While most factories are losing hundreds of thousands of dollars every year due to steam and heat loss, the PCHR Steam Saving System by DIVI delivers a breakthrough solution, helping reduce up to 20% of boiler fuel cost and achieve fast payback within 3–6 months.

OUTSTANDING BENEFITS

-

Save up to 20% of boiler fuel cost

-

Improve boiler operating efficiency and stability

-

Fast ROI in just 3–6 months (if condensate recovery ≥30%)

-

Reduce CO₂ emissions, environmentally friendly, compliant with QCVN 19:2024/BTNMT

-

Awarded USD 100,000 Innovation Grant by USAID

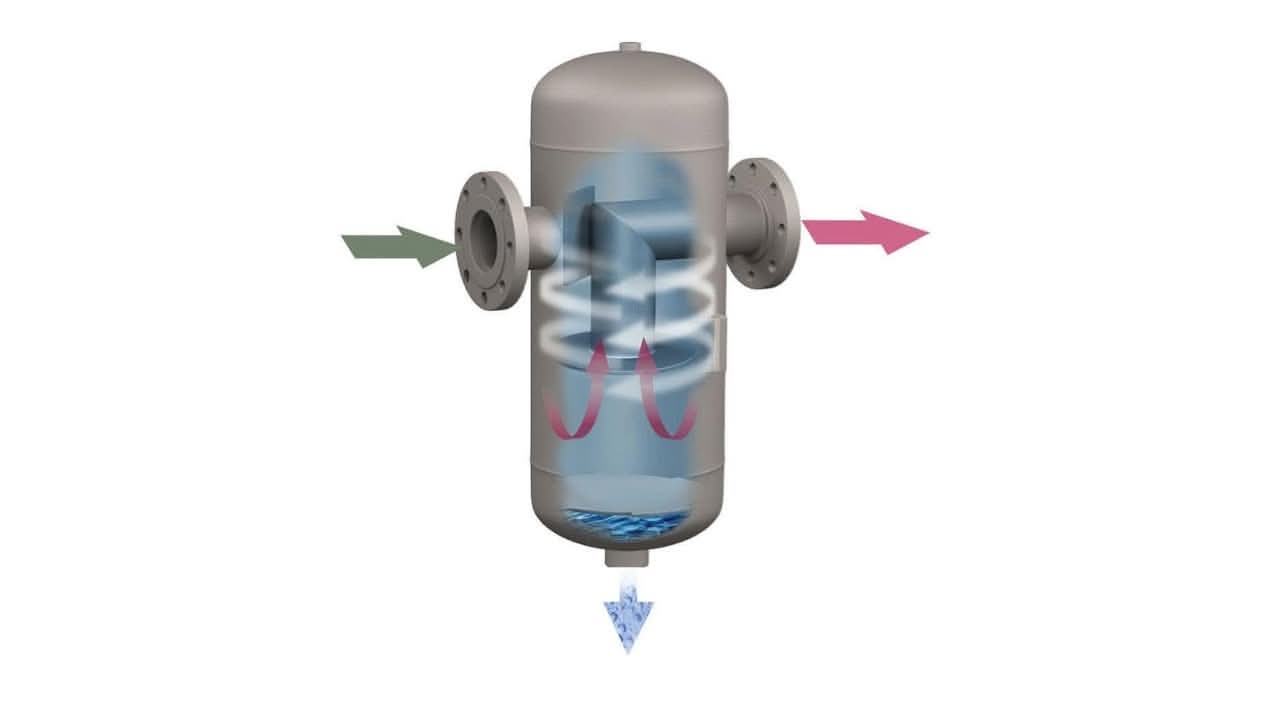

WORKING PRINCIPLE

-

Condensate from production line at approx. 4 bar & 144°C

-

If discharged into open tanks → heat loss & steam flashing

-

PCHR maintains pressure & temperature and pumps condensate directly back to boiler

→ Eliminates heat loss completely

TECHNICAL SPECIFICATIONS

| Capacity (m³/h) | Design Pressure (bar) | Max Pressure (bar) | Max Temperature (°C) | Shell Diameter (mm) | Shell Height (mm) |

|---|---|---|---|---|---|

| 3 – 5 | 950 | 1200 | 150 | 950 | 1200 |

| 5 – 8 | 1000 | 1300 | 150 | 1000 | 1300 |

| 9 – 12 | 1100 | 1400 | 150 | 1100 | 1400 |

| 13 – 15 | 1200 | 1500 | 150 | 1200 | 1500 |

BASIC DIMENSIONS

| Capacity (m³/h) | Volume (m³) | Thickness (mm) | Pump Capacity (m³/h) | Inlet (DN) | Steam Trap (DN) | Safety Valve (DN) |

|---|---|---|---|---|---|---|

| 3 – 5 | 1.05 | 10 | 7 | DN80 | DN40 | DN25 |

| 5 – 8 | 1.27 | 10 | 12 | DN100 | DN50 | DN32 |

| 9 – 12 | 1.65 | 12 | 15 | DN125 | DN65 | DN40 |

| 13 – 15 | 2.10 | 12 | 20 | DN150 | DN80 | DN50 |

PRACTICAL APPLICATIONS

-

TRISEDCO – Sao Mai Group (An Giang): Nearly 20% rice husk fuel cost saving

-

Applicable for: Food, Textile, Seafood, Rubber, Chemical, Fertilizer, Cement…

FAQ

1. How many factories are wasting energy due to steam loss?

About 99% of factories are still unaware of this solution.

2. How long is the ROI?

Only 3–6 months if condensate recovery ≥30%.

3. Is PCHR compatible with all boilers?

Yes, especially effective for boilers ≥5 tons/hour.

CONTACT

DIVI Group – Hotline/Zalo: 0942 488 818 (Mr. Hieu)

product video

Other Product

Blowdown tank

Boiler blowdown system ensures safe sludge discharge. Compare Blowdown Tank vs Separator with safety and efficiency insights. Read now!

EN

EN