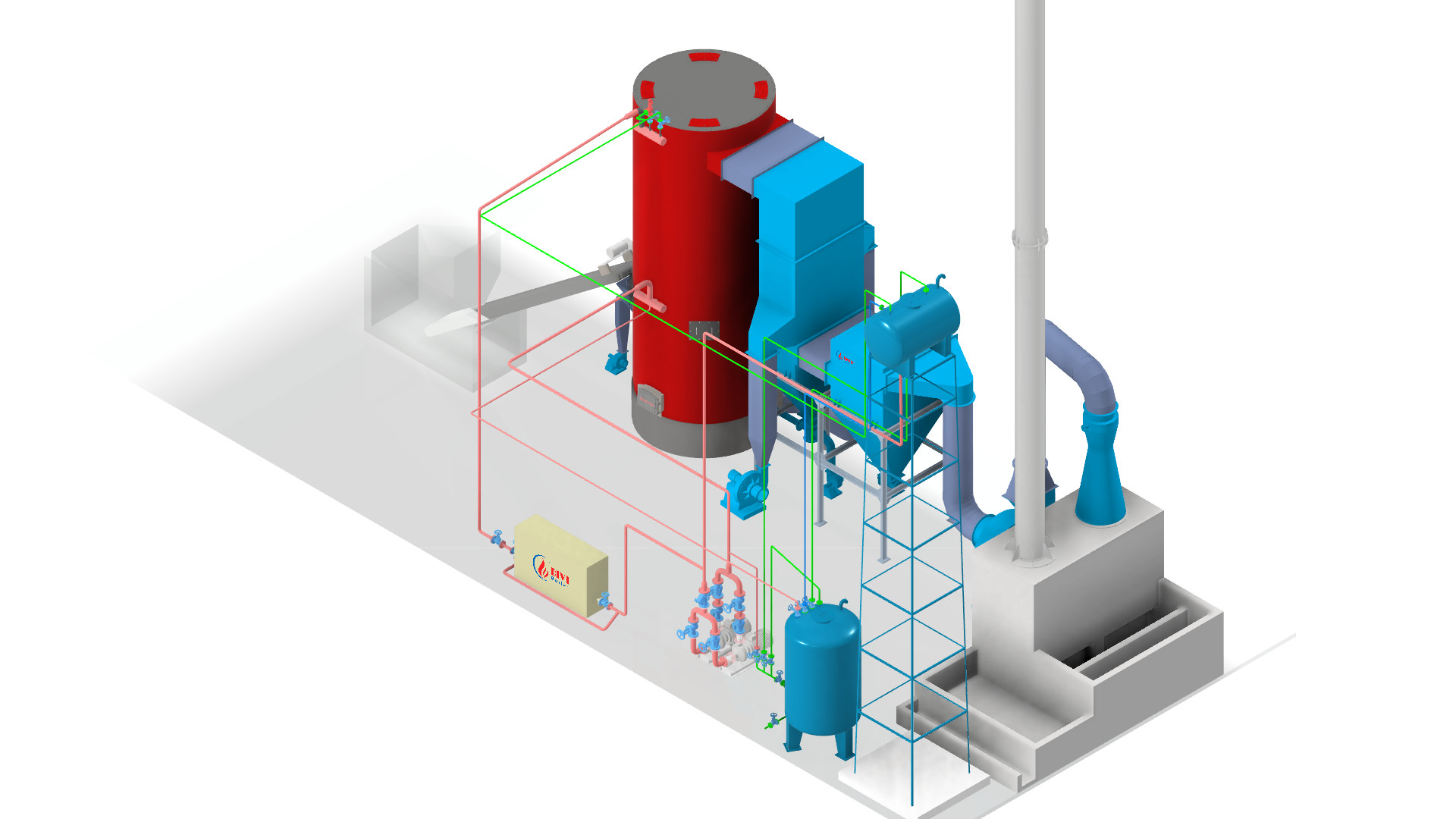

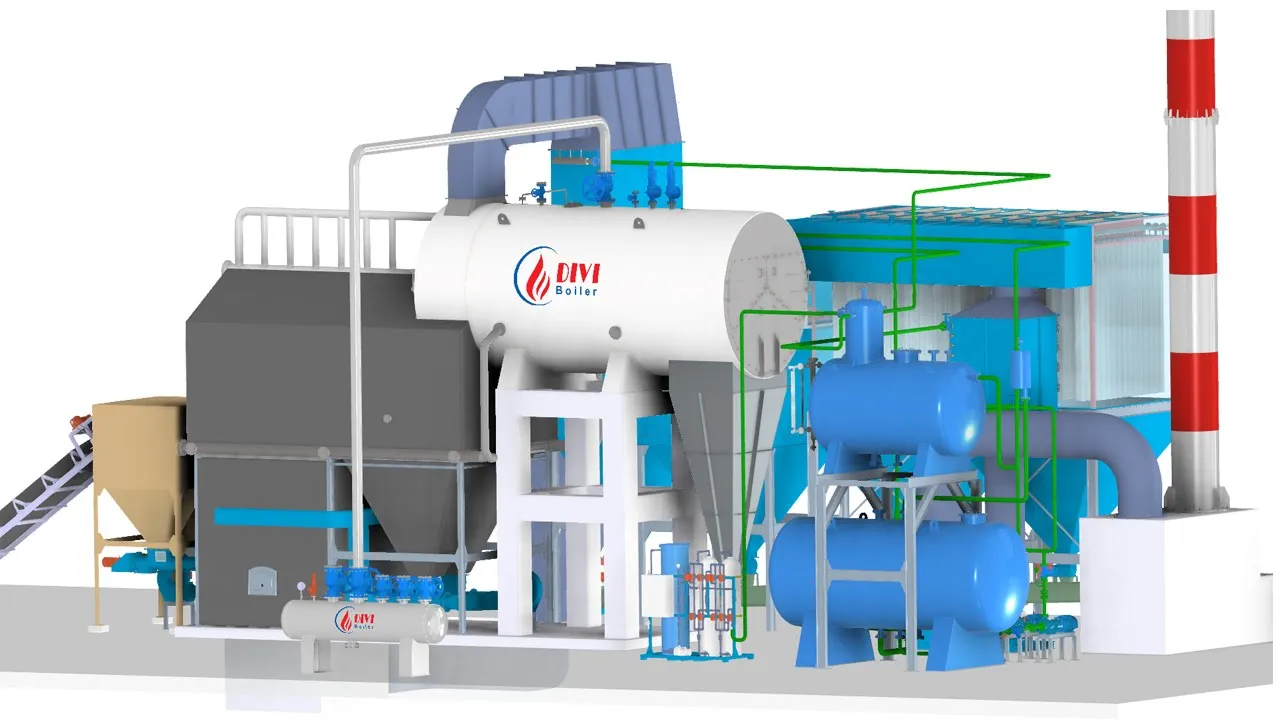

Biomass-Fired fluidized bed boiler by Divi Group

Biomass-Fired fluidized bed boiler by Divi GroupThe mixture of combustion gases, ash, and unburned fuel is continuously carried into a cyclone separator, which removes heavier solids from the gas stream. These captured particles are then recirculated back into the combustion chamber, forming a closed-loop system known as the solids recirculation loop. This mechanism significantly increases the fuel residence time, allowing for nearly complete combustion and a dramatic reduction in unburned carbon and particulate emissions.

By integrating these features, circulating fluidized bed boilers achieve exceptional combustion efficiency, making them ideal for high-capacity thermal power plants and industrial operations that demand consistent heat output, low NOx/SOx emissions, and the flexibility to burn low-grade fuels such as biomass, municipal solid waste, or industrial sludge. These characteristics position CFB systems as one of the most advanced types of fluidized bed combustion boiler available today.

| Advantages | Disadvantages |

|---|---|

| Superior combustion efficiency | Higher capital and O&M costs |

| Lower NOx and SOx emissions due to in-bed desulfurization | Requires specialized operators and advanced control systems |

| Ideal for large-capacity applications (e.g., power plants >100 TPH) |

Pressurized Fluidized Bed Boiler (PFBC)

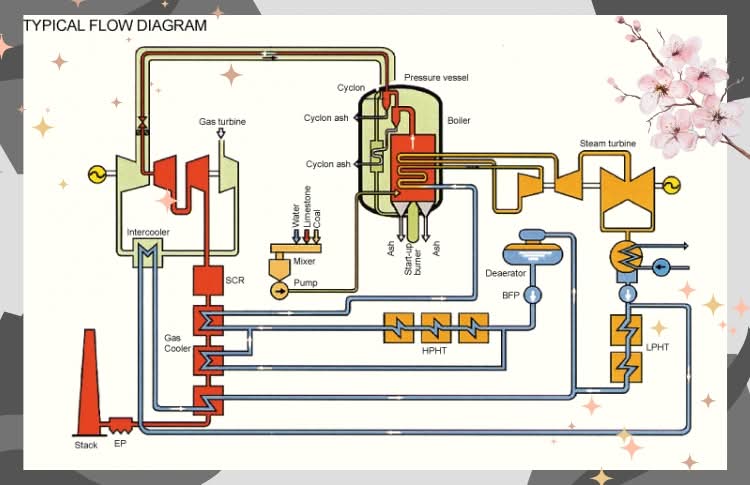

Pressurized fluidized bed boiler (PFBC)

Pressurized fluidized bed boiler (PFBC)The pressurized fluidized bed combustion boiler (PFBC) is a next-generation design that combines fluidized bed combustion technology with gas turbine integration, forming a highly efficient combined-cycle power generation system. Unlike conventional fluidized bed boilers, which operate at atmospheric pressure, PFBC systems work under elevated pressures ranging from 6 to 16 bar, allowing them to produce electricity at much higher efficiencies.

In a PFBC system, the fluidized bed combustion boiler burns fuel in a pressurized environment, where hot gases generated from combustion are routed through a gas turbine before being used to create steam in a heat recovery steam generator (HRSG). This dual-use of thermal energy significantly enhances total plant efficiency while minimizing waste heat.

One of the most innovative aspects of PFBC is its ability to handle desulfurization in-bed, thanks to the addition of limestone directly into the combustion chamber. This allows the system to capture sulfur oxides (SOx) at the source, reducing emissions by up to 90% without the need for expensive post-combustion treatment.

This advanced type of fluidized bed combustion boiler offers compact design, lower emissions, and the potential to burn challenging fuels such as biomass, high-sulfur coal, and industrial sludge—making it ideal for applications where emission control and space efficiency are top priorities.

Though not yet widely adopted in Vietnam, PFBC systems are gaining attention in regions like Europe and North America, particularly in high-tech thermal power stations. Their long-term viability lies in their ability to support carbon reduction goals, adapt to net-zero energy strategies, and integrate seamlessly into hybrid renewable systems.

| Advantages | Disadvantages |

|---|---|

| Very high thermal and electrical efficiency | Very high capital investment. |

| Can reduce SOx by up to 90% using limestone in-bed | Not yet common in Vietnam |

| Compact design suitable for modern plants | Compact design suitable for modern plants |

Key Components of a Fluidized Bed Boiler System

A modern fluidized bed boiler consists of several integrated subsystems, each designed to support safe, stable, and efficient operation. The main components of a typical fluidized bed combustion boiler are as follows:

1. Fuel Feeding System

This subsystem is responsible for delivering a continuous and controlled supply of fuel into the combustion chamber. Various types of fuel—such as biomass, coal, or industrial waste—are fed into the fluidized bed boiler through screw feeders, belt conveyors, or hopper systems. A well-designed feeding system ensures uniform distribution of fuel and prevents clogging or overloading, which can disrupt combustion.

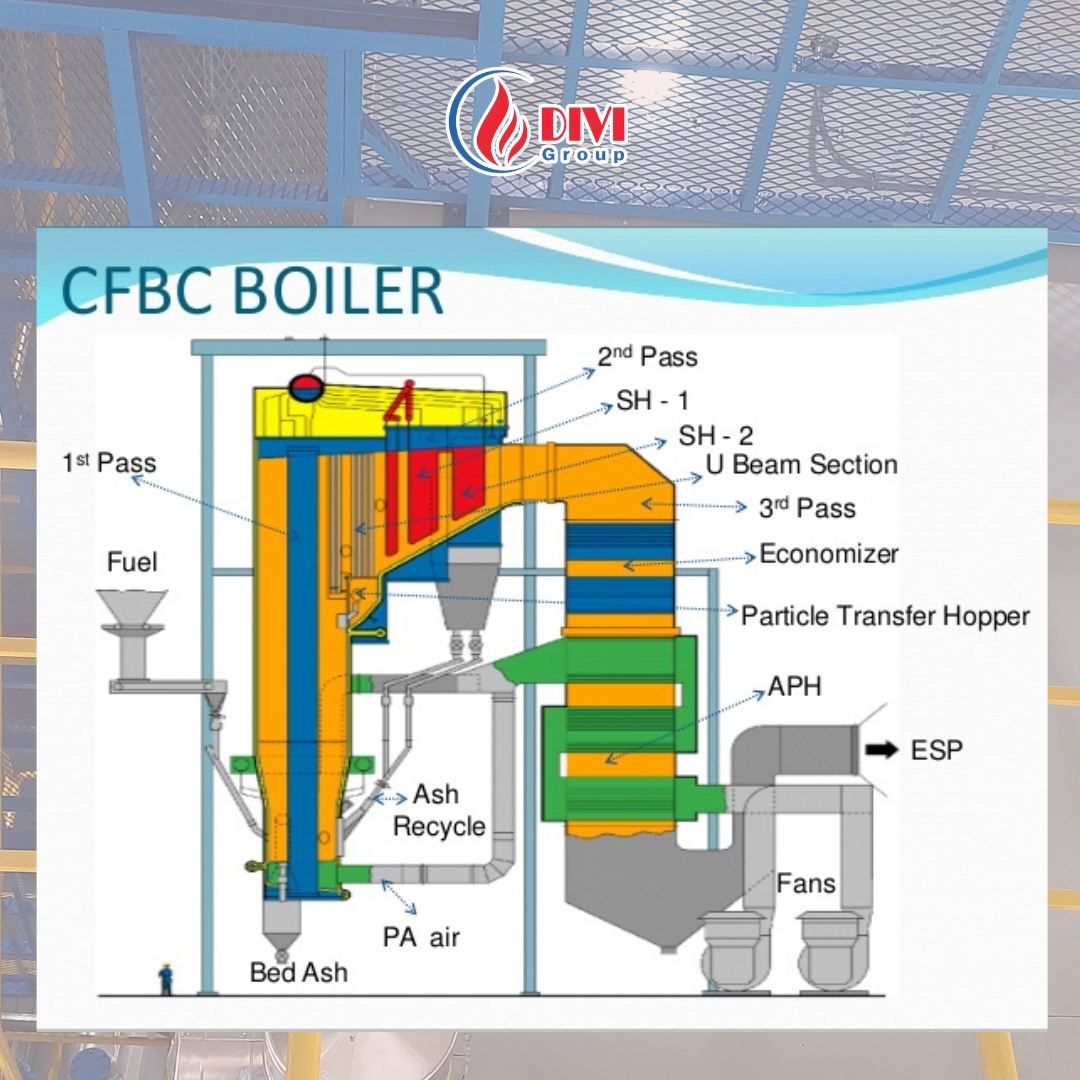

2. Combustion Chamber

The heart of any fluidized bed boiler, the combustion chamber is where the reaction between fuel and air takes place. In bubbling fluidized bed boilers (AFBC), combustion occurs near the bottom layer, within the bubbling bed of inert particles. In contrast, circulating fluidized bed boilers (CFBC) maintain higher flow velocities that suspend and recirculate solid particles, enabling nearly complete combustion and extended fuel utilization.

3. Air and Flue Gas System

This system includes forced draft (FD) fans, induced draft (ID) fans, and ductwork, all working together to supply combustion air and extract flue gases. In circulating fluidized bed boilers, the system is more complex, incorporating a cyclone separator to capture unburned solids from the flue stream and redirect them into the furnace for re-combustion.

4. Ash Removal and Emission Control System

Once combustion is complete, leftover residues—mainly bottom ash and fly ash—are removed through a dedicated ash handling system. Meanwhile, flue gases pass through emission control devices, such as bag filters or electrostatic precipitators, which help reduce particulate matter and remove harmful substances before releasing the gases into the environment.

5. Steam Generation Unit

This segment of the boiler contains water walls, steam drums, and heat exchanger tubes, responsible for converting combustion heat into steam energy. The generated steam can be used for industrial heating processes or directed into steam turbines for electricity production. The efficiency of this section greatly influences the overall performance of the fluidized bed combustion boiler system.

Operating Principle of a Fluidized Bed Boiler

The working principle of a fluidized bed boiler, whether of the bubbling or circulating type, is based on a closed-loop combustion cycle. The entire process is carefully controlled to maximize fuel combustion efficiency and steam output. Below are the key operational stages of a modern fluidized bed combustion boiler:

Working principle of fluidized bed boiler

Working principle of fluidized bed boilerStep 1: Continuous and Automated Fuel Feeding

Solid fuels—including wood chips, rice husks, sawdust, peat, or biomass—are introduced into the boiler through automated systems such as belt conveyors, screw feeders, or pneumatic valves. The feeding mechanism is enclosed to prevent dust emission and designed to maintain a stable and precise fuel input flow.

Step 2: Creation of the Fluidized Bed via Air Supply

Clean air is supplied from the base of the furnace using high-capacity forced draft fans. This air passes through a bed of inert materials (usually sand, fly ash, or heat-resistant aggregates). When the air pressure exceeds a specific threshold, the bed material becomes suspended and starts to “boil,” creating a fluidized environment that ensures even heat distribution and turbulence—core characteristics of a fluidized bed boil

Step 3: Combustion in a Stable Fluidized Zone

In this highly reactive environment, solid fuel particles are suspended in hot air and come into contact with oxygen from all directions. The result is an extremely efficient and uniform combustion process. Unlike traditional furnaces, fluidized bed combustion boilers operate at lower temperatures (~850°C), significantly reducing NOx and SOx formation while maintaining high thermal efficiency.

Step 4: Heat Transfer and High-Pressure Steam Generation

The heat produced from combustion is absorbed by heat exchange surfaces, including water walls and steam-generating tubes. Water is converted into saturated or superheated steam, which can then be used for:

-

Driving steam turbines for power generation

-

Supplying process steam to industrial lines

-

Industrial HVAC heating applications

Step 5: Ash Recovery and Emission Control

Residual materials—such as fly ash, bottom ash, and unburned solids—are managed through:

-

Cyclone separators or bag filters for particulate recovery

-

Recirculation systems in circulating fluidized bed boilers to reuse unburned fuel

-

Ash hoppers for safe collection and environmental disposal

Advanced systems may also incorporate waste heat recovery units to extract additional energy from flue gases, enhancing the overall efficiency of the fluidized bed boiler system.

Advantages and Disadvantages of Fluidized Bed Boilers

Understanding the pros and cons of a fluidized bed boiler system is essential for industries evaluating long-term operational efficiency, fuel flexibility, and compliance with environmental regulations. Below is a comprehensive overview of the benefits and challenges associated with fluidized bed combustion boiler technology:

Advantages of Fluidized Bed Boilers:

-

High combustion efficiency: Both bubbling fluidized bed boilers and circulating fluidized bed boilers ensure more complete fuel combustion, allowing higher heat output with lower fuel consumption.

-

Environmentally friendly performance: Thanks to uniform combustion at lower temperatures, these systems produce fewer greenhouse gases and reduce pollutants such as NOx and SOx, making them compliant with modern environmental standards.

-

Fuel flexibility: A major strength of fluidized bed combustion boilers is their ability to handle various fuels—ranging from biomass and coal to municipal solid waste—which enables operators to reduce fuel costs and adapt to supply availability.

-

Scalability and modular design: Particularly in circulating fluidized bed boilers, the modular system design makes it easier to scale for higher capacities, making them suitable for both industrial and utility-scale applications.

Disadvantages of Fluidized Bed Boilers:

-

High capital investment: The initial setup cost for a fluidized bed boiler can be considerably higher than that of conventional grate or pulverized coal systems. However, this is often offset over time by reduced fuel costs and longer operational lifespan.

-

Operational complexity: Running a fluidized bed combustion boiler requires a skilled workforce to manage airflow rates, fuel distribution, bed temperature, and ash removal. This makes training and technical support essential for efficient operation.

-

Maintenance demands: Due to the abrasive nature of the fluidized bed materials and high turbulence, these systems may require more frequent inspection and wear-resistant design considerations.

Despite these challenges, the long-term energy savings, environmental advantages, and operational adaptability make fluidized bed boilers a compelling choice for industries aiming to achieve sustainable heat and power generation.

Fluidized Bed Boiler vs. Traditional Boiler: A Comparative Overview

When evaluating different boiler systems, it's essential to consider performance, fuel flexibility, environmental impact, and operational costs. The table below compares fluidized bed boilers to conventional boiler systems across several critical metrics:

| Criteria | Fluidized Bed Boiler / Fluidized Bed Combustion Boiler | Traditional Boiler |

|---|---|---|

| High | Moderate to Low | |

| Fuel Savings | Excellent | Average |

| Fuel Flexibility | Highly flexible (biomass, waste, coal, RDF) | Limited |

| Emissions (NOx/SOx/PM) | Low (due to lower temp + in-bed desulfurization) | High |

| Operating Costs | Low over the long term | Higher over time |

This comparison highlights how a fluidized bed boiler, particularly in the form of a circulating fluidized bed boiler, significantly outperforms traditional models in terms of energy efficiency, fuel adaptability, and emissions control.

Fluidized bed combustion boilers offer a smarter and more sustainable approach to steam generation—ideal for industries aiming to reduce carbon footprints while keeping operational expenses in check.

Industrial Applications of Fluidized Bed Boilers

Fluidized bed boiler technology is gaining widespread industrial adoption thanks to its fuel flexibility, combustion efficiency, and low environmental footprint. Below are some of the key sectors utilizing fluidized bed combustion boiler systems:

-

Food & Agro-Processing: used for drying, sterilization, and distillation. Biomass fuels like rice husks and sawdust help reduce both energy costs and emissions.

-

Pulp & Paper: supplies heat for pulp digestion and paper drying. Able to burn wood waste, paper sludge, and other industry by-products.

Power generation sector

Power generation sector

-

Power Generation: drives steam turbines using high-pressure steam. Circulating fluidized bed boilers (CFBC) and pressurized fluidized bed boilers (PFBC) are ideal for medium to large-scale electricity generation.

-

Chemical & Pharmaceutical: provides stable, clean steam for critical chemical reactions and controlled heating processes.

Metallurgy and mechanical engineering Industry

Metallurgy and mechanical engineering Industry

-

Metallurgy & Mechanical Engineering: Used in metal treatment, rolling, welding, and forging where continuous high steam output is required.

Why Industries Prefer Fluidized Bed Boilers?

-

Fuel flexibility: burns biomass, waste, agricultural residues, and low-grade coal.

-

Lower O&M cost: clean combustion reduces fouling and power consumption.

-

Environmental compliance: cuts NOx/SOx emissions by 40–70% vs. traditional systems.

-

Automation ready: easily integrates with modern PLC/SCADA systems.

-

Durability: supports continuous operation with extended service life.

What types of fuel can a fluidized bed boiler use?

One of the biggest advantages of a fluidized bed boiler is its exceptional fuel flexibility. These systems can burn a wide range of solid fuels including: biomass, coal, industrial waste, municipal solid waste.. This flexibility helps reduce fuel costs and allows industries to utilize waste streams, supporting both sustainability and economic efficiency.

Are fluidized bed boilers easy to maintain?

Proper maintenance is crucial to ensuring the long-term performance of any fluidized bed combustion boiler. While circulating fluidized bed boilers may involve more complex systems, modern automation makes them easier to manage. Key maintenance steps include:

-

Monitoring fuel distribution: Ensuring uniform feed to prevent localized overheating or clogging.

-

System cleaning: Keeping air and flue pathways clear for optimal combustion.

-

Routine checks: Inspecting wear-resistant linings, air nozzles, and recirculation loops.

With regular inspections and proactive servicing, fluidized bed boilers can deliver high uptime, stable output, and long operational life.

Advanced Technologies in Fluidized Bed Boilers

To meet increasing industrial demands, modern fluidized bed boiler systems—especially those developed by Divi Group—now integrate cutting-edge technologies that enhance performance, safety, and environmental compliance.

-

Automation and Smart Controls: Advanced control systems regulate air-to-fuel ratios and bed temperature automatically, improving combustion efficiency and fuel savings.

-

Low-Emission Design: Integrated dust collectors and desulfurization units minimize NOx, SOx, and particulate emissions, ensuring the fluidized bed combustion boiler meets strict environmental regulations.

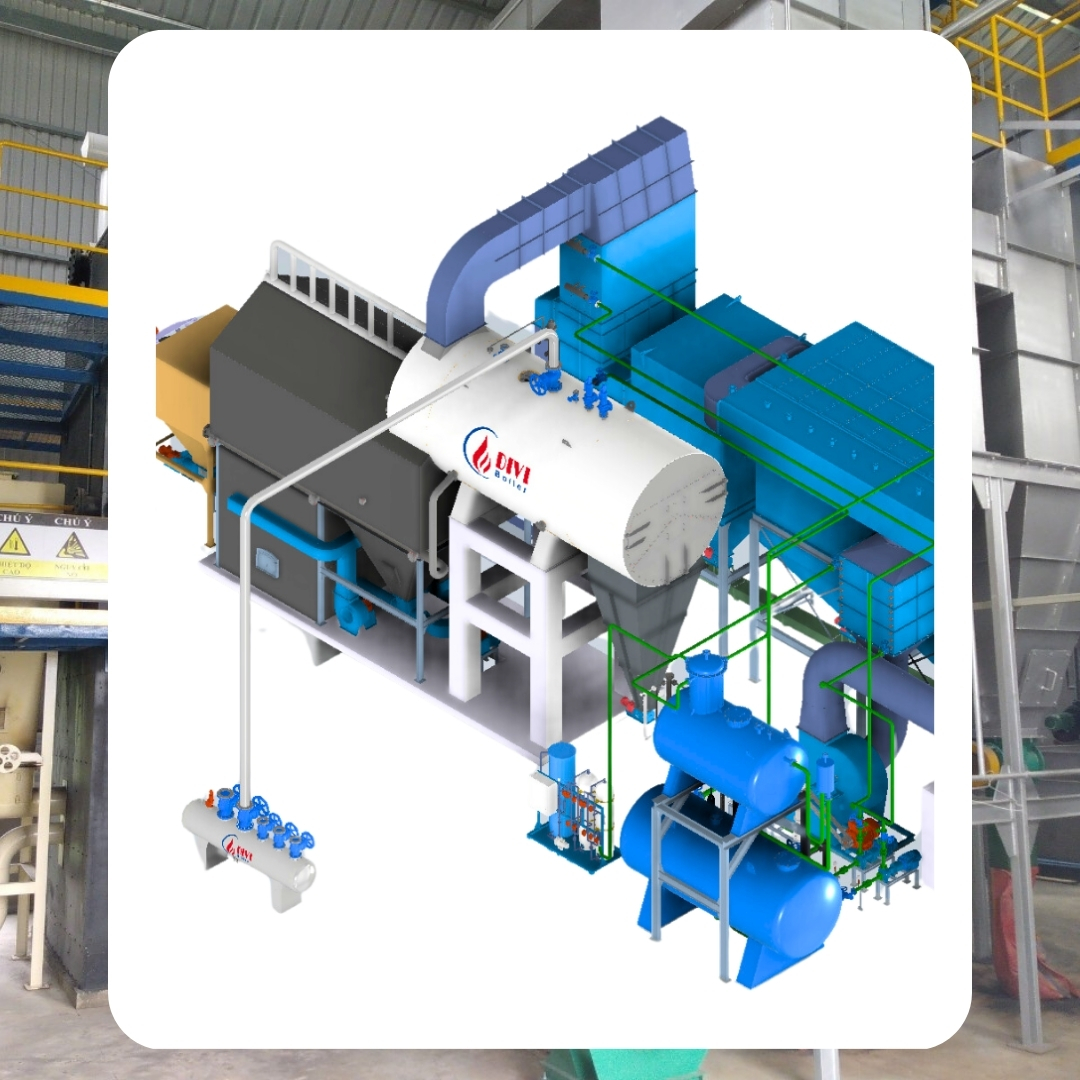

Divi Group Boiler at Tuong An, Phu My Facility

Divi Group Boiler at Tuong An, Phu My Facility-

Remote Monitoring and Diagnostics: Equipped with IoT-enabled sensors, the system allows operators to track real-time performance, receive alerts, and schedule maintenance proactively—even in circulating fluidized bed boiler setups.

These advancements position fluidized bed boilers as a forward-looking solution for industries prioritizing sustainability, automation, and long-term operational reliability.

Why Choose Fluidized Bed Boilers from Divi Group

When selecting a fluidized bed boiler solution, Divi Group stands out as a trusted partner in the industry. We deliver more than just high-performance fluidized bed combustion boilers—we provide end-to-end support from consultation and custom engineering to installation and long-term maintenance.

Our expert team of engineers ensures that every circulating fluidized bed boiler or bubbling fluidized bed system is tailored to meet your fuel type, capacity needs, and emission goals. With years of proven experience and an emphasis on sustainable, cost-effective technologies, Divi Group helps clients maximize return on investment while minimizing operational risks.

Whether you're upgrading your current system or investing in a new energy solution, Divi Group’s fluidized bed boiler technology offers reliability, flexibility, and long-term efficiency.

Frequently Asked Questions (FAQ)

1. How does a fluidized bed boiler work?

A fluidized bed boiler operates using a bed of inert material, such as sand, that is fluidized by air blown from beneath the furnace. This creates a suspended, bubbling layer in which solid fuels like rice husks, sawdust, or coal are burned evenly and efficiently. The process ensures complete combustion and reduces NOx and SOx emissions.

2. What’s the difference between CFBC and BFB?

A circulating fluidized bed boiler (CFBC) uses higher gas velocities (4–6 m/s) and recirculates unburned fuel particles to increase combustion efficiency (up to 95%). It's ideal for power plants and heavy industry. A bubbling fluidized bed boiler (BFB), by contrast, has a simpler structure and operates at lower air velocity, making it suitable for small to medium-scale industries.

3. Are operating costs high for fluidized bed boilers?

While fluidized bed boilers may require higher upfront investment, they offer lower long-term operating costs thanks to:

-

Fuel flexibility (burning cheap biomass, industrial waste, or peat)

-

High combustion efficiency (less fuel required)

-

Lower maintenance needs with modern automation

4. What industries use circulating fluidized bed boilers?

CFBC systems are ideal for:

-

Large-scale power generation

-

Cement, chemical, and metallurgical industries

-

Large biomass and waste-to-energy projects Their high heat control and emission reduction capabilities make them a top choice for environmentally demanding operations.

Conclusion:

Biomass-fueled fluidized bed boilers offer a powerful solution for modern industry. They maximize fuel efficiency, reduce carbon emissions, and provide long-term savings through flexible fuel usage. Their ability to burn a variety of low-cost fuels like biomass and waste makes them a sustainable choice for businesses.

Investing in a fluidized bed combustion boiler is not only a smart economic move—it’s also an environmentally responsible strategy. With careful system selection, proper operation, and routine maintenance, these systems deliver long-lasting benefits in both performance and compliance.

DIVI Group's Boiler Products:

Other news

-

Steam Separator – An Effective Solution for Dry Steam

29/12/2025, -

Treating High CO Emissions in Fixed-Grate Boilers – Is Boiler Replacement Necessary? Practical Solutions from DIVI

18/12/2025, -

What Is a Steam Trap? Principles, Types, and How to Select the Right Steam Trap for Your Steam System

07/12/2025, -

COMPARISON OF STEAM TRAPS: PRINCIPLES – EXPERIMENTS – OPTIMAL SELECTION FOR STEAM SYSTEMS

29/11/2025, -

Compact Biomass-Fired Boiler DVG-VN – The Optimal Fossil-Fuel Replacement Solution for Factories

23/11/2025, -

Which Boiler Should You Choose: Fixed Grate or Fluidized Bed? Detailed Efficiency, Cost & Environmental Comparison

24/06/2025, -

5 Common Mistakes in Industrial Steam Distribution Systems

11/06/2025, -

Mr. Boiler Speaks: Wake-Up Call from an Industrial Icon

09/06/2025, -

What is a Thermal Oil Heater? Structure, Benefits & Safety Tips

27/05/2025, -

3 Danger Signs of Boiler Operation You Should Never Ignore

24/05/2025,

EN

EN