Flue gas treatment in boilers is essential for environmental protection, public health, and regulatory compliance. By employing appropriate treatment methods and advanced technologies, industries can reduce harmful emissions and contribute to a cleaner, healthier environment.

Flue Gas Treatment Systems: Protecting Health and the Environment

Flue gas treatment in industrial boilers is not only a key concern for manufacturers but also a significant challenge for environmental sustainability and public health. Proper flue gas treatment is crucial for compliance with environmental laws and for safeguarding the health of the community. In this guide, we’ll explore the core areas of flue gas treatment: CO emission control, particulate recovery, and SOx minimization.

Why Flue Gas Treatment Matters

Flue gas treatment

Flue gas treatmentBoiler emissions contain harmful compounds like carbon monoxide (CO), sulfur oxides (SOx), and particulate matter, which pose serious risks if not managed effectively. Compliance with flue gas treatment regulations isn’t just a legal requirement; it’s a responsibility to the environment and to those affected by the air we breathe.

- CO Emissions can cause severe respiratory issues and restrict oxygen flow in the bloodstream.

- SOx Emissions contribute to acid rain and have damaging effects on water sources, soil, ecosystems, and public health.

- Particulate Matter is a health hazard, especially for vulnerable populations like children and the elderly, as it can penetrate deeply into the lungs and lead to cardiovascular and respiratory diseases.

Key Components in Flue Gas Treatment

To understand flue gas treatment, we must consider each pollutant:

- CO (Carbon Monoxide): CO forms during incomplete fuel combustion and is highly toxic. Without treatment, CO emissions can endanger communities.

- SOx (Sulfur Oxides): These compounds, including sulfur dioxide (SO2) and sulfur trioxide (SO3), lead to environmental harm through acid rain.

- Particulate Matter: Generated from fuel combustion, particulates require special filtration to prevent airborne spread and health impacts.

Flue gas treatment

Flue gas treatmentCO Emission Control: Challenges and Solutions

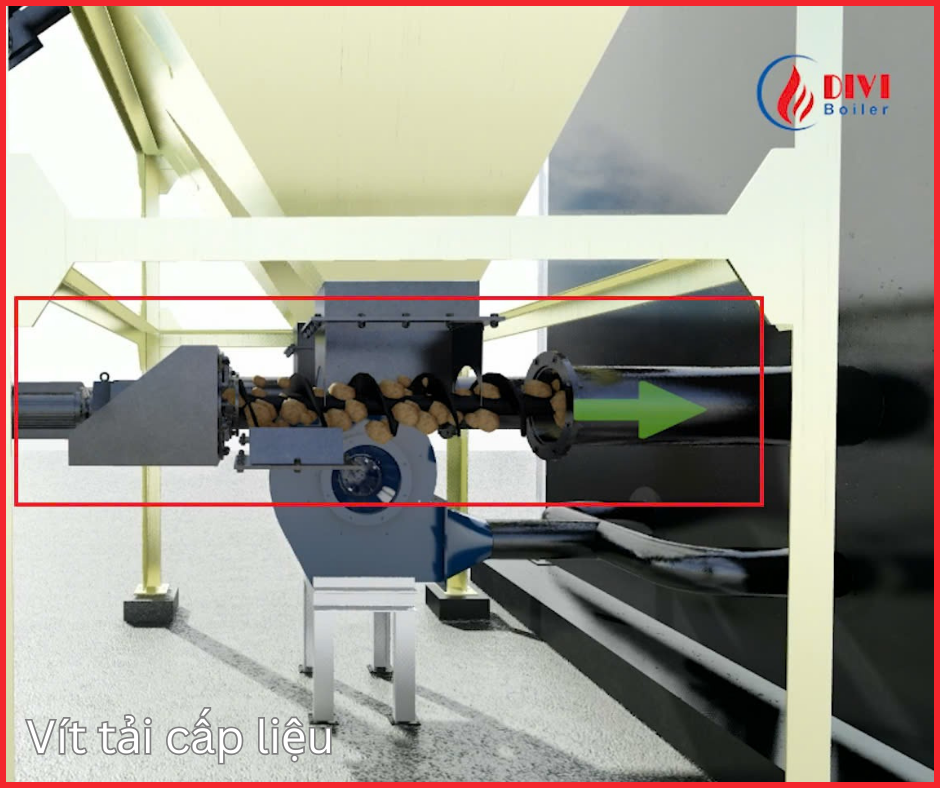

flue gas treatment - Fuel Load Utilization

flue gas treatment - Fuel Load UtilizationCO emissions are a primary focus in flue gas treatment because of their toxicity. The following are strategies to manage CO emissions effectively:

- Ensuring Complete Combustion: CO forms when combustion is incomplete, so it’s crucial to optimize the combustion process by controlling moisture levels in the fuel. Lower moisture allows for more complete burning and less CO formation.

- Fuel and Load Adjustment: Aligning fuel supply to load requirements helps stabilize combustion. An automated fuel and oxygen delivery system can maintain the optimal pressure and reduce CO output.

- Oxygen Regulation in Combustion: Balancing oxygen levels is essential; too little oxygen results in black smoke and increased CO, while too much leads to excess white smoke, which may still contain CO. Sensors and visual smoke assessment are effective tools for this adjustment.

Particulate Control and Recovery in Flue Gas Treatment

Particulates must be filtered to prevent environmental contamination. Common methods include:

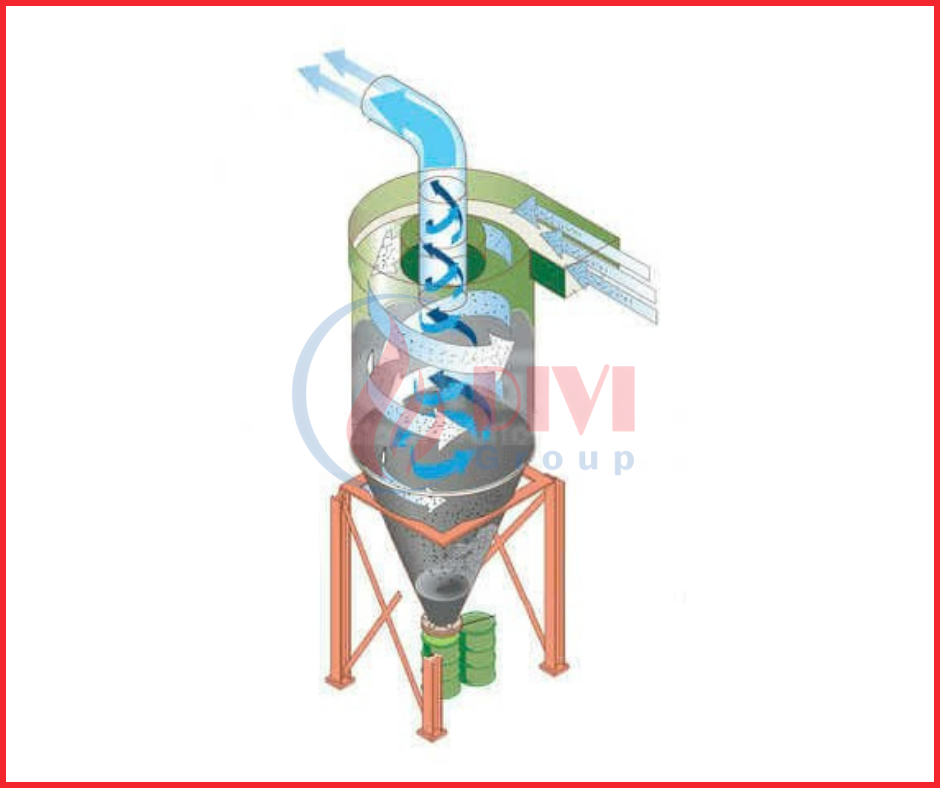

- Cyclone Dust Collection: This centrifugal system removes larger dust particles efficiently.

- Bag Filters: These filters offer nearly complete dust removal, although they require significant space and investment.

- Water Scrubbing: Water sprays help capture particulates but require water management to prevent white vapor from misleadingly signaling pollution.

Combining these methods can yield the most effective results based on industry needs and local regulations.

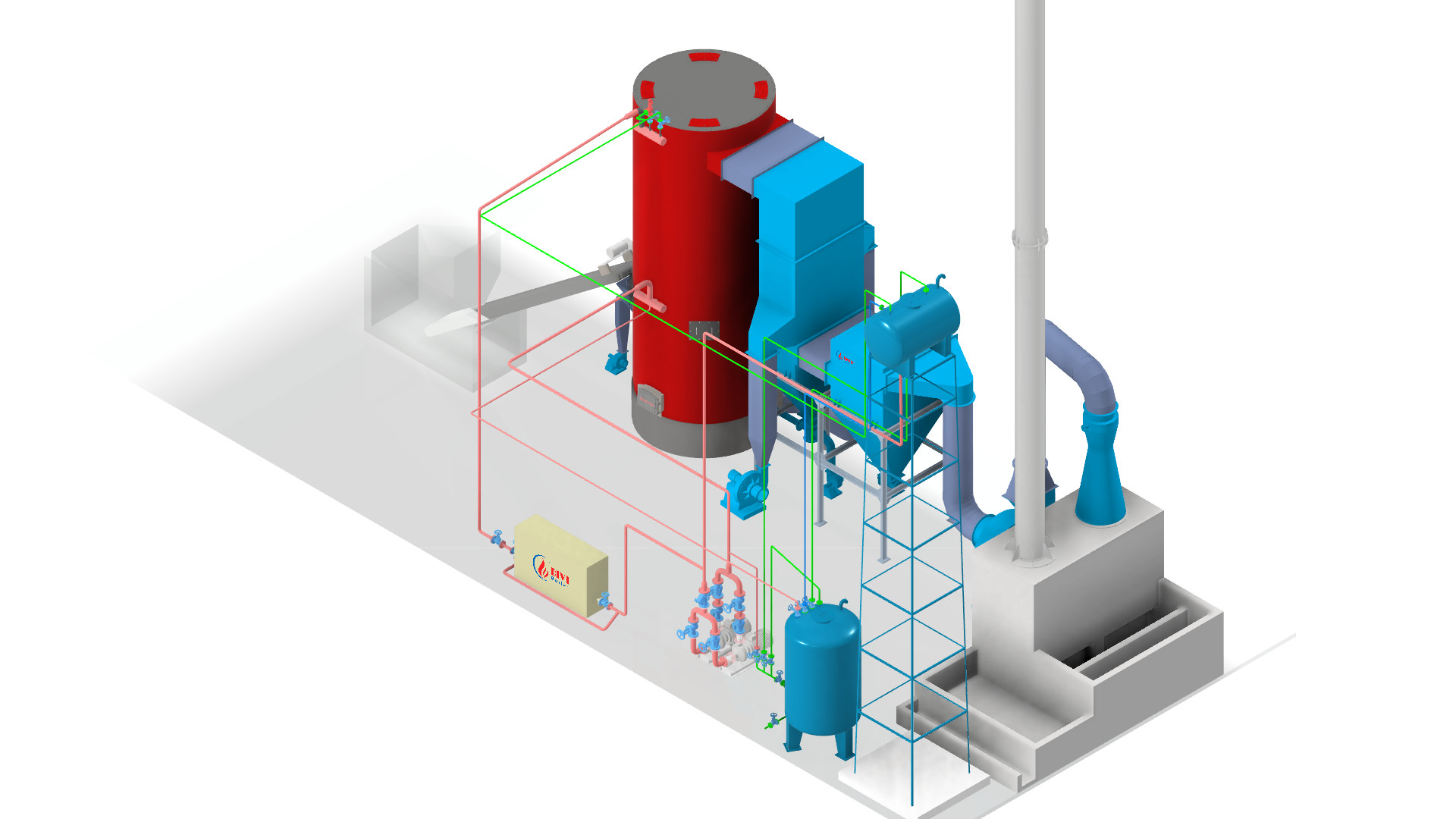

flue gas treatment - Cyclone Dust Filtration

flue gas treatment - Cyclone Dust FiltrationSOx Emission Reduction Techniques

flue gas treatment - SOx emissions

flue gas treatment - SOx emissionsSOx emissions, arising from sulfur-heavy fuels like FO oil and coal, are managed with systems that combine water scrubbing and alkaline solutions such as lime or sodium hydroxide. This interaction precipitates SOx compounds, enabling easier waste management and reducing emissions.

Frequently Asked Questions on Flue Gas Treatment

-

How can CO emissions be effectively reduced? CO can be minimized by controlling combustion conditions, including temperature and oxygen levels.

-

What are the best solutions for particulate recovery in industrial boilers? Cyclone collectors and bag filters offer efficient particulate removal. Cyclone is cost-effective, while bag filters ensure almost complete dust recovery.

-

What’s the most effective SOx treatment method? Water scrubbing is highly effective for SOx emissions, though other methods like dry scrubbing can also be applied based on specific plant needs.

-

What are the limitations of water scrubbing? This technique consumes water and can produce liquid waste, which requires treatment. The vapor may also appear as white smoke.

-

How can fossil fuel plants manage CO emissions? Advanced combustion technology and oxygen monitoring help reduce CO. Catalytic oxidation devices may also be implemented for higher safety.

Conclusion

Additional Reference Videos:

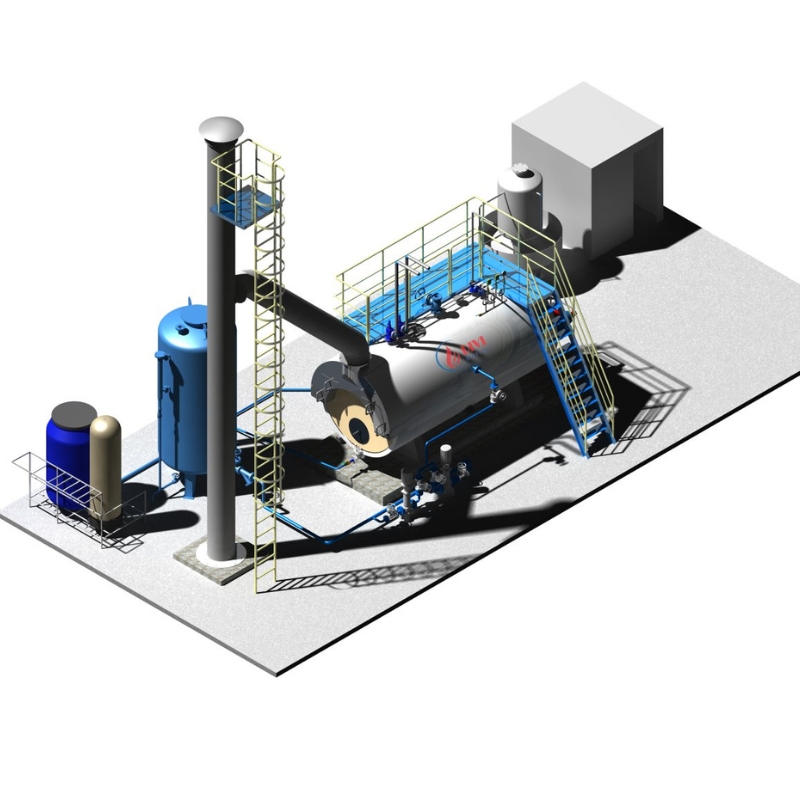

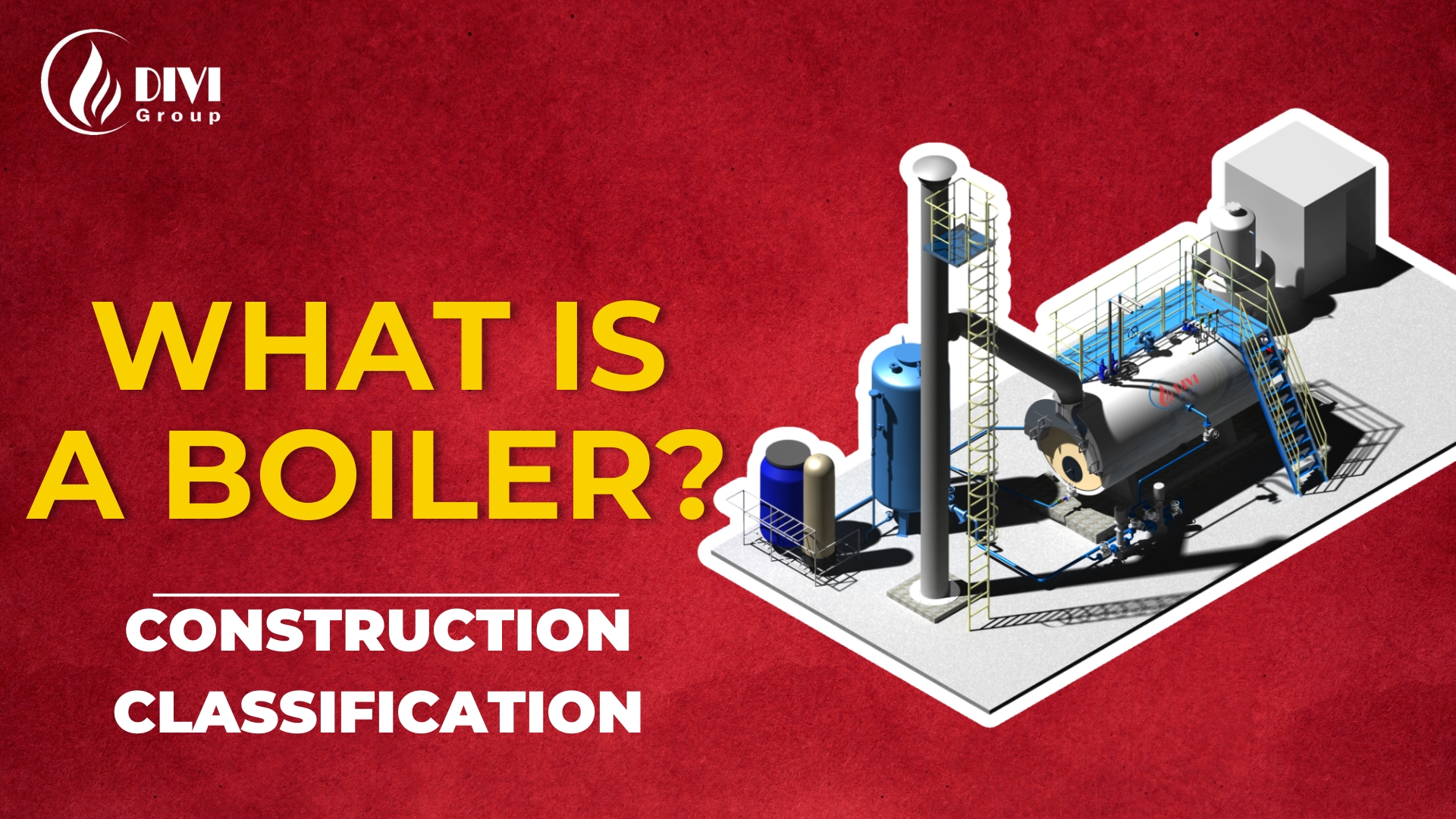

[DIVI] Reveal interesting things from steam boilers from the steam room for newcomerse

[DIVI] Unveiling steam boilers: understanding concepts, construction and classification

DIVI Group's Boiler Products:

Other news

-

Steam Separator – An Effective Solution for Dry Steam

29/12/2025, -

Treating High CO Emissions in Fixed-Grate Boilers – Is Boiler Replacement Necessary? Practical Solutions from DIVI

18/12/2025, -

What Is a Steam Trap? Principles, Types, and How to Select the Right Steam Trap for Your Steam System

07/12/2025, -

COMPARISON OF STEAM TRAPS: PRINCIPLES – EXPERIMENTS – OPTIMAL SELECTION FOR STEAM SYSTEMS

29/11/2025, -

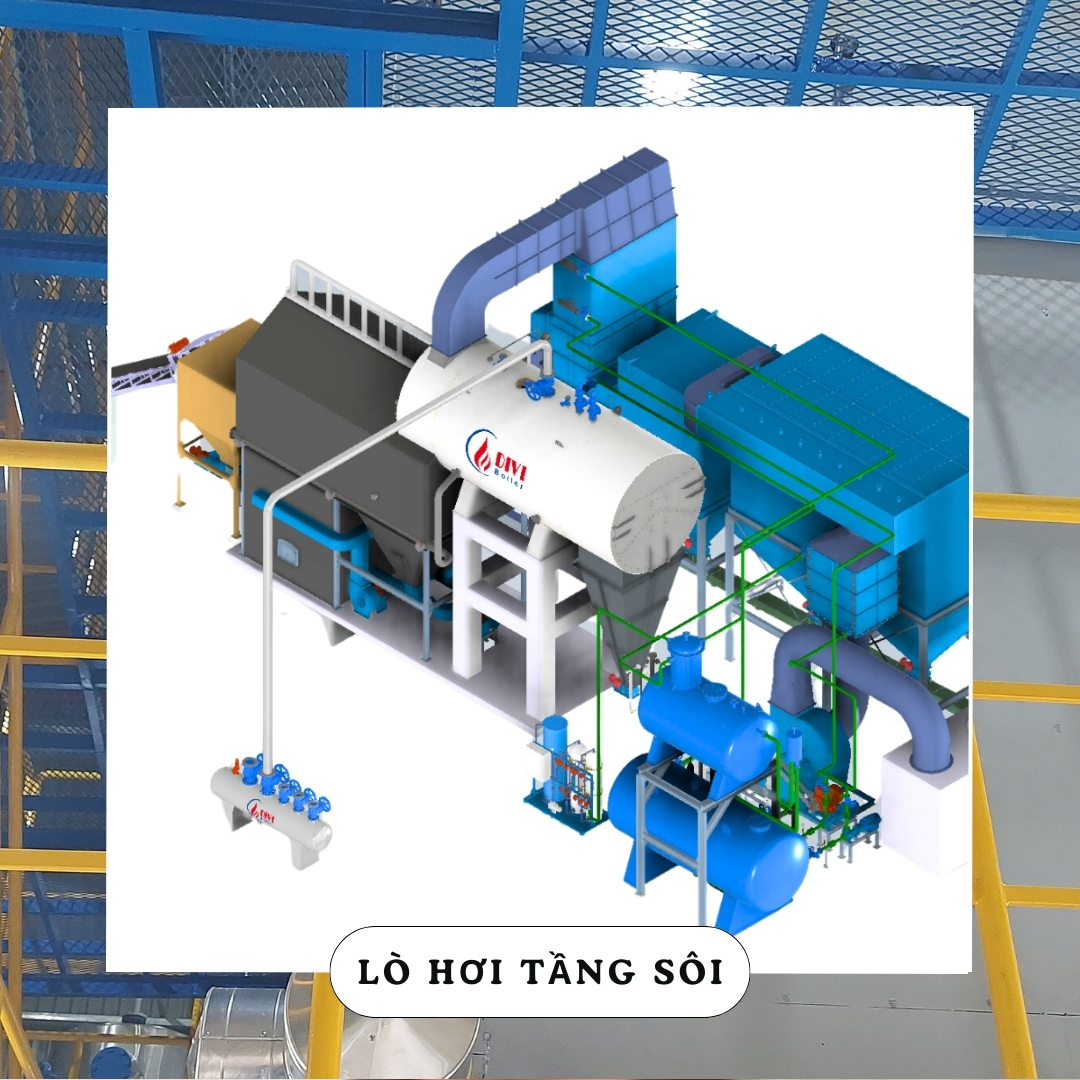

Compact Biomass-Fired Boiler DVG-VN – The Optimal Fossil-Fuel Replacement Solution for Factories

23/11/2025, -

Which Boiler Should You Choose: Fixed Grate or Fluidized Bed? Detailed Efficiency, Cost & Environmental Comparison

24/06/2025, -

5 Common Mistakes in Industrial Steam Distribution Systems

11/06/2025, -

Mr. Boiler Speaks: Wake-Up Call from an Industrial Icon

09/06/2025, -

What is a Thermal Oil Heater? Structure, Benefits & Safety Tips

27/05/2025, -

3 Danger Signs of Boiler Operation You Should Never Ignore

24/05/2025,

EN

EN