What is a Thermal Oil Heater? Structure, Benefits & Safety Tips

What makes a thermal oil heater the preferred choice over traditional steam boilers?

In recent years, thermal oil heaters have become indispensable in many industrial applications. Thanks to their unique structure and heat transfer efficiency, these systems offer outstanding durability and cost-effectiveness.

Introduction to Thermal Oil Heater Systems

A thermal oil heater is a specialized industrial heating system designed to transfer heat indirectly using heat transfer oil instead of water or steam. This method offers stable high-temperature operation without the pressure risks associated with steam-based systems.

Unlike a traditional steam boiler, a thermal oil boiler operates at low pressure while achieving high thermal output, making it safer and more energy-efficient. This system is widely used in industries like chemical processing, textile dyeing, food production, and plastic manufacturing, where precise and continuous heating is required.

Why choose thermal oil over steam?

The structure of a thermal oil heater allows for uniform heat distribution, minimal heat loss, and extended equipment lifespan. Because it avoids water scaling and pressure buildup, maintenance is significantly reduced.

Entity Comparison – Heat Transfer Oil vs. Steam/Water:

-

Thermal oil can reach up to 320°C without the need for pressurization.

-

In contrast, steam systems must operate at high pressure to deliver similar temperatures.

Understanding how a thermal oil heater works helps factories optimize both safety and fuel efficiency, making it a smart long-term investment for high-precision heating applications.

Structure of a Thermal Oil Heater

The structure of a thermal oil heater is engineered for efficient heat transfer, safety, and long-term durability. Each component plays a critical role in ensuring that the system operates smoothly under high temperatures with minimal maintenance.

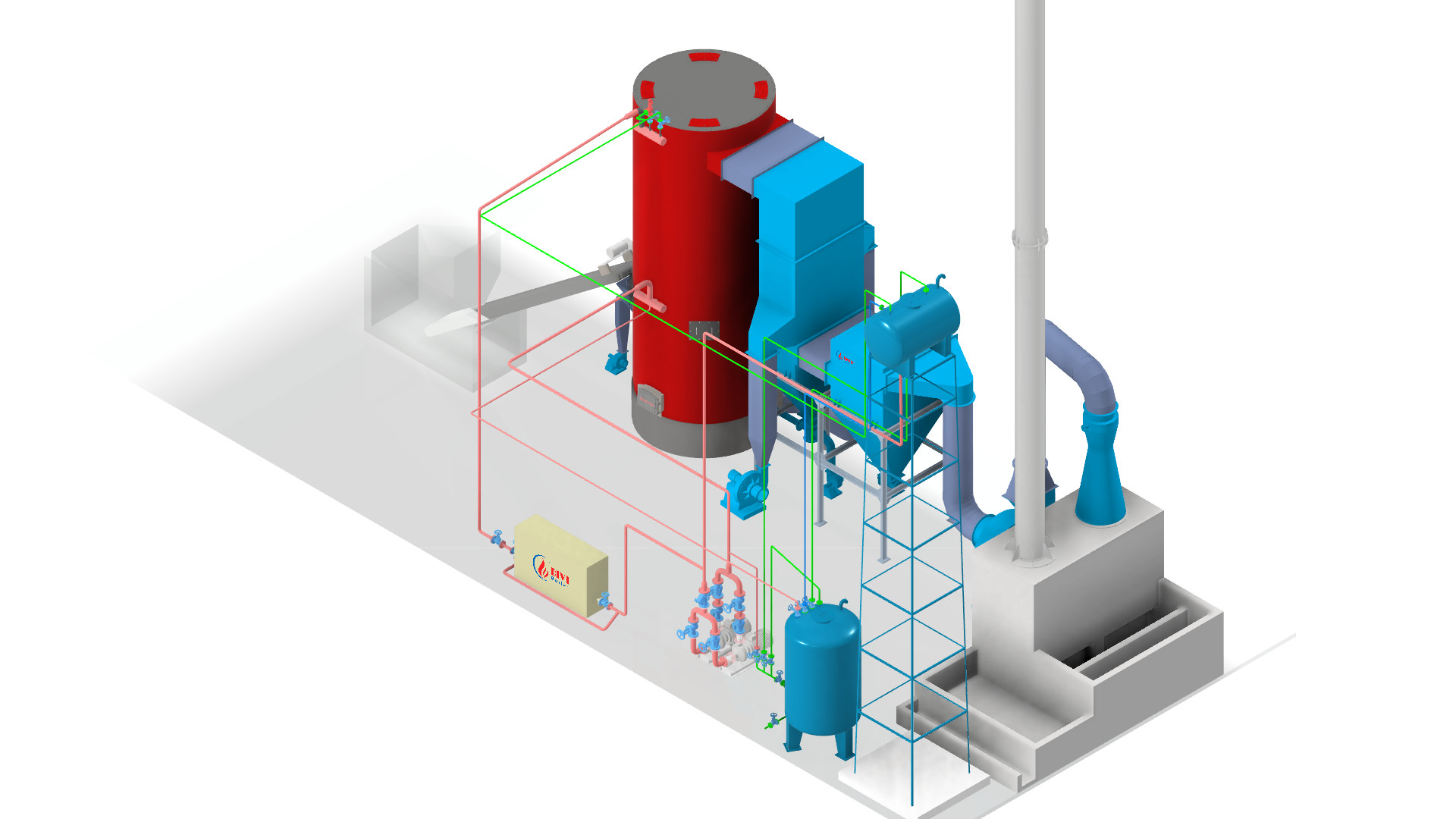

Thermal oil heater structure overview

Thermal oil heater structure overview Oil Circulation System

One of the core parts of a thermal oil boiler is the oil circulation system, which includes:

-

Circulating pump

-

Expansion tank

-

Heat transfer oil pipelines

The circulating pump ensures continuous oil movement through the system. This allows the thermal oil heater to deliver steady and controlled heat to processing equipment. The expansion tank absorbs changes in oil volume as the temperature fluctuates, maintaining system balance and pressure.

Combustion chamber & heat exchange area

his section defines how a thermal oil heater works by transferring heat from the fuel combustion process to the oil.

Key components include:

-

Furnace tube

-

Radiation and convection sections

-

Flue gas outlet

Inside the combustion chamber, fuel is burned to heat coils that contain the circulating oil. The hot gases pass through radiant and convection surfaces, maximizing thermal absorption before exiting via the flue. This indirect heating method enhances efficiency and reduces the risk of direct flame contact with oil.

Visual Tip: Include a labeled cross-sectional diagram of the thermal oil heater showing the oil flow path, furnace tube, and exhaust system.

The precise structure of a thermal oil heater allows for safe, high-performance heating across various industrial applications, setting it apart from traditional systems.

Working Principle: How Does a Thermal Oil Heater Operate?

A thermal oil heater operates using a closed-loop system where heat transfer oil is heated indirectly and circulated through insulated pipelines. This oil then transfers heat to various industrial applications without undergoing phase change, ensuring consistent performance.

Unlike water-based systems, the thermal oil boiler maintains high-temperature at low pressure, minimizing operational risk while maximizing energy efficiency. This principle is essential to understanding how thermal oil heater works in demanding environments such as chemical processing or food production.

Comparison with Steam Boiler Operation

| Feature | Thermal Oil Heater | Steam Boiler |

|---|---|---|

| Pressure | Low-pressure operation | High pressure required |

| Max temperature | Up to 320°C | Typically below 200°C |

| Risk of explosion | Minimal | Higher risk |

| Maintenance | Less frequent, more cost-effective | Requires frequent inspections |

This comparison highlights the superior structure of a thermal oil heater, especially in terms of safety and maintenance. Its indirect heating mechanism and closed-loop operation make it a reliable solution for long-term industrial use.

Key advantages of Thermal Oil Heaters

Choosing a thermal oil heater over traditional steam systems offers numerous operational and financial benefits. These advantages stem from its closed-loop structure, unique indirect heating mechanism, and the way thermal oil boilers manage energy distribution. Main benefits:

- Lower maintenance costs: No water treatment is needed, reducing scale buildup and service interruptions.

- High thermal efficiency: Up to 90% efficiency, thanks to consistent heat transfer and minimal energy loss.

- Stable temperature control: Operates without pressure fluctuations, enhancing process safety and product quality.

- Fuel flexibility: Compatible with diesel, natural gas, and biomass, allowing adaptation to local fuel resources.

Use cases across industries:

The structure of thermal oil heaters makes them ideal for sectors that require continuous and controlled high-temperature heat:

| Industry | Application |

|---|---|

| Textile | Dyeing machines, drying units |

| Food Processing | Cooking vessels, sterilization lines |

| Petrochemical | Distillation columns, reactors |

Tip: Include a pie chart showing industry distribution using thermal oil boilers to enhance visual engagement and fulfill entity-based topic coverage.

These benefits, combined with the advanced structure of a thermal oil heater, make it a preferred solution for manufacturers seeking safety, savings, and high performance.

Safety Considerations in Thermal Oil Heater Usage

While a thermal oil heater is designed for safe operation, proper system design and regular maintenance are essential to minimize risk.

Common safety concerns

Even with the advanced structure of a thermal oil heater, certain issues may arise if not properly monitored:

-

Overheating of the oil due to faulty temperature control

-

Oil leakage from worn seals or loose connections

-

Pump failure, which can interrupt the closed-loop circulation and cause system imbalance

These risks are less frequent than in high-pressure systems, but they must still be addressed proactively.

How to prevent overheating or leakage

To ensure the long-term safety of a thermal oil boiler, follow these best practices:

-

Install temperature sensors and limiters: These devices prevent thermal overload by automatically shutting down the heater at unsafe levels.

-

Use expansion tanks: They absorb volume changes in the heat transfer oil, maintaining pressure stability across the system.

-

Schedule regular inspections: Check pumps, valves, and pipe integrity to detect signs of wear before failure occurs.

Understanding how a thermal oil heater works allows plant operators to implement the right safety mechanisms and prevent downtime. With the proper setup, a thermal oil system can run 24/7 with minimal risk.

Choosing the right Thermal Oil Heater for your factory

Selecting the right thermal oil heater depends on several technical and operational factors. A well-matched system improves safety, energy efficiency, and long-term performance across industrial applications.

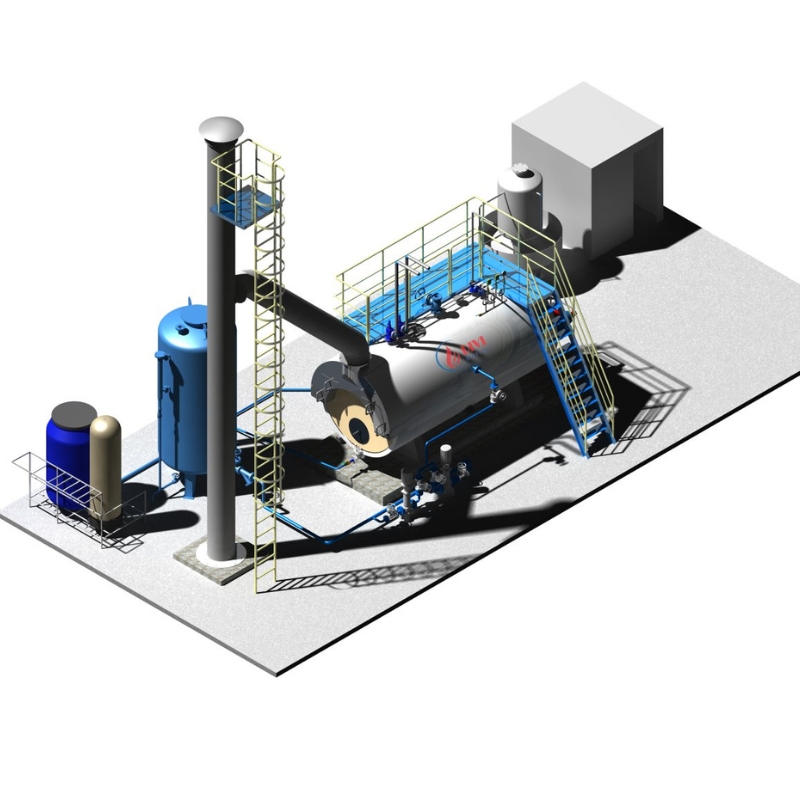

Thermal oil heater installed in factory setup

Thermal oil heater installed in factory setupKey factors to consider

Before investing in a thermal oil boiler, evaluate the following:

-

Required heat capacity: Determine your demand in kcal/h or kW to size the heater properly.

-

Fuel source availability: Ensure compatibility with on-site fuel (gas, diesel, biomass).

-

Emission regulations: Select a model that meets local environmental standards.

Choosing the appropriate system starts with understanding how thermal oil heater works and how it fits your production flow. The structure of thermal oil heater should also align with your layout constraints and integration requirements.

Thermal Oil Heater vs. Steam Boiler: Which one to choose?

When deciding between a thermal oil heater and a traditional steam boiler, it’s important to compare performance, safety, and long-term costs. Understanding the differences helps determine how thermal oil heater works better in specific industrial applications.

The structure of a thermal oil heater minimizes risks by avoiding direct contact with water or steam. Unlike steam systems, it doesn’t require pressurized vessels or frequent inspections, making it ideal for long-running processes.

FAQ – Thermal Oil Heaters

1. What is the maximum temperature a thermal oil heater can reach?

A thermal oil heater can reach up to 320°C (608°F) when operated with specialized heat transfer fluids. This makes it suitable for high-temperature processes that cannot be handled by traditional steam systems.

2. How often should the thermal oil be replaced?

In a properly maintained thermal oil boiler, the oil should typically be replaced every 1–2 years, depending on operating hours and the condition of the fluid. Regular testing ensures the structure of thermal oil heater operates safely and efficiently.

3. Can thermal oil heaters work in explosive environments?

Yes. A thermal oil heater can be used in hazardous zones if equipped with ATEX-certified enclosures, explosion-proof components, and compliant system design.

4. What fuel types are compatible?

Most modern thermal oil boilers support a wide range of fuels, including diesel, natural gas, LPG, wood chips, and biomass—enhancing flexibility and energy cost optimization.

5. Is a thermal oil heater suitable for continuous 24/7 operation?

Absolutely. The closed-loop design and indirect heating method in how thermal oil heater works makes it highly reliable for round-the-clock industrial use with minimal downtime.

Conclusion: Why Thermal Oil Heaters are the Smart Investment:

Thanks to their low-pressure operation, high-temperature stability, and minimal maintenance requirements, a thermal oil heater has become the preferred solution for modern industrial heating systems. Unlike traditional steam setups, the structure of a thermal oil heater allows for indirect heating without the risks of pressure explosions or scaling.

Whether you're managing a textile plant, food processing facility, or chemical production line, understanding how thermal oil heater works can help optimize safety, efficiency, and operational uptime.

With superior energy performance, high adaptability across fuel types, and proven durability, a thermal oil boiler represents a long-term investment that delivers measurable ROI.

Contact DIVI Group today to receive a personalized consultation or request a custom quote tailored to your factory’s requirements.

Related Articles:

Additional Reference Videos:

8M kcal/h Biomass Thermal Oil Furnace – Cut Costs, Maximize Efficiency

[DIVI] Biomass-fired thermal oil boiler: a mystery unveiled

DIVI Group's Boiler Products:

Other news

-

Steam Separator – An Effective Solution for Dry Steam

29/12/2025, -

Treating High CO Emissions in Fixed-Grate Boilers – Is Boiler Replacement Necessary? Practical Solutions from DIVI

18/12/2025, -

What Is a Steam Trap? Principles, Types, and How to Select the Right Steam Trap for Your Steam System

07/12/2025, -

COMPARISON OF STEAM TRAPS: PRINCIPLES – EXPERIMENTS – OPTIMAL SELECTION FOR STEAM SYSTEMS

29/11/2025, -

Compact Biomass-Fired Boiler DVG-VN – The Optimal Fossil-Fuel Replacement Solution for Factories

23/11/2025, -

Which Boiler Should You Choose: Fixed Grate or Fluidized Bed? Detailed Efficiency, Cost & Environmental Comparison

24/06/2025, -

5 Common Mistakes in Industrial Steam Distribution Systems

11/06/2025, -

Mr. Boiler Speaks: Wake-Up Call from an Industrial Icon

09/06/2025, -

3 Danger Signs of Boiler Operation You Should Never Ignore

24/05/2025, -

7 Common Causes of Boiler Flue Gas Issues – Effective Treatment Solutions

08/05/2025,

EN

EN