The Benefits of a Deaerator Tank for Boiler Systems: Why Invest in One?

DIVI’ll dive into a crucial topic that may seem a bit technical but is extremely important for anyone working with boilers and industrial systems: the benefits of a deaerator tank in boiler systems. Have you ever wondered why factories invest in deaerator tanks? Let’s explore this topic with Divi Group and uncover all the answers.

What is a Deaerator Tank and Why is It Important?

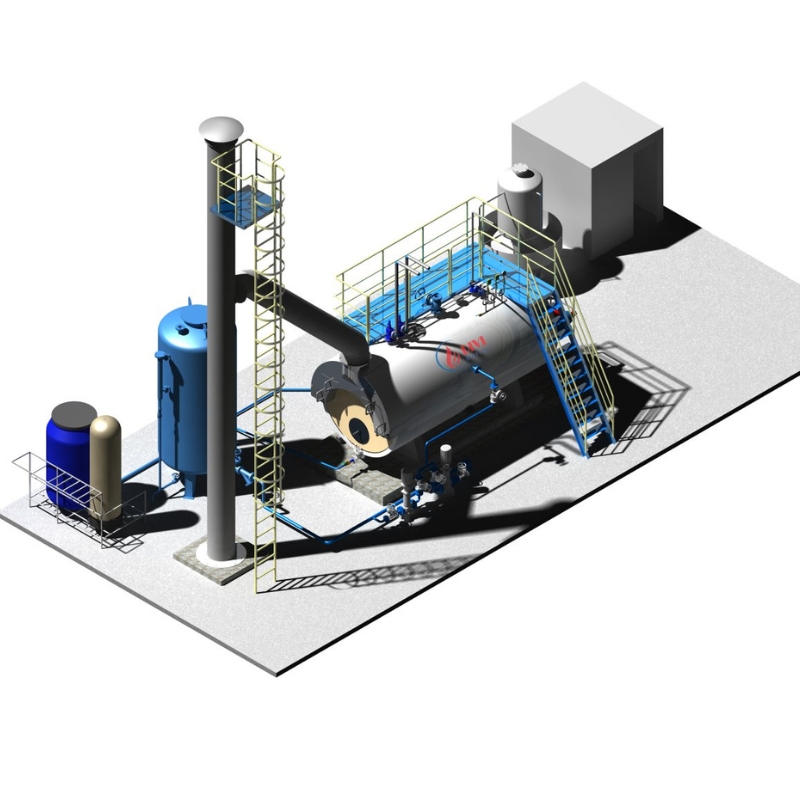

What is a deaerator tank

What is a deaerator tankBefore we discuss the advantages, let’s first understand what a deaerator tank is and why it plays such a pivotal role in boiler systems. A deaerator is a piece of equipment used to remove dissolved gases—mainly oxygen (O₂) and carbon dioxide (CO₂)—from the feed water supplied to boilers. It may sound complex, but it’s actually quite simple.

If water contains dissolved gases, these gases can cause corrosion to the metal components of the boiler system, reducing both the lifespan and efficiency of the equipment. A common analogy is seeing a bicycle exposed to the elements over time—rust develops due to the interaction between metal, air, and moisture. This corrosion in boilers happens similarly if the dissolved gases aren’t removed. A deaerator tank effectively addresses this issue, preventing corrosion and ensuring stable operations.

2. Benefits of a Deaerator Tank for Boilers

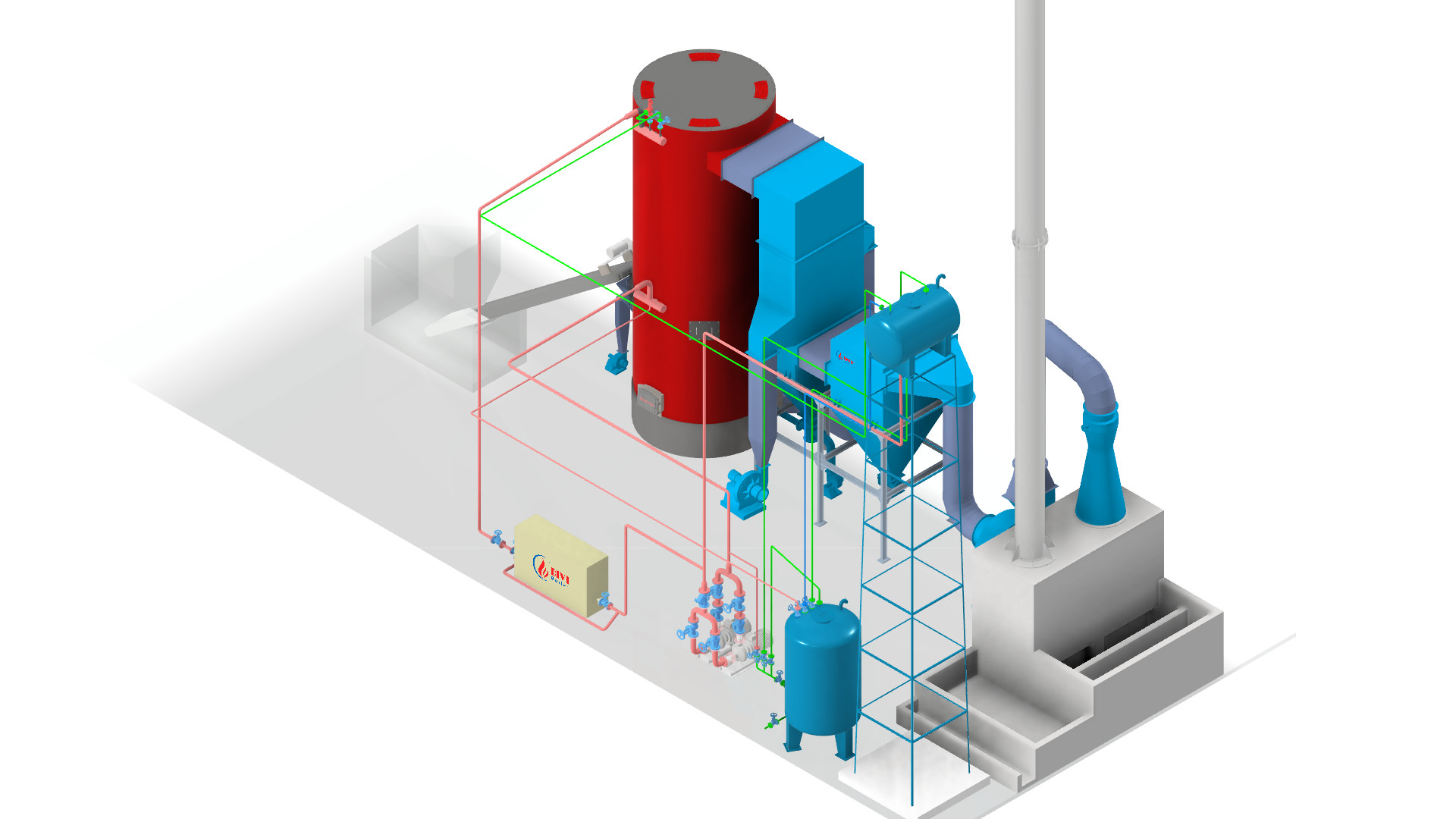

Increasing the Lifespan of the Boiler

The most notable benefit of a deaerator tank is that it extends the life of the boiler. As mentioned earlier, gases like oxygen and CO₂ are the main culprits causing corrosion in the boiler's metal parts. Corrosion not only reduces the quality of the equipment but also leads to frequent breakdowns, increasing repair and maintenance costs.

It’s similar to how you take care of your home by repainting the walls when the paint starts to peel. Removing dissolved gases helps prevent corrosion before it becomes a major issue. Therefore, the deaerator tank is not only a protective device but also a tool to reduce maintenance costs and extend the lifespan of the entire boiler system.

Deaerator tank helps increase boiler life

Deaerator tank helps increase boiler lifeFuel Savings and Cost Optimization

Deaerators help Fuel Savings

Deaerators help Fuel SavingsIn addition to protecting the boiler from corrosion, the deaerator tank has another significant benefit: it helps save fuel. By removing dissolved gases from the water, the heating process in the boiler becomes faster and more efficient. This means you need less fuel to heat the water and produce steam – which ultimately reduces operational costs.

Think of it as boiling water on a gas stove: if the water is already warm, you’ll need less time and energy to bring it to a boil compared to starting with cold water. The same principle applies to boilers. By removing dissolved gases, you will save a substantial amount of fuel.

Maintaining Stable Performance

Another major benefit of the deaerator tank is that it helps maintain consistent boiler performance. When water free of dissolved gases enters the boiler, the steam generation process runs more smoothly. This helps maintain stable pressure inside the boiler, ensuring that the system does not lose performance during operation.

Imagine driving a car on a smooth, stable road – the car maintains a steady speed. But if you encounter a bumpy road, the car slows down and takes time to pick up speed again. The deaerator tank ensures that your boiler system operates at optimal efficiency, avoiding unexpected performance dips.

Deaerator Helps Maintaining Stable Performance

Deaerator Helps Maintaining Stable PerformanceConclusion

Using a deaerator tank not only extends the lifespan of your boiler but also saves fuel and maintains the stability of the entire system. If you are considering investing in a boiler system, remember that a high-quality deaerator tank will help protect and optimize the entire operational process.

We hope this article has provided a comprehensive overview of the importance of deaerators in industrial systems. If you have any further questions, feel free to leave a comment or contact us for more advice!

Related Articles:

Additional Reference Videos:

[DIVI] 2 Simple Steps For Operating A Boiler Safely

[DIVI] 5 Basic steps to reduce fuels consumption for Boilers

DIVI Group's Boiler Products:

Other news

-

Steam Separator – An Effective Solution for Dry Steam

29/12/2025, -

Treating High CO Emissions in Fixed-Grate Boilers – Is Boiler Replacement Necessary? Practical Solutions from DIVI

18/12/2025, -

What Is a Steam Trap? Principles, Types, and How to Select the Right Steam Trap for Your Steam System

07/12/2025, -

COMPARISON OF STEAM TRAPS: PRINCIPLES – EXPERIMENTS – OPTIMAL SELECTION FOR STEAM SYSTEMS

29/11/2025, -

Compact Biomass-Fired Boiler DVG-VN – The Optimal Fossil-Fuel Replacement Solution for Factories

23/11/2025, -

Which Boiler Should You Choose: Fixed Grate or Fluidized Bed? Detailed Efficiency, Cost & Environmental Comparison

24/06/2025, -

5 Common Mistakes in Industrial Steam Distribution Systems

11/06/2025, -

Mr. Boiler Speaks: Wake-Up Call from an Industrial Icon

09/06/2025, -

What is a Thermal Oil Heater? Structure, Benefits & Safety Tips

27/05/2025, -

3 Danger Signs of Boiler Operation You Should Never Ignore

24/05/2025,

EN

EN