What is a Boiler Deaerator? Benefits, Functions, and Applications

Hello everyone, today we’ll dive into a topic that may sound a bit technical at first, but is absolutely crucial for those working in the field of boilers and industrial systems: The Benefits of Deaerators for Boilers. Have you ever wondered why factories invest in deaerator systems? Let’s explore this together with Divi Group!!

What is a Deaerator, and Why is it Crucial?

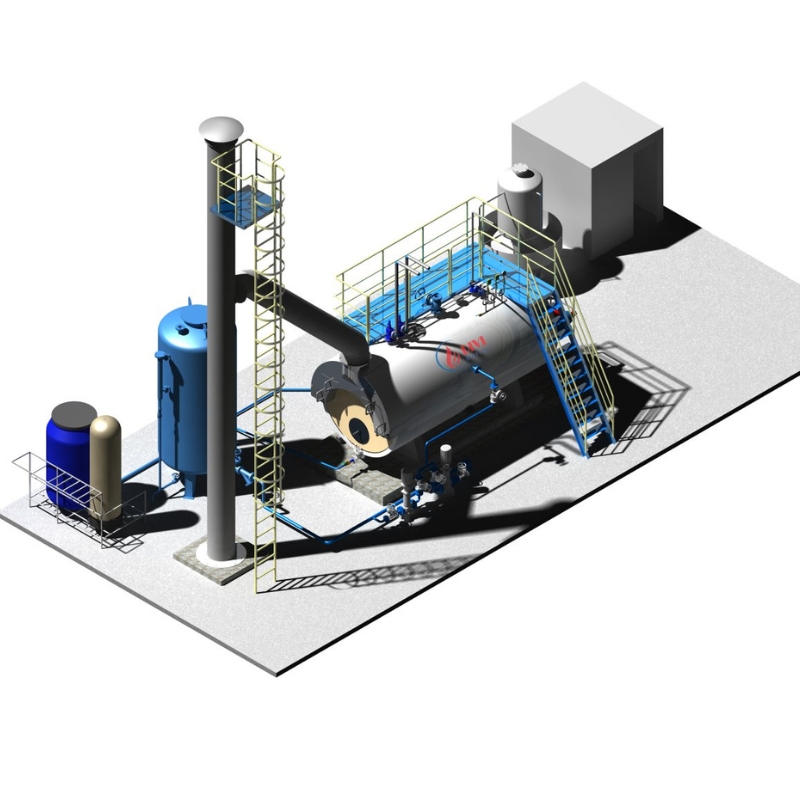

Boiler Deaerator (Steam Boiler) by Divi Group

Boiler Deaerator (Steam Boiler) by Divi GroupFirst, let’s understand what a deaerator is. It is a device designed to remove dissolved gases, primarily oxygen (O₂) and carbon dioxide (CO₂), from the feedwater supplied to boilers. While this might sound complex, the concept is actually quite straightforward. When water contains dissolved gases, these gases can cause corrosion to the metal components of the boiler system, reducing its lifespan and operational efficiency.

If you’ve ever seen a bicycle left outdoors rusting due to exposure to air and water, you’ll understand how similar corrosion can occur inside a boiler if dissolved gases are not removed. Deaerators are the solution to protecting boilers from corrosion and ensuring the system operates reliably.

Key Benefits of Deaerators

1. Enhancing Boiler Lifespan

Oxygen and carbon dioxide are major culprits of boiler component corrosion. By removing these gases, deaerators safeguard equipment integrity, minimize maintenance costs, and reduce the likelihood of premature system failures.

Proactive Protection

Think of deaerators as preventative care, much like repainting walls before cracks and chips escalate into bigger problems.

Boiler Deaerator (Steam Boiler) by Divi Group

Boiler Deaerator (Steam Boiler) by Divi Group2. Reducing Fuel Costs and Optimizing Efficiency

Deaerators significantly improve heating efficiency by ensuring feedwater is free of dissolved gases. With faster heating times and improved fuel utilization, operational costs decrease, leading to long-term savings.

Heating preconditioned water on a stove takes less time and fuel compared to starting with cold water. Boilers benefit similarly from deaerated water.

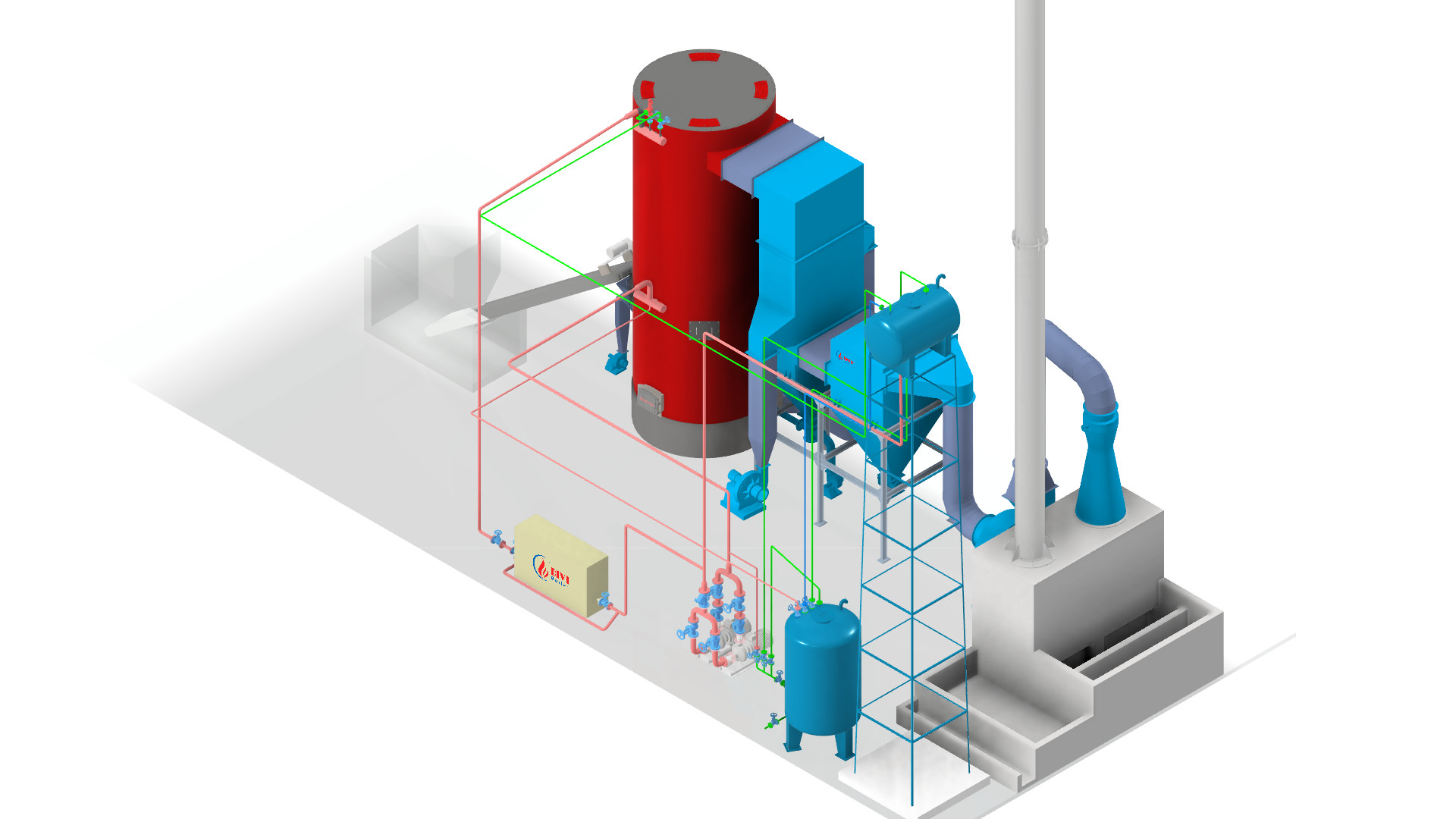

3. Maintaining Stable Boiler Pressure

The deaerator helps maintain stable pressure.

The deaerator helps maintain stable pressure.Dissolved gases can cause fluctuations in boiler pressure, disrupting steam generation. Deaerators stabilize this process, ensuring seamless and consistent boiler performance.

Driving on smooth roads allows for consistent speed, just as deaerators ensure stable boiler operations without "bumps" like pressure drops.

Conclusion

Using a deaerator not only extends the lifespan of your boiler but also saves fuel and ensures stable system operations. If you are considering investing in a boiler system, remember that a high-quality deaerator is essential for protecting and optimizing your entire operation process.

We hope this article has provided you with a comprehensive understanding of the importance of deaerators in industrial systems. If you have any further questions, feel free to leave a comment or reach out to us for additional advice!

Additional Reference Videos:

[DIVI] Reveal interesting things from steam boilers from the steam room for newcomerse

[DIVI] Boiler safety and practices for safe operation

DIVI Group's Boiler Products:

Other news

-

Steam Separator – An Effective Solution for Dry Steam

29/12/2025, -

Treating High CO Emissions in Fixed-Grate Boilers – Is Boiler Replacement Necessary? Practical Solutions from DIVI

18/12/2025, -

What Is a Steam Trap? Principles, Types, and How to Select the Right Steam Trap for Your Steam System

07/12/2025, -

COMPARISON OF STEAM TRAPS: PRINCIPLES – EXPERIMENTS – OPTIMAL SELECTION FOR STEAM SYSTEMS

29/11/2025, -

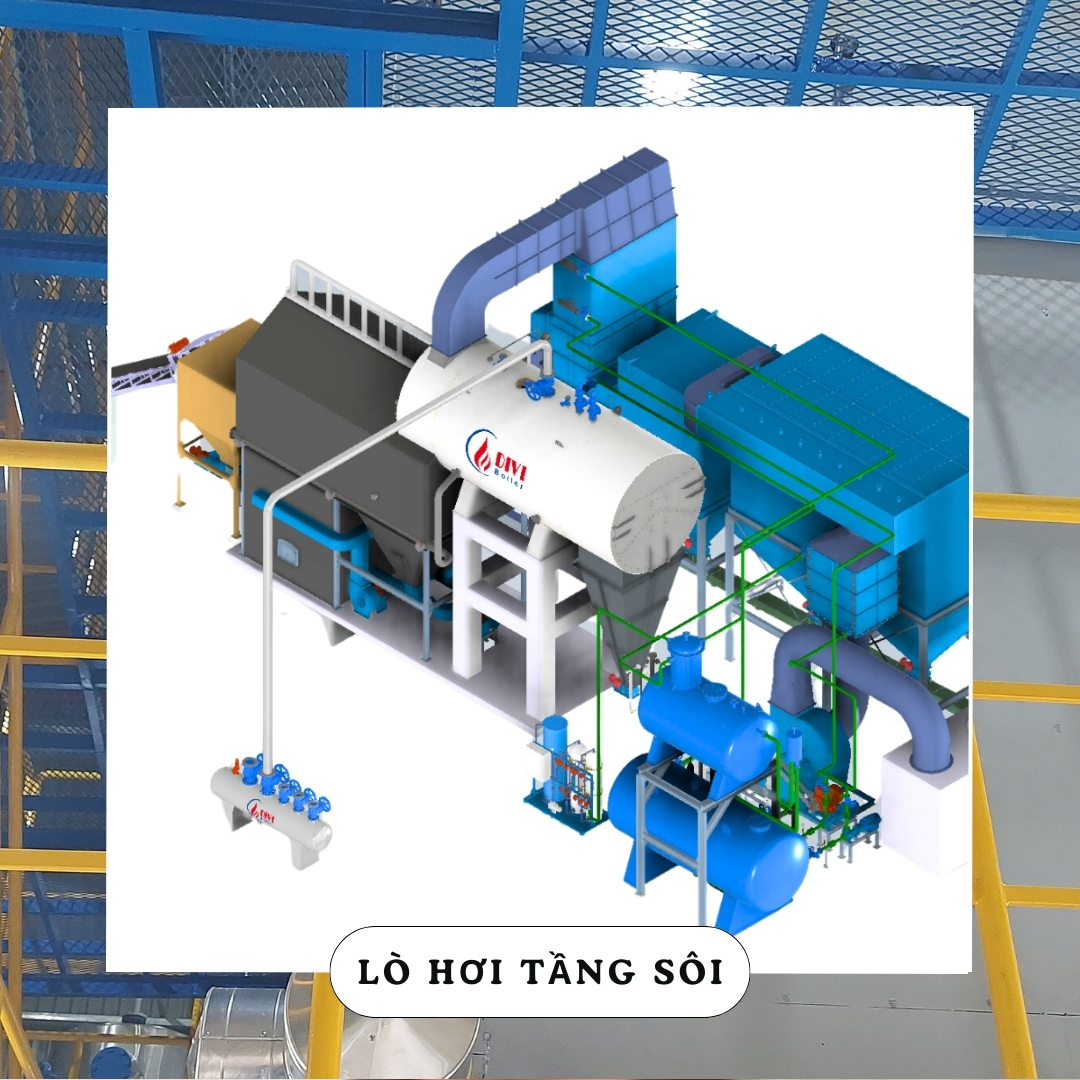

Compact Biomass-Fired Boiler DVG-VN – The Optimal Fossil-Fuel Replacement Solution for Factories

23/11/2025, -

Which Boiler Should You Choose: Fixed Grate or Fluidized Bed? Detailed Efficiency, Cost & Environmental Comparison

24/06/2025, -

5 Common Mistakes in Industrial Steam Distribution Systems

11/06/2025, -

Mr. Boiler Speaks: Wake-Up Call from an Industrial Icon

09/06/2025, -

What is a Thermal Oil Heater? Structure, Benefits & Safety Tips

27/05/2025, -

3 Danger Signs of Boiler Operation You Should Never Ignore

24/05/2025,

EN

EN