VIET BAC PLYWOOD LIMITED LIABILITY COMPANY

-

Designing & creating

According to standards TCVN 7704 - 2007 & TCVN 12728 - 2019 -

Design pressure

10 bar

-

Power consumption

<4 kW/MkCal -

Boiler capacity

4 MkCal/hour

-

Total amount of steam supplied

35,000 MkCal/year -

Fuel

Chopped veneer

DETAILS DESCRIPTION

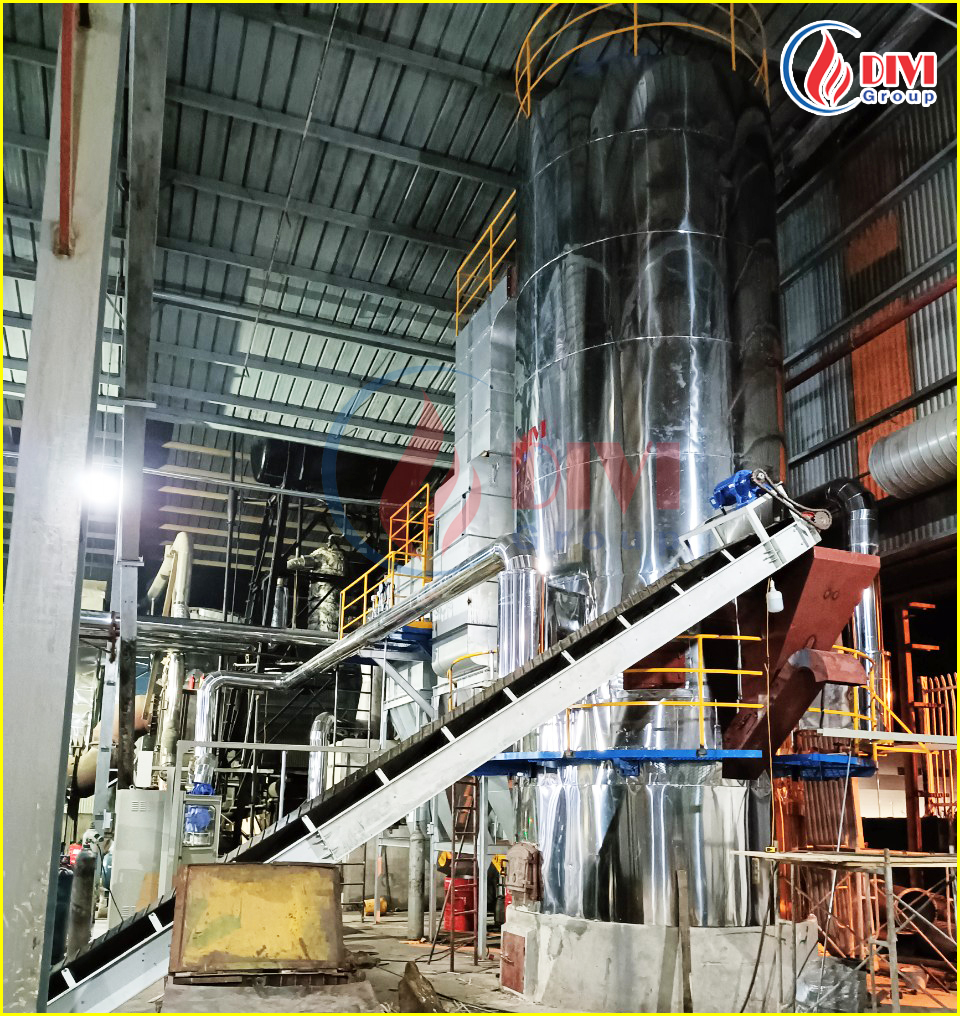

DIVI Group has recently undertaken a project involving the design, installation, and technology transfer of a heat transfer oil boiler system for Viet Bac Plywood Limited Liability Company. The project focuses on enhancing the efficiency of the wood processing industry while ensuring environmental sustainability.

Heat Transfer Oil Boiler System:

+ Under the contract between DIVI Group and Viet Bac Plywood LLC, the project aims to design, install, and transfer technology related to a heat transfer oil boiler system. This system includes a boiler with a capacity of 4 MkCal/hour, utilizing fuel derived from shredded veneer waste, with advanced technology to optimize energy conversion.

+ The boiler is manufactured according to the strictest standards, ensuring safety and efficiency during operation. With an annual heat output capacity of up to 35,000 MkCal, a design pressure of 10 bar, and energy consumption below <4 kW/MkCal, this system is located in Phu Xa Ward, Thai Nguyen City, Thai Nguyen Province. The factory specializes in producing plywood, veneer, and other thin wood products.

Application of the Heat Transfer Oil System in Wood Processing:

The wood processing process at Viet Bac Plywood LLC includes the following main stages:

1. Wood Preparation: Incoming wood is prepared and cut into appropriate sizes for the production process.

2. Wood Pressing and Heat Treatment: Wood is pressed and heat-treated in thermal furnaces to produce high-quality plywood, veneer, and pressed wood products.

3. Fuel Recycling: Veneer waste shredded after the wood pressing process can be used as fuel for the heat transfer oil boiler, creating a clean energy source and cost-saving measure.

Sustainability Commitment:

+ DIVI Group commits to continue supporting Viet Bac Plywood Limited Liability Company in optimizing production processes and ensuring a safe and sustainable working environment. We hope that this project will pave the way for a bright and sustainable future for both partners.

DIVI Group's Thermal Oil Boilers not only helps optimize the wood processing process but also plays a crucial role in environmental protection and energy conservation, supporting the sustainable development of the wood industry in Vietnam.

>>> Please contact us

We are confident that DIVI Group will be your trustworthy partner in providing industrial boiler solutions.

For more detailed information about our products and services, please contact us through the following contact information:

DIVI GROUP CO., LTD (DIVI GROUP)

+ Address: 588 Pham Van Chieu, Ward 16, Go Vap District, Ho Chi Minh City

+ Hotline: (+84) 942 488 818

+ Email: ceo@divigroup.com.vn

+ Website: www.divigroup.com.vn

EN

EN