What is the Working Principle of a Two-Drum Water-Tube Biomass Fluidized Bed Boiler?

What exactly is a fluidized bed boiler and how does the 2-balloon fluidized bed boiler improve energy production? If you're considering advanced boiler systems for energy generation, this article will delve into the 2-balloon fluidized bed boiler's design, operational principle, benefits, and limitations. Stay tuned as we explore how this boiler system works and why it’s a top choice for industries seeking efficiency and sustainability.

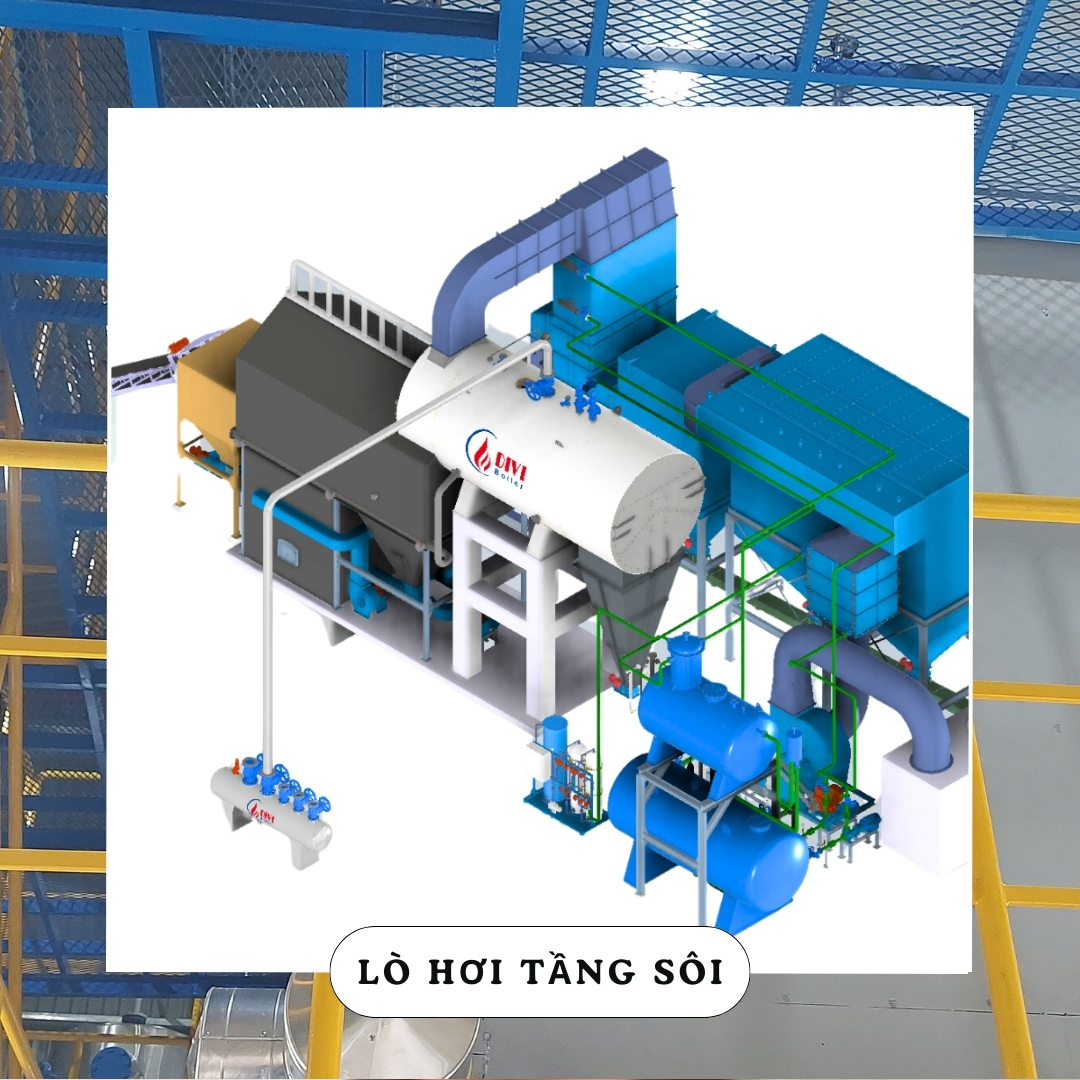

What is a Fluidized Bed Boiler?

Biomass Fluidized Bed Boilers

Biomass Fluidized Bed BoilersA fluidized bed boiler (FBB) is a type of boiler system that uses a bed of solid particles (often sand or ash) suspended in a stream of fluidizing gas to burn fuel efficiently. Unlike traditional boilers, which burn fuel in a fixed or moving bed, the fluidized bed allows for better combustion by ensuring that all fuel particles are exposed to heat and oxygen. This design leads to improved efficiency and lower emissions, making fluidized bed boilers a great choice for sustainable energy production.

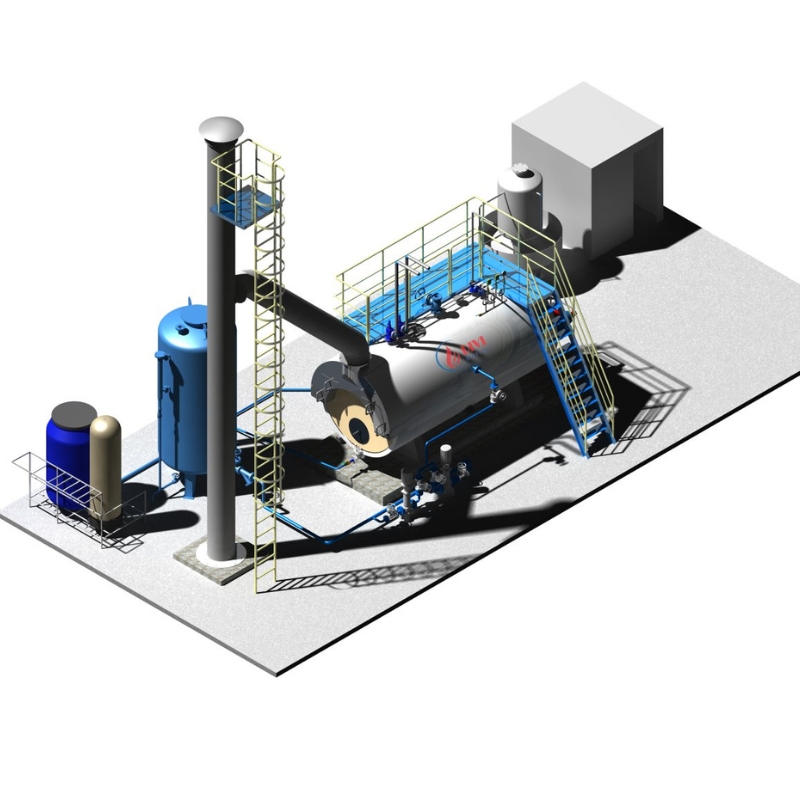

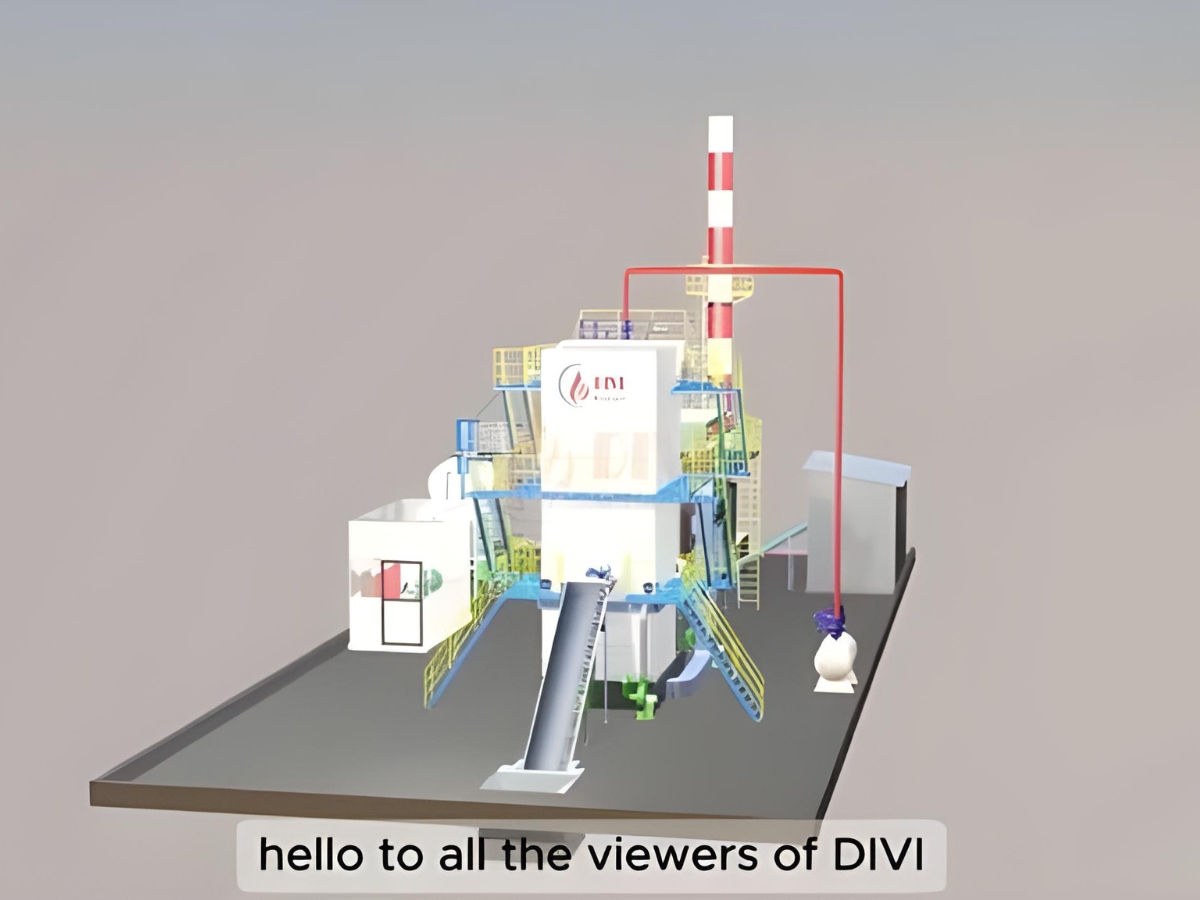

Structure of the 2-Balloon Fluidized Bed Boiler

The 2-balloon fluidized bed boiler is a sophisticated design that integrates two primary balloon-shaped structures for enhanced combustion and heat exchange efficiency. These structures are strategically placed within the system to optimize the flow of gas and particles, ensuring maximum heat transfer.

-

Primary Balloon (Fluidization Balloon): This is the core of the system where the fluidizing gas enters and causes the solid particles (such as sand) to "float," creating a fluid-like bed. This helps achieve uniform heating across the fuel bed, improving combustion efficiency.

-

Secondary Balloon (Heat Exchange Balloon): Positioned near the primary balloon, this second balloon assists in further refining the heat exchange process. The design of this balloon ensures that the heat generated in the combustion zone is efficiently transferred to the water or steam, increasing the overall thermal efficiency of the system.

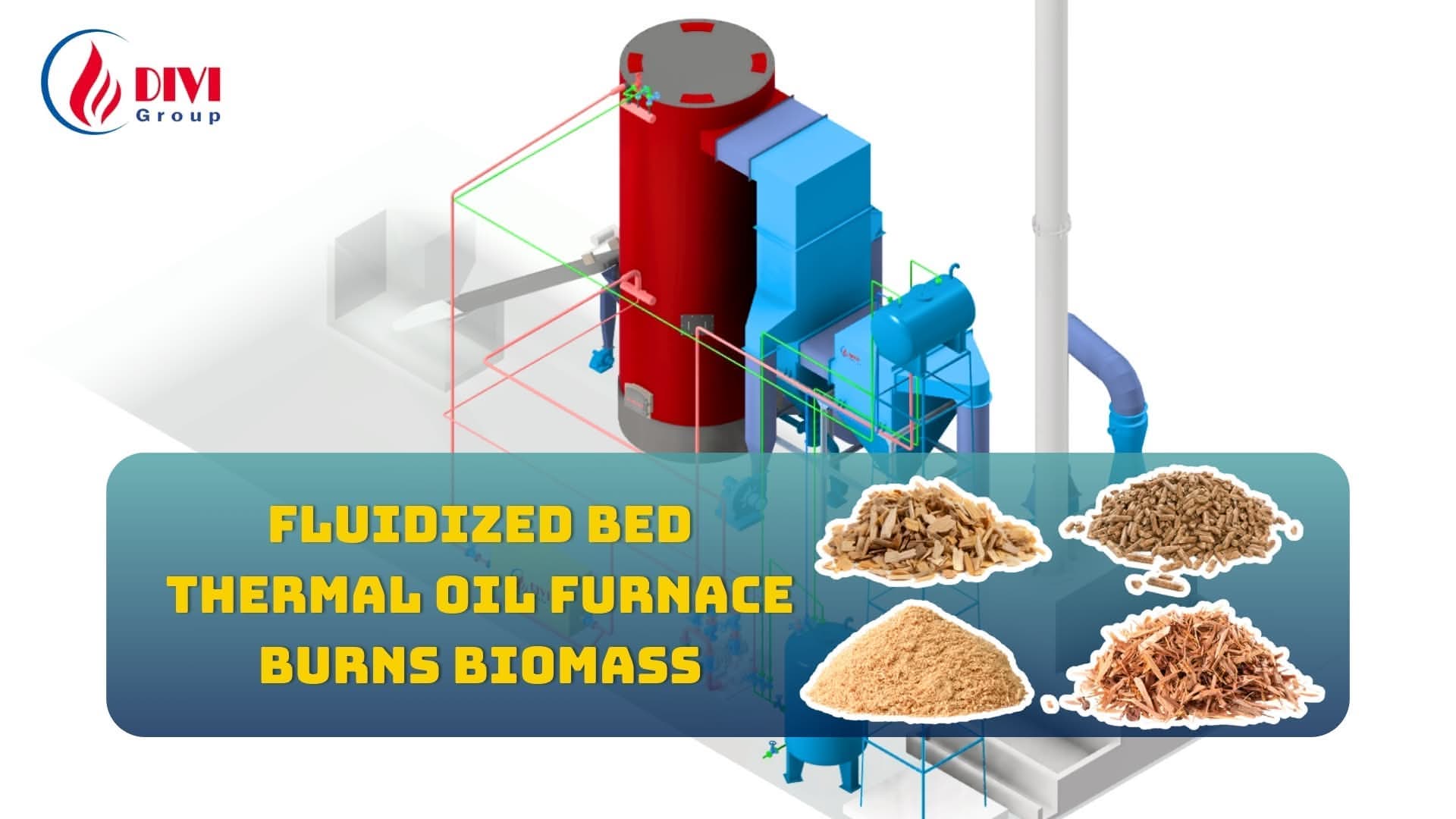

The 2-balloon fluidized bed boiler's design improves fuel burning, heat recovery, and reduces harmful emissions, which is ideal for industries using biomass fuels such as rice husks, wood chips, or agricultural residues.

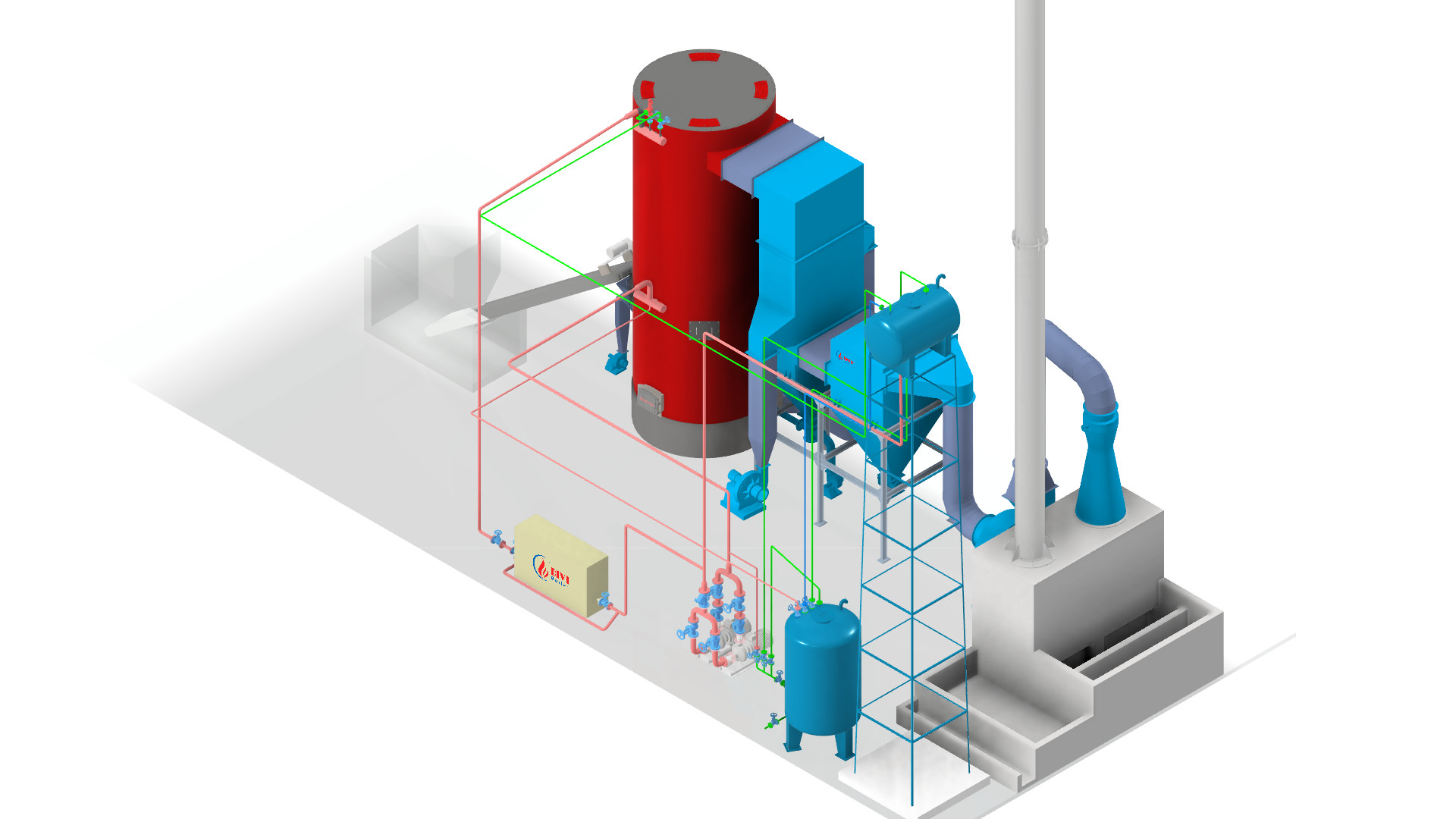

2 Balloon Fluidized Bed Boiler

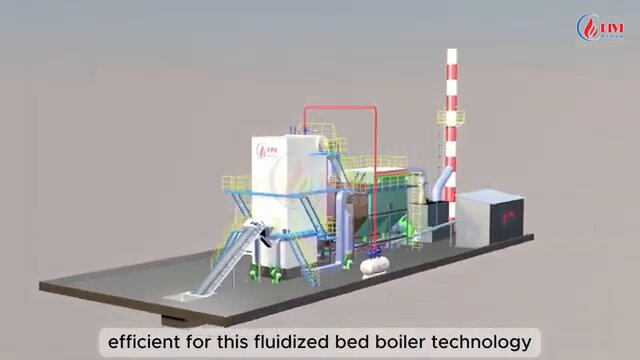

2 Balloon Fluidized Bed BoilerPrinciple of Operation of the 2-Balloon Fluidized Bed Boiler

The operation of the 2-balloon fluidized bed boiler is a fine-tuned process that combines advanced fluid dynamics and thermal engineering. Here's how it works:

-

Fuel Introduction: Biomass fuel or coal is introduced into the hopper where it is fed into the primary balloon. In this area, the fuel is subjected to intense heat and oxygen from the air supply system, ensuring a complete combustion process.

-

Fluidization Process: Air is blown into the fluidization balloon, causing the solid particles to fluidize. This creates a highly efficient combustion environment by ensuring that every fuel particle is uniformly heated and exposed to oxygen.

-

Combustion and Heat Transfer: The heat generated by combustion rises into the secondary balloon where it is absorbed by water circulating within the heat exchange system. This transfer of heat helps convert water into steam, which can then be used for industrial processes or electricity generation.

-

Flue Gas Management: The flue gases, after passing through the combustion and heat exchange zones, flow into a system designed to capture and reduce particulate emissions, ensuring that the 2-balloon fluidized bed boiler operates in an environmentally friendly manner.

This combination of fluidization and dual-balloon design optimizes energy efficiency while minimizing environmental impact, making it an excellent choice for industries looking to reduce their carbon footprint.

Advantages and Limitations of the 2-Balloon Fluidized Bed Boiler

Advantages and Limitations of the 2-Balloon Fluidized Bed Boiler

Advantages and Limitations of the 2-Balloon Fluidized Bed Boiler

Advantages of the 2-Balloon Fluidized Bed Boiler:

- Higher Efficiency: The fluidization process ensures that fuel is completely combusted, improving thermal efficiency.

- Lower Emissions: By maintaining optimal combustion conditions, this boiler design significantly reduces emissions such as CO2 and NOx, making it environmentally friendly.

- Flexibility in Fuel Use: It can burn a variety of fuels, including biomass, waste products, and traditional coal, making it versatile for different industrial needs.

- Enhanced Heat Recovery: The two-balloon design optimizes the heat exchange process, leading to better energy recovery and reduced fuel consumption.

Limitations of the 2-Balloon Fluidized Bed Boiler:

- Complex Design: The dual-balloon system and fluidized bed require careful design and maintenance, which can increase initial setup costs.

- Higher Operational Costs: While the system is efficient, it may require more sophisticated controls and monitoring, leading to higher operational expenses.

- Sensitivity to Fuel Type: While the boiler can handle various fuels, it works best with consistent, high-quality fuel types. Variations in fuel quality may affect performance.

Frequently Asked Questions (Q&A)

1. What is the main difference between a traditional boiler and a fluidized bed boiler?

A traditional boiler uses fixed or moving beds for combustion, whereas a fluidized bed boiler suspends fuel particles in a stream of air for more efficient and even combustion.

2. Can the 2-balloon fluidized bed boiler burn biomass?

Yes, the 2-balloon fluidized bed boiler is designed to burn a wide range of fuels, including biomass such as wood chips, rice husks, and agricultural waste.

3. What are the main environmental benefits of the 2-balloon fluidized bed boiler?

The system significantly reduces emissions, including CO2 and NOx, through efficient combustion and heat recovery.

4. How does the dual-balloon design improve efficiency?

The secondary balloon optimizes heat exchange, ensuring that the heat generated during combustion is efficiently transferred to the water or steam, improving overall system efficiency.

Conclusion: Is the 2-Balloon Fluidized Bed Boiler Right for You?

The 2-balloon fluidized bed boiler offers exceptional advantages in terms of energy efficiency, emissions control, and versatility in fuel usage. Its sophisticated design, which includes two fluidized balloons, enhances both combustion and heat exchange processes. For industries looking to switch to a more sustainable and efficient boiler system, this model is an excellent choice. However, it's essential to weigh the initial investment and operational complexities before deciding if it's the best fit for your needs.

If you're interested in exploring this technology further, DIVI Group can provide tailored solutions to meet your energy needs, ensuring the utmost in efficiency and sustainability.

Related Articles:

Additional Reference Videos:

[DIVI] Reveal interesting things from steam boilers from the steam room for newcomerse

[DIVI] Boiler safety and practices for safe operation

DIVI Group's Boiler Products:

Other news

-

Steam Separator – An Effective Solution for Dry Steam

29/12/2025, -

Treating High CO Emissions in Fixed-Grate Boilers – Is Boiler Replacement Necessary? Practical Solutions from DIVI

18/12/2025, -

What Is a Steam Trap? Principles, Types, and How to Select the Right Steam Trap for Your Steam System

07/12/2025, -

COMPARISON OF STEAM TRAPS: PRINCIPLES – EXPERIMENTS – OPTIMAL SELECTION FOR STEAM SYSTEMS

29/11/2025, -

Compact Biomass-Fired Boiler DVG-VN – The Optimal Fossil-Fuel Replacement Solution for Factories

23/11/2025, -

Which Boiler Should You Choose: Fixed Grate or Fluidized Bed? Detailed Efficiency, Cost & Environmental Comparison

24/06/2025, -

5 Common Mistakes in Industrial Steam Distribution Systems

11/06/2025, -

Mr. Boiler Speaks: Wake-Up Call from an Industrial Icon

09/06/2025, -

What is a Thermal Oil Heater? Structure, Benefits & Safety Tips

27/05/2025, -

3 Danger Signs of Boiler Operation You Should Never Ignore

24/05/2025,

EN

EN