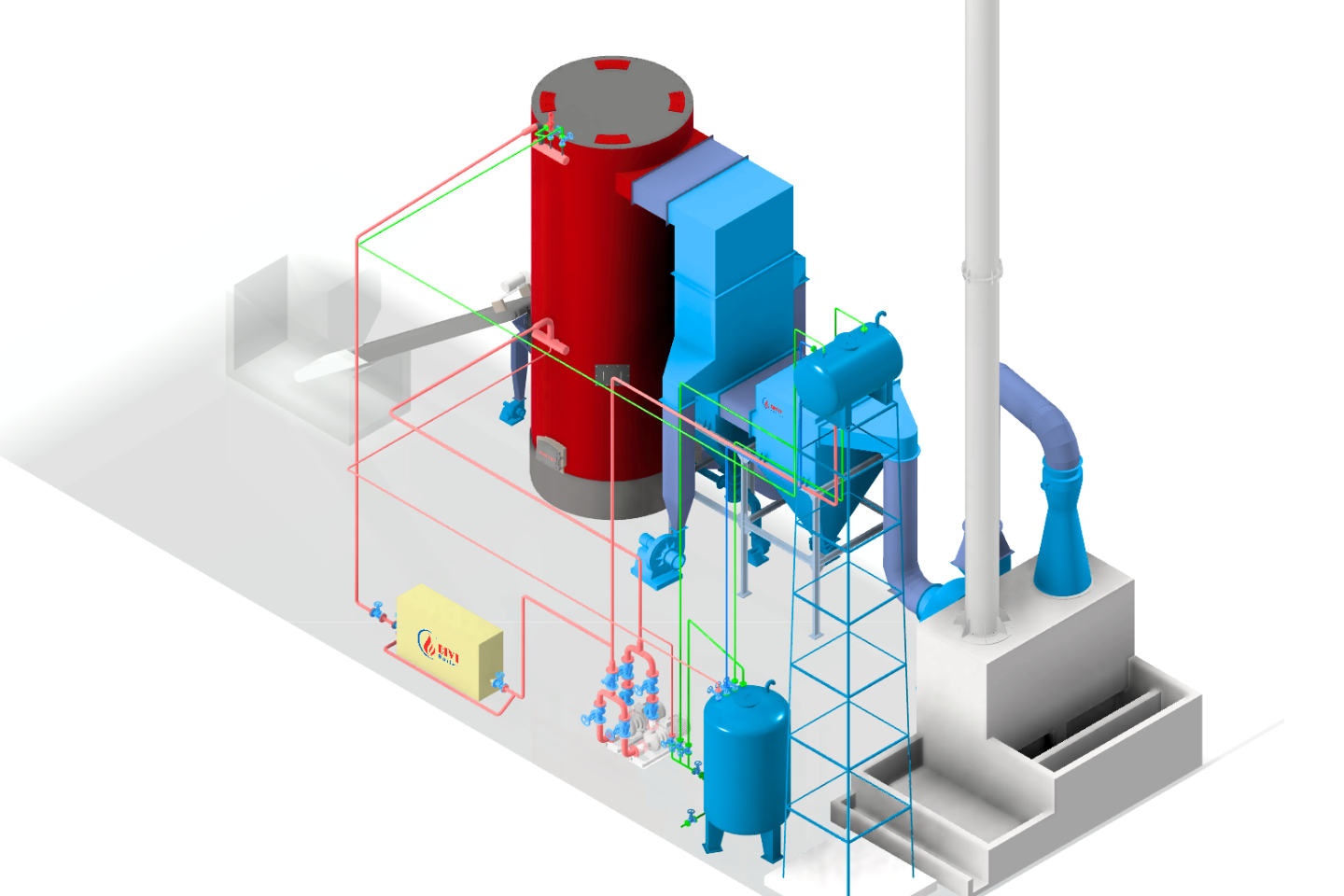

Are you looking for an industrial boiler system that helps save fuel costs while remaining eco-friendly? The fluidized bed biomass boiler from DIVI Group is your optimal solution — delivering performance, flexibility, and sustainability.

Why Choose DIVI Fluidized Bed Biomass Boiler?

1. Flexible Renewable Fuels – Lower Operating Costs

DIVI’s fluidized bed boiler is designed for multi-fuel combustion. You can burn a wide range of biomass fuels such as rice husk, sawdust, cashew shell residue, or even coffee husks — all of which are abundant and affordable in Vietnam.

This not only reduces your dependency on fossil fuels, but also allows you to utilize agricultural and forestry waste, cutting costs and contributing to a circular economy.

2. High Efficiency – Optimized Energy Utilization

DIVI biomass boilers achieve up to 89% thermal efficiency thanks to advanced combustion technology and multi-stage heat recovery systems such as economizers and air preheaters.

These components recover and reuse waste heat, helping your business save more on fuel without compromising steam generation capacity.

3. Versatile Industrial Applications

This biomass steam boiler is ideal for industries requiring high performance and adaptability, such as:

-

Breweries and Beverage Plants

-

Food Processing

-

Chemical & Petrochemical Industry

Its fast steam generation and automatic load adjustment ensure optimal operation even under fluctuating demand.

4. Advanced Automation – Full Remote Monitoring

The system features PLC–SCADA automation, allowing operators to monitor and control the boiler remotely via internet and RS485 port. Fuel feed rate and combustion temperature are automatically adjusted based on load demand.

This reduces human intervention, increases safety, and lowers labor costs.

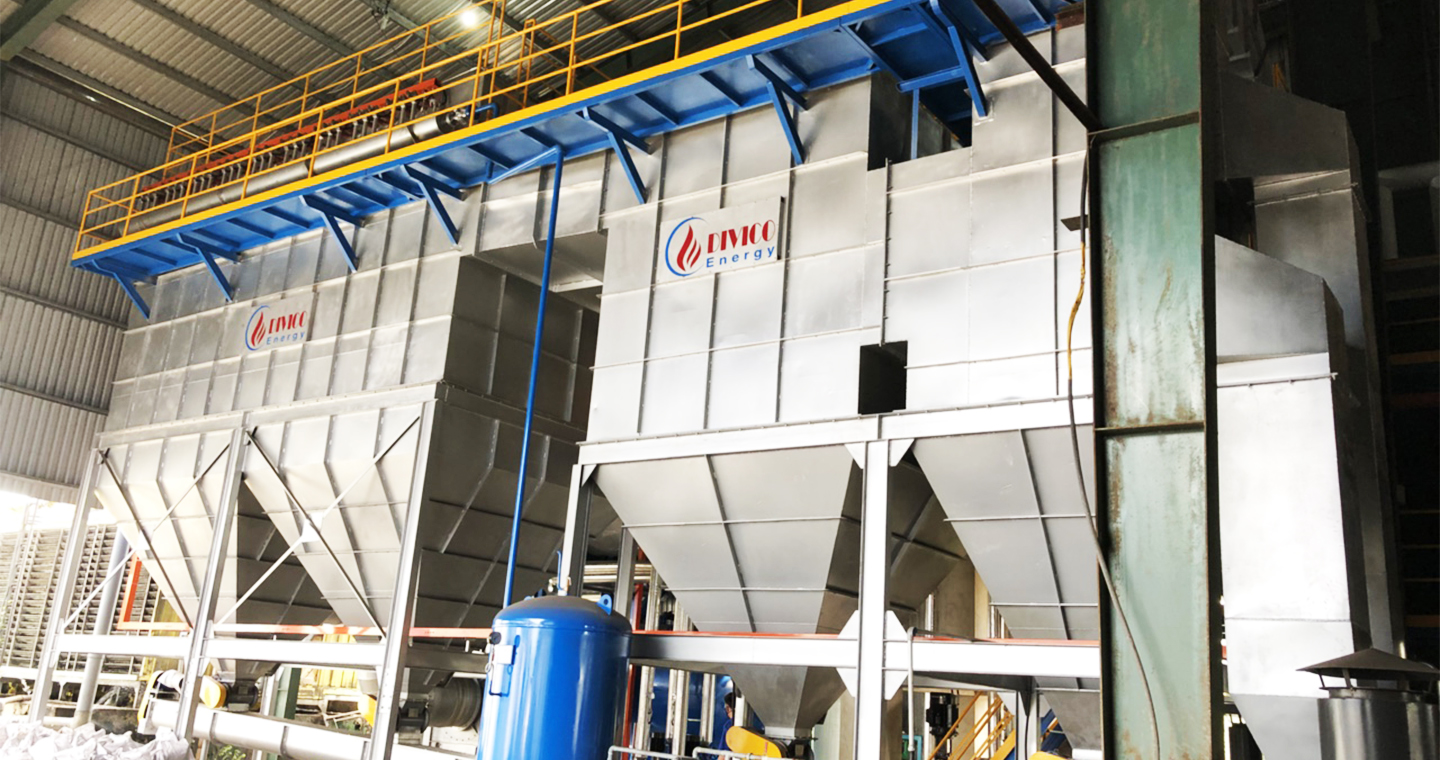

5. Robust Design – Easy Maintenance

Key components are manufactured using CNC precision machining and fitted with bearings from Japan and Germany for superior durability. Low-speed fan design minimizes dust abrasion, extending equipment life and reducing maintenance frequency.

Economic Benefits of Fluidized Bed Biomass Boiler

1. Significant Fuel Cost Savings

Biomass fuels like rice husk and sawdust are significantly cheaper than oil or gas. The fuel cost gap gives your business a competitive edge, especially when fossil fuel prices surge.

2. Superior Energy Efficiency

Advanced heat recovery and combustion control result in lower fuel consumption, reduced energy waste, and higher profit margins.

3. Lower Labor Costs

With automated operation, fewer staff are needed. The system’s smart logic ensures reliable 24/7 performance with minimal human oversight.

4. Production Optimization

Fast steam response and flexible modulation allow your production to adapt to changing loads, minimizing downtime and maximizing throughput.

DIVI’s Commitment – Engineering Support You Can Trust

DIVI Group not only supplies high-quality fluidized bed boilers, but also offers end-to-end support, including:

-

Technical consultation

-

Customized system design

-

On-site installation & commissioning

-

Warranty & maintenance plans

Our experienced engineers are ready to accompany your business through every step of your steam journey.

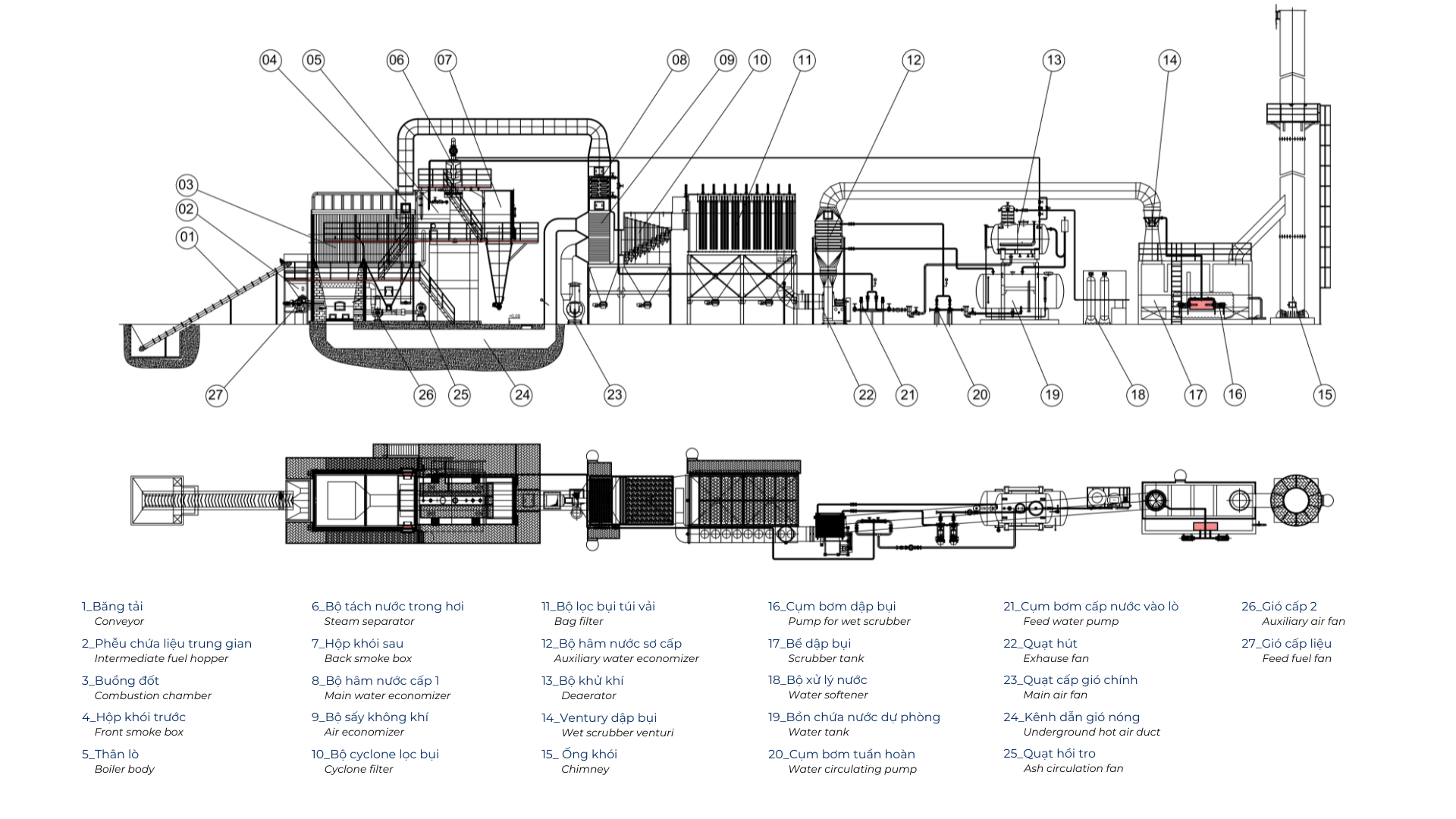

PRINCIPLE DIAGRAM

-

Basic specifications:

| Categories | Unit | Parameter | ||||||

| Design pressure | bar | 8 to 30 | ||||||

| Saturated steam temperature | °C | 165 to 234 | ||||||

| Boiler efficiency | % | 89 ± 2 | ||||||

| Fuel types | Rice husk, wood chips, cashew nut shells, sawdust, coffee husk and other types of biomass | |||||||

| Fuel consumption | kg/ton of steam | Wood chips | : 300 - 450 | |||||

| kg/ton of steam | Rice husk | : 170 - 250 | ||||||

| kg/ton of steam | Cashew nut shells | : 150 - 225 | ||||||

| Electric consumption | kW/ton of steam | Electricity | < 7,5 | |||||

| Control system | Fully automatic control using PLC – SCADA | |||||||

| Environmental standards | Ensure complete compliance with QCVN 19:2009/BTNMT | |||||||

| Boiler capacity | ton of steam/hour | 2 | 4 | 6 | 8 | 10 | 15 | 20 |

| Boiler house area | m² | 240 | 360 | 504 | 576 | 594 | 864 | 1.080 |

| Labor | person/shift | 2 | 2 | 2 | 2 | 3 | 3 | 3 |

| Power capacity | kW | 20 | 40 | 60 | 80 | 100 | 150 | 200 |

product video

Other Product

Electric Resistance Steam Boiler DIVI DVG-LD

Compact Biomass Boiler DIVI DVG-VN

The DVG-VN Compact Biomass Steam Boiler – a space-efficient industrial steam solution delivering up to 92% thermal efficiency.

Engineered for versatile fuel compatibility, it operates effectively with wood pellets, cashew shell pellets, palm kernel shells, and peat briquettes.

Designed for economical operation, safety, and environmental sustainability, the DVG-VN series is manufactured by DIVI Group Vietnam to meet modern industrial steam demands with reliability and outstanding energy performance.

Biomass-fired Thermal Oil Boiler

Biomass-fired Thermal Oil Boilers" manufactured by DIVI Group have the same advantages as the "Fluidized Bed Biomass Boilers" technology. The only difference is the medium used by the Thermal Oil Boiler is heat transfer oil, whereas the Fluidized Bed Boiler uses water vapor.

Oil-Fired & Gas-Fired Steam Boiler

Are you looking for an oil-fired or gas-fired steam boiler that helps save fuel while ensuring high performance? With advanced combustion technology, this is an ideal solution for various industries — optimizing operating costs while meeting strict production demands.

EN

EN