CENTRAL REGION BREWERY

-

Designing & creating

According to standards TCVN 7704 - 2007 & TCVN 12728 - 2019 -

Design pressure

12 bar

-

Power consumption

4 kW/ton of steam -

Boiler capacity

8 tons of steam/hour

-

Total amount of steam supplied

24,000 tons/year -

Fuel

Biomass

DETAILS DESCRIPTION

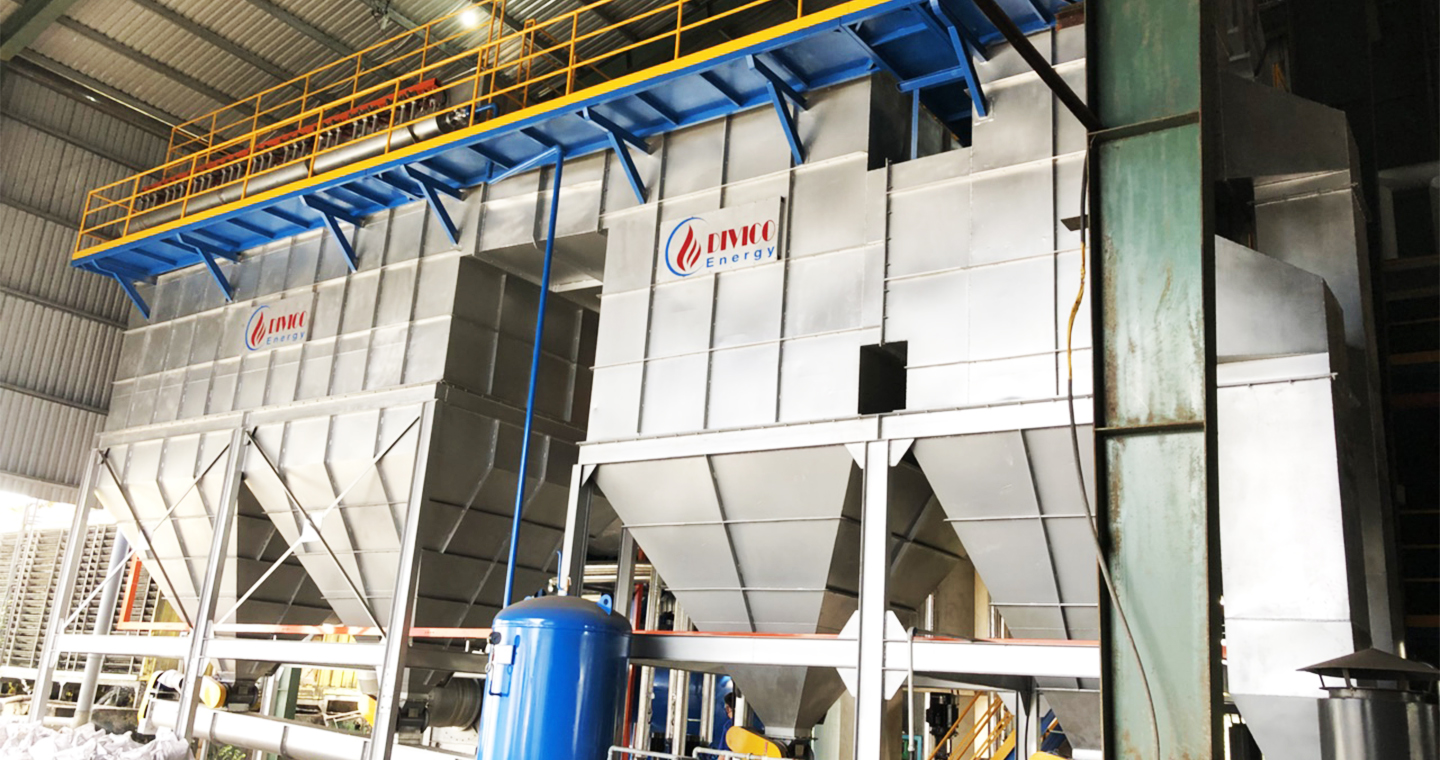

DIVI Group is honored to be entrusted with the contract for designing, installing, and transferring technology for the boiler system for Central Region Brewery, one of the leading breweries in the area. This project serves as a testament to DIVI Group's commitment to providing efficient and sustainable energy solutions to manufacturing enterprises.

Technical Features:

+ The boiler system is designed with a large capacity of up to 8 tons, utilizing fuel sources such as wood chips, pellets, and ground husks, all of which are renewable and environmentally friendly resources. The integration of fluidized bed boiler technology and high-quality standards such as TCVN 7704-2007 and TCVN 12728-2019 has created a safe and efficient operating system.

+ This boiler system has an annual steam output of up to 24,000 tons, with a design pressure of 12 bar. The energy consumption is also optimized, requiring only 4 kW per ton of steam, reducing operational costs and maximizing production efficiency.

Beer Production Line and Steam Utilization:

+ Central Region Brewery is equipped with an advanced production line encompassing essential steps from brewing, fermentation, filtration, to bottling and canning. In the beer production process, steam is a crucial element used in various stages.

Stages Requiring Steam in Beer Production:

1. Brewing: Steam is used to boil the raw material mixture such as barley and hops, creating wort for fermentation.

2. Fermentation: During the fermentation process, steam is utilized to maintain a stable temperature and create ideal conditions for microbial fermentation.

3. Filtration: Steam is also used in the filtration process to aid in separating and cleaning the beer from sediment.

4. Bottling and Canning: Lastly, steam is used in the bottling and canning process for sterilization and drying of the interior surfaces of bottles and cans before beer packaging.

Benefits and Impact:

DIVI Group's boiler project brings numerous benefits to Central Region Brewery.

+ The use of renewable fuels and advanced technology helps reduce costs and enhance production efficiency.

+ Moreover, utilizing steam in the beer production process ensures product quality and food safety.

Sustainable Commitment:

+ DIVI Group remains committed to supporting Central Region Brewery in optimizing their brewing process and ensuring a safe and sustainable working environment. We are proud to accompany Central Region Brewery on their development journey and pledge to continue providing advanced and sustainable technological solutions for them in the future.

>>> Please contact us

We are confident that DIVI Group will be your trustworthy partner in providing industrial boiler solutions.

For more detailed information about our products and services, please contact us through the following contact information:

DIVI GROUP CO., LTD (DIVI GROUP)

+ Address: 588 Pham Van Chieu, Ward 16, Go Vap District, Ho Chi Minh City

+ Hotline: (+84) 942 488 818

+ Email: ceo@divigroup.com.vn

+ Website: www.divigroup.com.vn

EN

EN