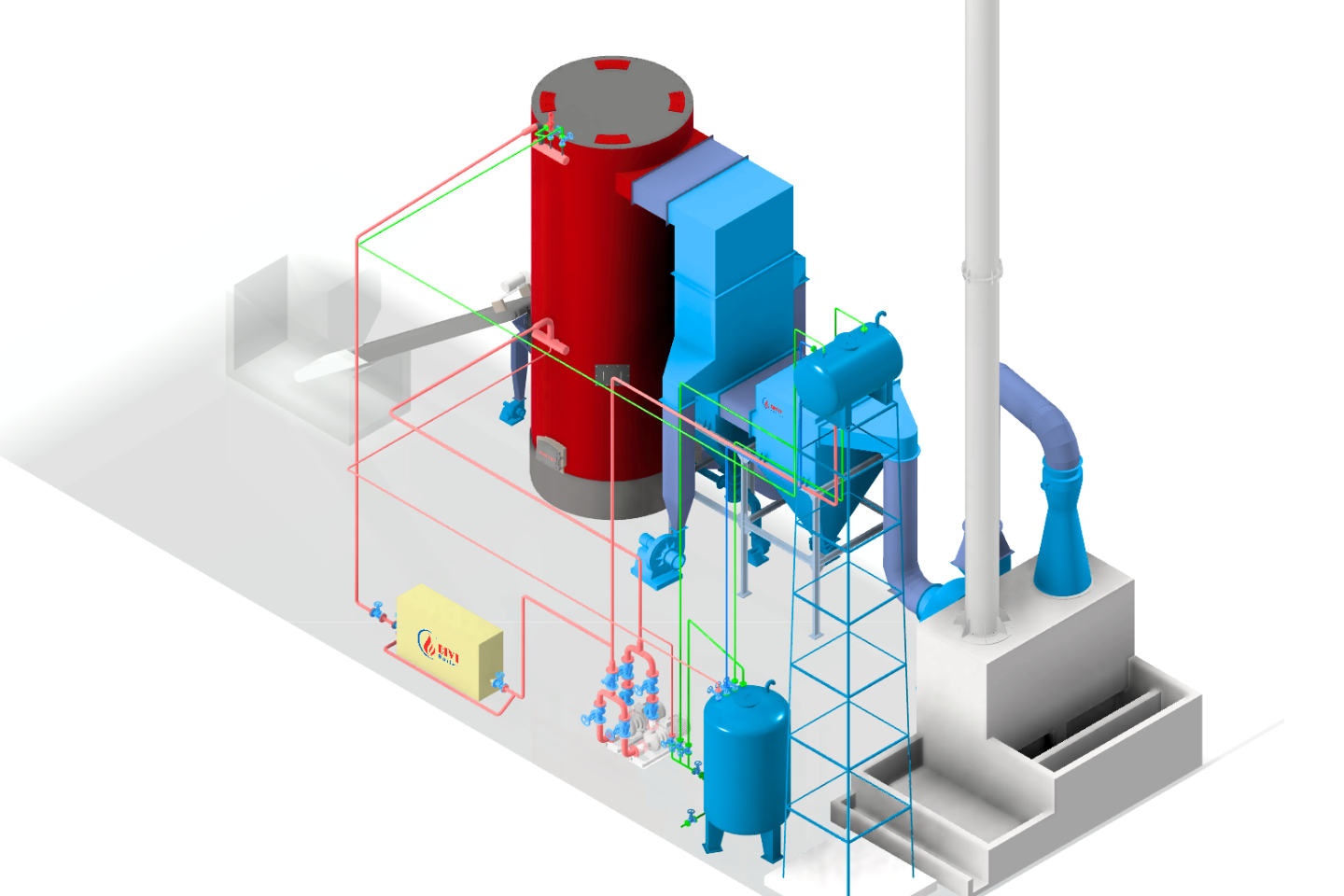

The DIVI DVG-VN compact biomass boiler is a next-generation steam boiler developed for small and medium-sized factories that require clean, stable, low-cost steam without the footprint and complexity of traditional fluidized bed biomass systems.

Unlike large-scale CFB biomass boilers, the compact DVG-VN model is space-optimized, factory-assembled, and fully integrated with automatic fuel feeding, ash removal, and emission-control systems — making it ideal for Southeast Asia and African industrial markets.

Key Technical Performance

| Specification | Value |

|---|---|

| Steam capacity: | 1.0 – 5.0 TPH (ton/hour) |

| Thermal efficiency: | ≥ 89% |

| Design pressure: | 1.25 MPa |

| Max. working pressure: | 1.0 MPa |

| Saturated steam temperature: | ~184°C |

| Fuel type: | Wood pellet, Cashew nut shell, PKS, Peat briquette |

Compatible with 4 Common Biomass Fuels

- Wood Pellet

- Cashew Nut Shell (CNS)

- Palm Kernel Shell (PKS)

- Peat Briquette

One boiler, multiple fuel options — helping factories reduce fuel cost using local biomass sources.

Technical Specifications (Compact Biomass Boiler DVG-VN)

| Model | Steam Capacity (kg/h) | Efficiency (%) | Design Pressure (MPa) | Max Working Pressure (MPa) | Steam Temp (°C) | Fuel Consumption (kg/h) | Silo Capacity (kg) | Weight (kg) | Overall Dimensions (mm) |

|---|---|---|---|---|---|---|---|---|---|

| DVG-VN-1.0 | 1,000 | ≥ 89 | 1.25 | 1.0 | 184 | 160 | 300 | 5,300 | 3500×1800×2800 |

| DVG-VN-2.0 | 2,000 | ≥ 89 | 1.25 | 1.0 | 184 | 360 | 335 | 6,195 | 4844×1983×3082 |

| DVG-VN-3.0 | 3,000 | ≥ 89 | 1.25 | 1.0 | 184 | 480 | 400 | 9,078 | 5660×2320×3290 |

| DVG-VN-4.0 | 4,000 | ≥ 89 | 1.25 | 1.0 | 184 | 680 | 735 | 11,530 | 6220×2550×3100 |

| DVG-VN-5.0 | 5,000 | ≥ 89 | 1.25 | 1.0 | 184 | 800 | 900 | 15,800 | 6550×2260×3200 |

Outstanding Advantages of the DVG-VN Compact Series

✅ 30% smaller footprint — easy installation inside existing factory layout

✅ High efficiency ≥ 89%, thanks to heat-recovery system & optimized furnace design

✅ Multi-fuel combustion – pellets, PKS, cashew shell, peat briquette

✅ Integrated emission control – cyclone + bag filter + NOx reduction module

✅ Automatic operation – fuel feeding, ash discharge, pressure & temperature control

✅ Lower OPEX – reduces fuel cost 20–40% vs diesel/LPG boiler

✅ Designed for regions with low infrastructure – simple transport, bolt-on assembly

Industrial Application Use-Cases

| Industry | Application | Key Benefits |

|---|---|---|

| Food & Beverage | Steaming, cooking, sterilizing | Clean & stable steam |

| Textile & Dyeing | Drying, dye fix, finishing | Lower energy cost |

| Rubber & Chemical | Latex drying, molding | 20–30% OPEX reduction |

| Coffee & Agriculture | Crop and seed drying | Uses local biomass fuel |

Why Choose DIVI Group?

- 15+ years of industrial boiler design & operation experience

- 5-year warranty on pressure body + 24/7 technical support

- Steam-as-a-Service (SaaS) option – no CAPEX required

- Complete energy solution: design → installation → maintenance → operation support

Other Product

Electric Resistance Steam Boiler DIVI DVG-LD

Biomass-fired fluidized bed boiler

In countries with a variety of agricultural and forestry waste products like rice husk, sawdust, cashew nut shell, chopped wood, coffee husk... with large and stable outputs like Vietnam, the choice of "Biomass-fired Fluidized Bed Boilers" is the most optimal solution, offering the highest economic efficiency among all current boiler investment options.

Biomass-fired Thermal Oil Boiler

Biomass-fired Thermal Oil Boilers" manufactured by DIVI Group have the same advantages as the "Fluidized Bed Biomass Boilers" technology. The only difference is the medium used by the Thermal Oil Boiler is heat transfer oil, whereas the Fluidized Bed Boiler uses water vapor.

Oil-Fired & Gas-Fired Steam Boiler

Are you looking for an oil-fired or gas-fired steam boiler that helps save fuel while ensuring high performance? With advanced combustion technology, this is an ideal solution for various industries — optimizing operating costs while meeting strict production demands.

EN

EN